A Deep Dive into Marine Coatings for Max Fuel Savings

Ever calculated the staggering cost of fuel for your commercial fleet? It’s often the single largest operational expense, threatening profitability and intensifying pressure to cut costs. But what if the solution wasn’t just about tweaking engine settings or optimizing routes, but about the very surface your vessel travels on?

Fuel saving marine coatings are a sophisticated, high-impact technology specifically engineered to dramatically improve a vessel’s fuel efficiency by optimizing its interaction with water. This article will provide a detailed exploration of two primary drivers of these savings—antifouling and foul-release technologies—unveiling how these advanced hull coatings revolutionize fuel efficiency, reduce operational costs, and drive your fleet towards a more sustainable future.

![[Image Placeholder]> Title: The Silent Drain: Biofouling vs. Smooth Hull Efficiency> Description: This illustration vividly contrasts a heavily biofouled ship's hull, showing the turbulent water flow and increased drag it causes, against a clean, advanced-coated hull with laminar flow and minimal drag, highlighting the critical difference in fuel efficiency. [Image Placeholder]> Title: The Silent Drain: Biofouling vs. Smooth Hull Efficiency> Description: This illustration vividly contrasts a heavily biofouled ship's hull, showing the turbulent water flow and increased drag it causes, against a clean, advanced-coated hull with laminar flow and minimal drag, highlighting the critical difference in fuel efficiency.](https://jdmarinepaint.com/wp-content/uploads/2025/08/未命名设计-copy46.png)

Before we dive into the solutions, it’s crucial to understand the silent, persistent enemy lurking beneath the waterline. Uncovering the truth about biofouling is the first step toward unlocking profound efficiency gains for your commercial vessels.

What is Biofouling, and Why Is It the Enemy of Efficiency?

Imagine your vessel, sleek and optimized, suddenly having to push through a sticky, uneven blanket. That’s essentially what biofouling does to a hull, creating an invisible but powerful force that works against every knot of speed, silently siphoning fuel and profits. Can something as innocuous as marine growth truly have such a devastating economic and environmental impact? The answer is a resounding yes.

Biofouling refers to the accumulation of marine organisms—from microscopic bacteria and diatoms forming a "slime layer" to macroscopic algae, mussels, and barnacles—on submerged surfaces of vessels. This biological growth significantly increases the hull’s roughness, leading to a dramatic rise in hydrodynamic drag. Even a thin layer of slime can increase fuel consumption by over 15%, while heavier fouling can escalate this penalty to 40% or more. This isn’t just about drag; severe fouling can also lead to the transfer of invasive aquatic species, posing an ecological threat that organizations are committed to solving by protecting marine environments from invasive species. The risk and intensity of biofouling vary globally, with warmer, nutrient-rich waters (such as tropical and subtropical regions) presenting a higher risk compared to colder seas.

The Hydrodynamic Impact of Fouling

The direct correlation between hull surface condition and fuel consumption is a fundamental principle of naval architecture. A perfectly smooth hull allows water to flow past it with minimal frictional resistance, maintaining laminar flow. However, biofouling disrupts this ideal.

How Drag Increases:

- Microbial Slime: The initial layer of bacteria and extracellular polymeric substances (EPS) creates a sticky, uneven surface, increasing turbulent flow and minor frictional drag.

- Algae and Weed Growth: As larger, filamentous organisms attach, they add volume and create significant irregularities, further disrupting water flow and substantially increasing drag.

- Hard Fouling (Barnacles, Mussels): These organisms present a highly irregular, rigid surface profile. Each barnacle acts like a tiny anchor, creating immense turbulence and causing a dramatic surge in hydrodynamic drag.

This increased drag means the vessel’s engines must exert more power to maintain a desired speed, directly translating to higher fuel consumption, increased operational costs, and elevated greenhouse gas emissions.

How Has Antifouling Coating Technology Evolved for Better Protection?

For centuries, shipowners have battled biofouling. Early solutions were rudimentary, often toxic, and not particularly effective. With today’s stringent environmental regulations and the pressing need for fuel efficiency, are we still relying on old-school paint, or has the science caught up? The history of antifouling is a testament to continuous innovation, driven by both economic necessity and environmental responsibility.

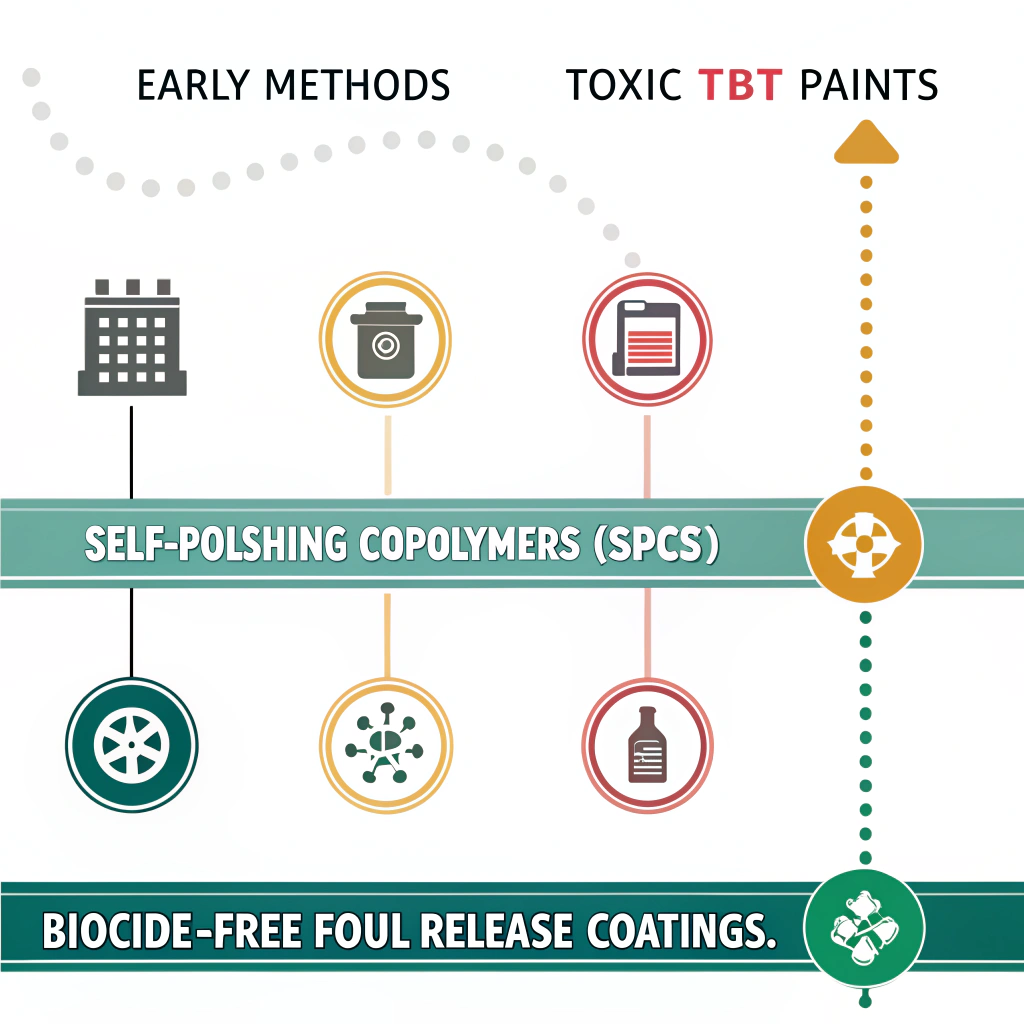

The evolution of antifouling coatings has moved from highly toxic, broad-spectrum biocides to sophisticated, controlled-release systems. The pivotal moment came with the ban on tributyltin (TBT) in the early 2000s, which spurred the development of more environmentally conscious and highly effective alternatives. Today’s dominant technology, Self-Polishing Copolymers (SPCs), represents a significant leap forward. At JDmarine, our commitment to cutting-edge solutions is evident in products like our long-lasting JD744 Chlorinated Rubber Antifouling Paint, which consistently releases antifouling agents to prevent marine growth, ensuring a cleaner hull and sustained vessel performance, especially in hot and subtropical waters. Similarly, our JD753 Tin-free self-polishing antifouling paint offers continuous protection through its unique self-polishing action, maintaining a smooth hull and preventing adhesion of marine organisms even in challenging conditions.

Self-Polishing Copolymers (SPCs)

Self-Polishing Copolymers (SPCs) are a cornerstone of modern antifouling technology. These coatings are engineered to gradually "polish" or ablate in a controlled manner as the vessel moves through water.

Mechanism of Action: SPCs work through a precisely timed chemical reaction with seawater. As the outermost layer of the paint slowly dissolves, it continuously releases small quantities of biocides (such as cuprous oxide) into a micro-layer of water near the hull. This creates an inhospitable environment that deters or kills fouling organisms before they can firmly attach. Meanwhile, the ablative action simultaneously maintains a smooth hull surface, preventing the buildup of surface roughness and ensuring sustained low friction. For effective, long-term prevention of marine growth, especially in challenging waters, our JD744 Chlorinated Rubber Antifouling Paint provides durable biocide release. For those seeking advanced, tin-free options that maintain a polished surface over an extended period, the JD753 Tin-free self-polishing antifouling paint is an excellent choice.

| Benefits and Limitations: | Aspect | Self-Polishing Copolymers (SPCs) |

|---|---|---|

| Benefits | – Highly effective across a wide range of operational profiles. – Controlled biocide release ensures consistent protection. – Self-smoothing action helps maintain low drag. – Long service life (up to 5 years). |

|

| Limitations | – Still rely on biocides, raising some environmental concerns. – Performance can be affected by very long idle periods. – Disposal of biocide-containing waste needs careful management. |

What Are Foul-Release Coatings, and How Do They Offer Biocide-Free Fuel Savings?

In an era demanding ever-increasing environmental responsibility, the concept of biocides in marine paints faces scrutiny. Is it truly possible to prevent marine growth and achieve substantial fuel saving marine coatings without resorting to chemicals that actively kill organisms? Many shipowners question the efficacy of a "non-stick" solution, especially given the aggressive nature of marine biofouling.

Foul-release coatings represent a revolutionary, biocide-free approach to preventing marine biofouling, relying instead on the principle of low surface energy to create an ultra-slick, non-stick surface that marine organisms simply cannot adhere to. This technology is a game-changer for fuel saving marine coatings, particularly for vessels with active trading patterns. By minimizing the adhesion strength of fouling, these coatings allow organisms to be easily dislodged by the vessel’s movement through water (hydrodynamic forces), maintaining a clean, smooth hull and ensuring maximum fuel efficiency without chemical leaching.

The Principle of Low Surface Energy

The core of foul-release technology lies in creating a hull surface with extremely low surface energy. This property minimizes the interfacial tension between the coating and marine organisms, making it incredibly difficult for them to establish a strong, permanent bond. Organisms may attempt to settle, but their adhesion is so weak that even minor water flow or vessel movement is enough to dislodge them.

Silicone-Based Foul-Release Coatings

How They Work: Silicone-based foul-release coatings derive their properties from the unique non-stick characteristics of silicone polymers. They form an elastic, super-smooth, and extremely low-friction surface. This slickness reduces the attachment strength of marine organisms, which are then naturally shed when the vessel reaches a certain speed, typically between 10-15 knots.

Advantages:

- Exceptional Fuel Savings: By preventing any significant biofouling, they maintain an ultra-smooth hull, leading to substantial reductions in hydrodynamic drag and impressive fuel savings.

- Biocide-Free: Environmentally friendly, as they contain no active biocides, aligning with strict environmental regulations.

- Long Service Life: Can offer impressive durability, often lasting for 5 years or more, reducing dry-docking frequency.

Considerations:

- Mechanical Resistance: Silicone coatings can be softer than traditional paints, making them potentially more susceptible to mechanical damage (e.g., from anchors, tug boats).

- Vessel Activity: Most effective on vessels with consistent activity and higher speeds; performance can degrade during extended idle periods or very slow steaming, as the self-cleaning mechanism relies on water flow.

Fluoropolymer Foul-Release Coatings

Fluoropolymer coatings share the non-stick principles of silicone but offer distinct advantages.

- Unique Properties: These materials are known for their exceptional chemical resistance, UV stability, and often, a harder, more durable finish compared to silicones. Our JDFT810 Fluorocarbon Topcoat is an example of a high-performance topcoat that leverages some of these properties for enhanced durability, providing superior weather and salt spray resistance over an extended period.

- Comparison: While typically more expensive, fluoropolymers can offer enhanced mechanical durability, making them suitable for high-stress areas or vessels operating in conditions where abrasion is a concern.

Hard Foul Release Coatings

A growing segment within foul-release technology, hard foul-release coatings combine the non-stick properties of traditional foul-release systems, but with significantly enhanced durability. These coatings are engineered to withstand regular abrasive forces, including aggressive in-water hull cleaning. This makes them ideal for vessels with varied operational profiles, including those that experience long idle periods and require more frequent cleaning maintenance. These robust solutions ensure that the benefits of foul-release technology can be extended to a wider range of vessel types and operating conditions. Furthermore, the complete coating system’s integrity relies on robust foundational layers, such as our JDH825 Solvent-Free Epoxy Tie Coat, which ensures strong adhesion between primers and the topcoats for a long-lasting protective system.

What Tomorrow’s Fuel Saving Marine Coatings Look Like?

We’ve explored how current technologies are saving fuel and protecting the environment, but the pace of innovation in the maritime industry is relentless. What cutting-edge advancements are on the horizon, and how will they further enhance the performance of fuel saving marine coatings? Shipowners and operators need to look beyond today’s solutions to prepare for future efficiency demands and regulatory landscapes.

The future of fuel saving marine coatings is being shaped by breakthrough innovations that will lead to even smarter, more durable, and environmentally inert solutions. From the microscopic precision of nanotechnology to biomimetic designs inspired by nature, and advanced systems that work in concert with engineering solutions like air lubrication, tomorrow’s coatings promise unprecedented levels of drag reduction and hull optimization. These innovations underscore a continuous drive toward maximizing vessel performance while minimizing environmental impact.

Innovations on the Horizon

The lab is where the future is born. Look for advancements in:

- Nanotechnology: Incorporating materials like graphene or carbon nanotubes could create coatings that are exceptionally strong, smooth, and resistant to damage and fouling.

- Smart Coatings: Imagine a coating that can sense the build-up of a slime layer and release a targeted burst of biocide or change its surface texture to dislodge it. Self-healing coatings that can repair minor scratches to prevent corrosion are also under development.

- Energy-Harvesting Coatings: While still largely conceptual, research is exploring coatings that could harvest energy from the vessel’s motion or temperature differentials, contributing to the ship’s power needs.

Integration with Hull Performance Monitoring

The biggest shift will be the integration of coating technology with data. Hull and propeller performance monitoring systems use sensors to track key metrics like fuel consumption, ship speed, and engine power in real-time. By correlating this data with the known performance of the hull coating, operators can:

- Verify ROI: Precisely measure the fuel savings delivered by the coating.

- Optimize Cleaning Schedules: Proactively schedule in-water hull cleaning when performance data shows an increase in drag, rather than waiting for a scheduled dry-docking.

- Inform Future Choices: Use historical performance data from across the fleet to make smarter decisions about which coatings to apply to which vessels.

Performance Measurement and Verification: How to Assess the Efficacy of Fuel Saving Marine Coatings?

In an industry where every percentage point of efficiency translates to millions in savings, how can shipowners be certain that fuel saving marine coatings actually deliver on their promises? With significant investments at stake, simply taking a manufacturer’s word isn’t enough. There’s a critical need for objective, verifiable data to prove the efficacy of these advanced solutions.

Performance measurement and verification for fuel saving marine coatings have become increasingly scientific and standardized. The industry relies heavily on sophisticated hull performance monitoring systems that track key parameters like speed, power, and fuel consumption in real-time. This data is then rigorously analyzed, often in accordance with international standards like ISO 19030, to quantify the actual reductions in drag and fuel usage. Manufacturers verify their claims through extensive sea trials, computational fluid dynamics (CFD) modeling, and long-term in-service performance data, providing transparent and credible evidence of the substantial fuel savings these coatings achieve.

The Importance of Data and Standardization

- Hull Performance Monitoring Systems: These systems use a network of sensors (e.g., GPS, flowmeters, torque meters) to continuously collect data on a vessel’s speed, power output, fuel consumption, and environmental conditions. This data is crucial for establishing baseline performance and accurately measuring changes after a new coating application.

- ISO 19030 Standard: This international standard provides a clear, transparent framework for measuring changes in hull and propeller performance. It defines methodologies for data collection, filtering, and analysis, ensuring that performance claims are robust, comparable, and reliable across the industry.

- Verification of Claims: Manufacturers conduct sea trials, comparing a vessel’s performance before and after coating application. This, combined with advanced data analytics and adherence to standards like ISO 19030, allows for credible verification of stated fuel savings, which can range significantly depending on the coating and operational profile.

Practical Considerations for Adopting Advanced Marine Coatings

Considering the undeniable benefits of advanced fuel saving marine coatings, the next logical step is adoption. However, for a commercial vessel operator, this isn’t a simple paint job; it involves strategic planning, significant investment, and operational adjustments. What are the crucial practical considerations for ensuring a successful transition to these high-performance systems?

Making the switch to advanced marine coatings requires meticulous planning, with surface preparation standing out as the absolute cornerstone for optimal results. Even the most technologically advanced coating will underperform, or worse, fail prematurely, if the underlying hull is not properly prepared. Beyond application, operators must consider the long-term economic and environmental payoff, understanding that the initial investment yields substantial dividends through reduced fuel costs, extended dry-docking intervals, and enhanced regulatory compliance. Our JDC43-31 Alkyd Hull Paint is a high-performance topcoat with excellent adhesion, flexibility, weather, and protective properties, but its performance also relies on good primers and prior treatment.

Key Factors for Your Decision Matrix

To ensure you make the optimal choice, consider the following:

| Factor | Key Questions to Ask | Coating Implications |

|---|---|---|

| Vessel Type & Trading Patterns | What is the vessel’s average speed? Does it have long idle periods? Does it operate on fixed routes or tramp? | High-speed vessels benefit most from low-friction foul-release coatings. Vessels with long idle periods or slow speeds may need a robust biocide-release SPC to prevent fouling when stationary. |

| Operating Environment | Will the vessel operate in warm, tropical waters with high fouling risk, or colder seas? | Warmer waters accelerate biofouling growth, demanding a more powerful and effective antifouling solution. The choice of biocide or foul-release technology must match the regional fouling challenge. |

| Budget & Goals | What is the upfront budget? What is the target ROI and service interval (e.g., 3 or 5 years)? | While premium coatings have a higher initial cost, their superior fuel savings and longer life deliver a lower total cost of ownership. Economical options like our JDL44-83 Bituminous Antifouling Paint can be effective for shorter service intervals on smaller vessels. |

| Surface Preparation & Application | What is the condition of the hull? Do you have access to a yard capable of high-quality application? | The success of any coating system is founded on proper surface preparation. All rust, old paint, and contaminants must be removed to the specified standard (e.g., Sa 2.5). Expert application is vital to achieve the correct film thickness and ensure system integrity. For more on the technical side of preparation, learning about coating performance and maintenance from industry authorities is invaluable. |

Long-Term Economic and Environmental Payoff

The decision to invest in premium fuel saving marine coatings is a long-term strategic one. While the upfront costs might seem higher, the lifecycle benefits are substantial. Significant fuel savings, reduced dry-docking frequency (and associated downtime), and lower maintenance needs translate into a compelling total cost of ownership. Moreover, utilizing eco-friendly, biocide-free, or low-VOC coatings aligns your fleet with global sustainability goals and rapidly evolving environmental regulations, enhancing your brand reputation and future-proofing your operations.

Surface Preparation is Key

The adage "preparation is everything" holds particularly true for marine coatings. The performance and longevity of any coating system, from our high-performance antifouling paints to durable topcoats like JDC43-31 Alkyd Hull Paint, depend entirely on the quality of the surface preparation.

- Cleaning and Degreasing: All contaminants—oil, grease, salt, and loose rust—must be thoroughly removed. High-pressure fresh water washing is often the first step to remove salts and loose marine growth.

- Abrasive Blasting: For new constructions or significant repairs, abrasive blasting to a high standard (e.g., Sa 2.5) creates the optimal profile for coating adhesion. Our JDH815 Iron Oxide Red Epoxy Primer is designed to work effectively on steel surfaces prepared to this standard, providing a robust anti-corrosive foundation.

- Tie Coats: For overcoating pre-existing systems or ensuring compatibility between different paint types, a specialized tie coat like our JDH263 Epoxy Tie Coat can be essential for strong adhesion.

- Application Expertise: Correct film thickness, ambient conditions, and curing times are critical. Professional application ensures the coating system achieves its full intended performance. More on best practices for coating performance and maintenance is readily available from industry experts.

FAQs on Antifouling and Fuel Saving Coatings

1. What is the difference between antifouling and foul-release coatings?

Antifouling coatings work by releasing biocides to prevent marine organisms from attaching to the hull. Foul-release coatings, on the other hand, create a smooth, non-stick surface with low surface energy, making it difficult for organisms to adhere, and they are typically shed by the vessel’s movement through water.

2. Are foul-release coatings effective at low speeds or during idle times?

Foul-release coatings are generally most effective on vessels with consistent activity and higher speeds, as their self-cleaning mechanism relies on hydrodynamic forces. During long idle periods or very slow speeds, their performance can be reduced, and some growth may occur, requiring active hull cleaning.

3. Can you clean a foul-release coating?

Yes, foul-release coatings, especially hard foul-release types, can be cleaned. Their durable nature allows for in-water cleaning without damaging the coating, helping to maintain performance even after periods of low activity or heavy fouling exposure.

4. How do you measure the fuel savings from a marine coating?

Fuel savings are typically measured using hull performance monitoring systems that track a vessel’s speed, power, and fuel consumption over time. Data is analyzed according to industry standards like ISO 19030 to calculate the reduction in drag and associated fuel use.

5. What regulations govern the use of antifouling paints?

The use of antifouling paints is primarily governed by the International Maritime Organization (IMO) through its International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention). This convention, along with regional regulations, dictates which biocides are permitted and promotes the development of environmentally safer alternatives. Compliance with International Maritime Organization (IMO) regulations is mandatory.

Conclusion

Embracing advanced fuel saving marine coatings is an essential step towards optimizing operational efficiency, ensuring regulatory compliance, and securing a sustainable future for your commercial fleet.

![]()