The Ultimate Guide to Marine Paint for Maintenance: Protecting Your Investment

Is your vessel losing its battle against the harsh marine environment? Neglecting paint maintenance leads to costly corrosion, stubborn fouling, and diminished value.

Marine paint for maintenance is your first line of defense, a specialized coating system designed to protect your vessel from the relentless attack of saltwater, UV radiation, marine growth, and abrasion. It’s not just about aesthetics; it’s a critical investment in your boat’s longevity, performance, and structural integrity. Properly maintained paintwork, utilizing high-quality products like those from JDmarine Paint , prevents costly repairs down the line, ensures your vessel operates efficiently by reducing drag from fouling, and preserves its resale value. From advanced antifouling paint on the hull to durable topcoats on the deck and superstructure, each layer plays a vital role in a comprehensive coating system (marine). For instance, our Epoxy series offers exceptional corrosion prevention (marine) as a primer, while our Antifouling series excels at marine growth prevention. Understanding and applying the right marine coatings during routine maintenance is fundamental to safeguarding your maritime asset.

This guide will delve deeper into why selecting and applying the correct marine paint for maintenance is non-negotiable for any responsible boat owner. We’ll explore the types of paints, application best practices, and how to extend the life of your protective coatings, with insights into how JDmarine Paint’s specialized formulations can benefit your vessel.

Why is Choosing the Right Marine Paint for Maintenance So Crucial for Your Vessel’s Longevity?

Ever wondered if you’re using the best paint for your boat’s upkeep? Choosing incorrectly can lead to premature coating failure, insufficient protection against harsh marine elements like saltwater and UV rays, and ultimately, more frequent, costly, and time-consuming repaint jobs. You might see issues like blistering paint (marine), peeling paint (marine), or rapid barnacle and algae accumulation, all because the initial choice wasn’t optimized for your vessel’s specific needs and operating environment. This oversight can significantly shorten your boat’s operational lifespan and diminish its value.

Choosing the right marine paint for maintenance is paramount because it directly impacts your vessel’s structural integrity, performance, and overall lifespan. A suitable coating system (marine), including the correct marine primers and topcoats, provides tailored vessel protection. For instance, antifouling paint, like our effective JDmarine Paint Antifouling series (e.g., JD753 Tin-Free Self-Polishing Antifouling Paint or JD744 Chlorinated Rubber Antifouling Paint), is essential for boat hull maintenance below the waterline to ensure marine growth prevention, which can increase drag and fuel consumption. Above the waterline, UV resistant marine paint, such as our durable JDmarine Paint Polyurethane topcoats (like JD918 Acrylic Polyurethane Hull Paint – yellowing resistant) or advanced JDFT810 Fluorocarbon Topcoat, protects against sun degradation, maintaining color and gloss. Different hull materials like fiberglass boat paint, aluminum boat paint, or steel boat paint require specific primers for optimal paint adhesion and corrosion prevention (marine). At JDmarine Paint, our extensive Epoxy series, including JDH06-4 Epoxy Zinc-Rich Primer for superior cathodic protection or JDH838 Galvanized Sheet Primer for specialized substrates, ensures excellent foundations. The right paint ensures marine paint durability, protecting your investment.

To further understand this, let’s break down the critical considerations:

Key Factors in Selecting Marine Paint for Maintenance?

Selecting the appropriate marine paint for maintenance isn’t a one-size-fits-all decision. Several factors must be carefully evaluated to ensure optimal performance and longevity. Neglecting these can lead to premature paint failure, inadequate vessel protection, and wasted resources. Consider JDmarine Paint’s comprehensive range, designed to meet diverse needs.

| Factor | Importance for Maintenance Painting | Key Considerations & JDmarine Paint Solutions |

|---|---|---|

| Substrate (Marine Painting) | The material of your boat (fiberglass boat paint, aluminum boat paint, steel boat paint, wooden boat paint) dictates primer and topcoat compatibility. | Adhesion properties, potential for corrosion prevention (marine). JDmarine Paint Epoxy series (e.g., JDH818 for low surface treatment, JDH835 for aluminum/steel) offers excellent adhesion and protection. Our JDC53-31 Red Lead Alkyd Primer is a traditional choice for steel. |

| Operating Environment | Where your boat spends most of its time (saltwater, freshwater, high UV exposure, abrasive conditions). | Saltwater resistant paint, UV resistant marine paint. JDmarine Paint Polyurethane topcoats (JD908, JD918) and JDFT810 Fluorocarbon paint offer superior UV and weather resistance. Our Antifouling series (JDL44-83, JD713, JD744, JD753) caters to various fouling conditions. |

| Type of Vessel & Usage | Commercial ship, yacht, small recreational boat; high speed vs. stationary. | Durability requirements, specific antifouling paint needs. JDmarine Paint offers robust systems for commercial vessels (e.g., high-build epoxies like JDH836 Solvent-Free Aluminum Iron Epoxy Primer) and high-finish options for yachts (Polyurethane and Fluorocarbon topcoats). |

| Regulatory Compliance | Local and international regulations regarding VOC (Volatile Organic Compounds) in marine paint and biocide content in antifouling. | Availability of eco-friendly marine paint options. JDmarine Paint is committed to developing lower VOC options and effective tin-free antifoulings like JD753. |

| Existing Coating System | Compatibility with previous paint layers if not stripping to bare substrate. | Adhesion tests, use of tie-coats. JDmarine Paint JDH263 Epoxy Tie Coat or JDH825 Solvent-Free Epoxy Tie Coat ensures excellent intercoat adhesion. |

| Desired Performance | Longevity, color retention, ease of cleaning, specific protective qualities (e.g., non-skid paint for decks). | Choice between single-part marine paint (1K) like our Alkyd series (e.g., JDC42-32 Alkyd Deck Paint) or Acrylic series (JDB902, JDB903) for ease of use, or two-part marine paint (2K) like our Epoxy or Polyurethane ranges for superior durability. |

| Budget & Application Method | Cost of materials and whether it’s DIY boat painting or professional boat painting. | JDmarine Paint offers a range of products balancing performance and cost. Our product data sheets provide clear application guidance for roller, brush, or spray gun. Consider our JDT111 Rustproof Oil for temporary protection. |

Understanding these factors allows for a more informed decision, ensuring the selected marine paint for maintenance, potentially from the trusted JDmarine Paint line, provides the best possible protective coatings for boats.

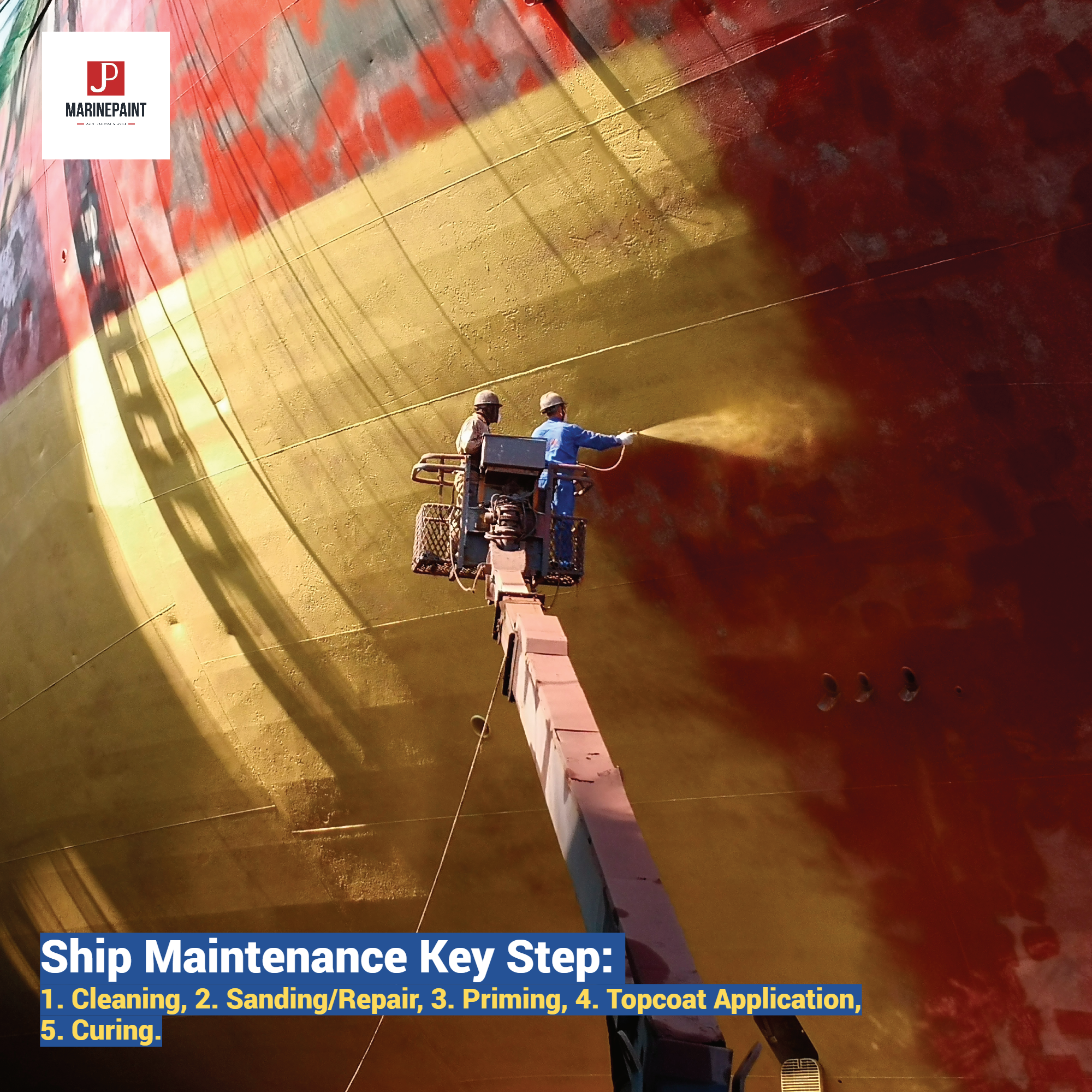

What are the Essential Steps for Successful Marine Paint Application During Maintenance?

Are you preparing to repaint your boat but worried about achieving a durable, professional finish? Skipping crucial steps or using incorrect boat painting techniques can lead to a host of problems such as poor paint adhesion, premature peeling paint (marine), or an uneven, unsightly finish. The effort invested in painting can be quickly undone if the surface preparation for marine paint is inadequate or the application process is rushed, turning a protective measure into a frustrating rework. This not only wastes valuable marine paint but also time and money.

Successful marine paint application during maintenance hinges on a methodical approach. The most critical phase is meticulous surface preparation for marine paint. This involves thoroughly cleaning the surface to remove contaminants like salt, grime, and old, flaking paint using techniques like sanding or scraping. Any existing boat paint repair needs must be addressed. Once prepared, applying appropriate marine primers, such as those from the JDmarine Paint Epoxy series (e.g., JDH815 Iron Red Epoxy Primer or JDH819 Epoxy Zinc Phosphate Primer for excellent anti-corrosion), is essential to ensure strong paint adhesion. Finally, the chosen marine topcoats (e.g., JDmarine Paint Polyurethane topcoats like JD908 Acrylic Polyurethane, or our Alkyd series like [JDC43-31 Alkyd Hull Paint](JDC43-31 Alkyd Hull Paint "JDC43-31 Alkyd Hull Paint")) should be applied according to manufacturer specifications, ensuring correct film thickness and allowing adequate drying/curing time between coats for optimal marine paint durability. Our "Paint and its Maintenance Guide" ( p.46-59 of your brochure) offers detailed advice.

Let’s delve deeper into these essential stages for achieving a lasting finish.

The Critical Role of Surface Preparation in Marine Paint Maintenance?

Many boat owners underestimate the importance of surface preparation, often leading to disappointing results and a shortened lifespan for their new paint job. A poorly prepared surface is the primary cause of most marine paint failures. As we emphasize at JDmarine Paint, proper prep is paramount, as detailed in our product datasheets and maintenance guides.

| Preparation Step | Description & Purpose | Key Materials/Tools | Why It’s Crucial for Marine Paint for Maintenance |

|---|---|---|---|

| Cleaning | Thoroughly wash to remove salt, dirt, grease, oil, and marine growth. | Boat soap, degreaser, pressure washer, scrapers | Ensures contaminants don’t interfere with paint adhesion. |

| Removing Old/Loose Paint | Scrape or sand away any flaking, peeling, or poorly adhered old paint. Feather edges of sound paint. | Scrapers, sanders (orbital, manual), sandpaper | Provides a stable, uniform surface. |

| Sanding | Abrade the entire surface to create a mechanical key for the primer and topcoat. Smooth out imperfections. | Sandpaper (various grits), sanding blocks, dust masks | Crucial for paint adhesion; a smooth, keyed surface allows the paint to grip effectively. |

| Repairing Damage | Fill gouges, cracks, or blisters. For gelcoat maintenance, repair chips and cracks. | Epoxy fillers, fairing compounds, gelcoat repair kits | Ensures a sound, smooth substrate (marine painting). Painting over damage compromises the protective barrier. |

| Solvent Wipe/Final Clean | Remove all sanding dust and any remaining contaminants with a specific paint thinner (marine) or surface prep solvent, like JDmarine Paint X-7 Epoxy Thinner for epoxy systems. | Lint-free rags, recommended solvent | The final step before priming; guarantees a perfectly clean surface for maximum paint adhesion. |

Proper surface preparation for marine paint is non-negotiable for achieving a durable and protective finish, especially when using high-performance coatings like JDmarine Paint’s Epoxy primers or Polyurethane topcoats.

Application Techniques: Achieving Optimal Results with Your Marine Paint?

Once the surface is impeccably prepared, the marine paint application itself requires care. JDmarine Paint products are designed for various application methods, and our technical data sheets provide specific guidance for each, such as using JDmarine Paint X-7 Thinner with our Epoxy series or J-10 Thinner with our Polyurethane series.

| Application Method | Pros | Cons | Best For | Tips for Marine Paint for Maintenance with JDmarine Paint |

|---|---|---|---|---|

| Brush | Good control, good for cutting in and small/complex areas. | Can leave brush marks, slower for large areas. | Small boats, trim, touch-ups, wooden boat paint details. Some JDmarine Paint Alkyd series products apply well by brush. | Use high-quality brushes. Apply thin, even coats. |

| Roller | Faster than brushing for large, flat areas. | Can create a stippled texture if not tipped off. | Large flat surfaces like hulls, applying JDmarine Paint Antifouling series or Alkyd topcoats like JDC43-31. | Choose solvent-resistant rollers. Follow with tipping off for gloss finishes. |

| Spray Gun | Fastest application for large areas, provides the smoothest, most professional finish. | Requires more skill, significant masking and prep. | Large vessels, achieving high-quality finishes with JDmarine Paint’s two-part Epoxy (e.g., JDH817 MIO Epoxy) and Polyurethane (e.g., JD918) systems. Also for our JDFT810 Fluorocarbon Topcoat. | Ensure proper ventilation. Follow JDmarine Paint data sheets for thinning, pressure, and nozzle size. E.g., our JDH912 Epoxy Potable Water Tank Special Paint is designed for airless spray. |

Always consult JDmarine Paint’s product data sheets for specific recommendations on temperature, humidity, overcoating times (like the 16-hour interval for JDH263 Epoxy Tie Coat before applying antifouling), and required film thickness (e.g., JDH836 can achieve 300µm DFT in one coat).

How Can You Maximize the Lifespan and Effectiveness of Your Marine Paint for Maintenance?

You’ve invested time and money in a fresh coat of marine paint for maintenance, perhaps using durable JDmarine Paint products, but how do you ensure it lasts? Simply painting your boat and forgetting about it can lead to premature degradation, allowing minor issues to escalate. This shortens the effective life of your protective coatings for boats.

Maximizing the lifespan of your marine paint for maintenance involves proactive inspection, cleaning, and timely touch-ups. A consistent marine maintenance schedule helps remove salt and pollutants that can degrade the paint surface. Promptly addressing minor damages prevents them from worsening. For antifouling paint, like our JDmarine Paint Antifouling series, periodic light cleaning of the waterline can help maintain its efficacy. This ongoing care, as outlined in the "Paint and its Maintenance Guide" from JDmarine Paint, is key to extending paint life (marine).

Let’s explore specific actions you can take to keep your paintwork in top condition.

Routine Care Tips for Preserving Your Maintained Marine Paint?

Consistent, gentle care can significantly extend the intervals between major repainting jobs. This is especially true for high-performance coatings like JDmarine Paint’s Polyurethane or Fluorocarbon topcoats.

| Care Tip | Description | Frequency | Benefit for Marine Paint Durability |

|---|---|---|---|

| Regular Cleaning / Washing | Gently wash painted surfaces with a soft brush or sponge and a mild, pH-neutral boat soap. Rinse thoroughly with fresh water. | After each use, or at least monthly. | Removes salt deposits and pollutants that can attack the topcoat. JDmarine Paint topcoats are designed for easy cleaning. |

| Avoid Harsh Chemicals/Abrasives | Do not use abrasive cleaners or strong solvents unless specified by the paint manufacturer. | Always. | Prevents scratching or chemically damaging the paint film. |

| Inspection for Damage | Regularly inspect all painted surfaces for chips, scratches, or wear. | Monthly, and after any potential impact. | Early detection allows for quick boat paint repair, preventing rust prevention (marine) failure. |

| Timely Touch-Ups | Address minor scratches promptly with the correct touch-up paint from your JDmarine Paint system. | As soon as damage is detected. | Seals the breach in the protective coatings for boats. |

| Waxing (for Gloss Topcoats) | Apply a quality marine wax to gloss topcoats like JDmarine Paint Polyurethane series (JD908, JD918) or JDFT810 Fluorocarbon Paint. | 1-2 times per season, or as recommended. | Adds an extra layer of UV protection and enhances gloss. |

| Covered Storage/Mooring (if possible) | If practical, storing your boat under cover. | When not in use. | Reduces direct exposure to UV radiation and weathering. |

These routine care practices are fundamental to getting the most out of your marine paint for maintenance.

Recognizing and Addressing Common Marine Paint Issues During Maintenance Checks?

Even with quality paints like those from JDmarine Paint, issues can arise. Early recognition during your marine maintenance schedule is key. Our product range, from the JDH06-4 Epoxy Zinc-Rich Primer to the JD918 Acrylic Polyurethane Hull Paint, is designed for durability, but understanding potential issues helps maintain them.

| Paint Issue | Common Causes | How to Address During Maintenance (Consider JDmarine Paint system compatibility) | Prevention for Future |

|---|---|---|---|

| Blistering Paint (Marine) / Osmosis | Trapped solvent or moisture; contamination. | Small blisters: sand back, clean, prime with a suitable JDmarine Paint Epoxy primer, and repaint. Widespread osmosis may need professional stripping and application of a barrier coat like JDH912 Epoxy for specific applications. | Thorough surface prep, correct solvent evaporation, use appropriate JDmarine Paint primers. |

| Peeling Paint (Marine) / Flaking | Poor paint adhesion due to inadequate surface prep, incompatible paints. | Scrape/sand, clean, prime with a compatible JDmarine Paint primer (e.g., JDH818 or JDH263 tie-coat), and repaint with a chosen JDmarine Paint topcoat. | Meticulous surface prep, use of correct JDmarine Paint primers and link coats, adhering to recoat times. |

| Chalking Paint (Marine) | UV degradation. | Wash. If severe, polish. If persistent, repaint with a high UV resistant marine paint like JDmarine Paint JD918 Polyurethane or JDFT810 Fluorocarbon. | Use high-quality, UV-resistant JDmarine Paint topcoats. Regular waxing. |

| Marine Growth (Barnacles, Algae) | Antifouling paint depleted or ineffective. | Scrub. If boat bottom paint is ineffective, haul out, clean, and reapply fresh JDmarine Paint Antifouling (e.g., JD753 Self-Polishing or JDL44-83 Asphalt based). | Regular use, periodic cleaning, timely reapplication of effective JDmarine Paint Antifouling. |

| Fading / Loss of Gloss | UV exposure, harsh cleaning. | Clean, polish, wax. JDmarine Paint Polyurethane and Fluorocarbon paints offer excellent gloss retention. | Use high-quality UV resistant JDmarine Paint topcoats. |

| Rust Prevention (Marine) Failure | Scratches on metal surfaces. | Remove rust, clean, apply a suitable JDmarine Paint Epoxy primer (e.g., JDH06-4 Zinc-Rich or JDH835 Aluminum Iron Epoxy for steel/aluminum), then topcoat. | Maintain intact paint film. Prompt touch-ups. Use JDmarine Paint’s robust anti-corrosive primer systems. |

Proactive inspection and addressing these issues promptly are key for coatings like JDmarine Paint’s Alkyd series (e.g., JDC53-35 primer, JDC43-31 topcoat) or more advanced systems.

Conclusion

Proper marine paint for maintenance, like the comprehensive systems from JDmarine Paint , is not an expense, but a vital investment. Protect your vessel effectively.

![]()