What is the Best Antifouling Paint of 2025? A Performance Review and Buyer’s Guide

Is marine biofouling slowing your boat and driving up fuel costs? Using the wrong hull protection can lead to expensive damage and constant, frustrating cleaning. The right antifouling paint system is your best defense.

The "best" antifouling paint is not a single product but a strategic choice tailored to your specific needs. Its performance depends entirely on your boat type, how you use it, the waters you frequent (salt, fresh, or brackish), and environmental considerations [21][22]. This 2025 buyer’s guide will help you navigate the top-performing technologies—from durable hard paints to consistent self-polishing coatings and innovative biocide-free options—to help you select the optimal hull protection for your vessel.

![[Image Placeholder]> Prompt: A dynamic photo of a sleek, modern powerboat cruising at speed, kicking up a clean wake. The water is crystal clear, showcasing a pristine, brightly colored antifouling-painted hull under the waterline. [Image Placeholder]> Prompt: A dynamic photo of a sleek, modern powerboat cruising at speed, kicking up a clean wake. The water is crystal clear, showcasing a pristine, brightly colored antifouling-painted hull under the waterline.](https://jdmarinepaint.com/wp-content/uploads/2025/07/a-dynamic-photo-of-a-sleek-modern-powerboat-cruis-2.png)

To make the right choice, you first need to understand the science that makes this underwater shield so effective against the constant assault of marine growth.

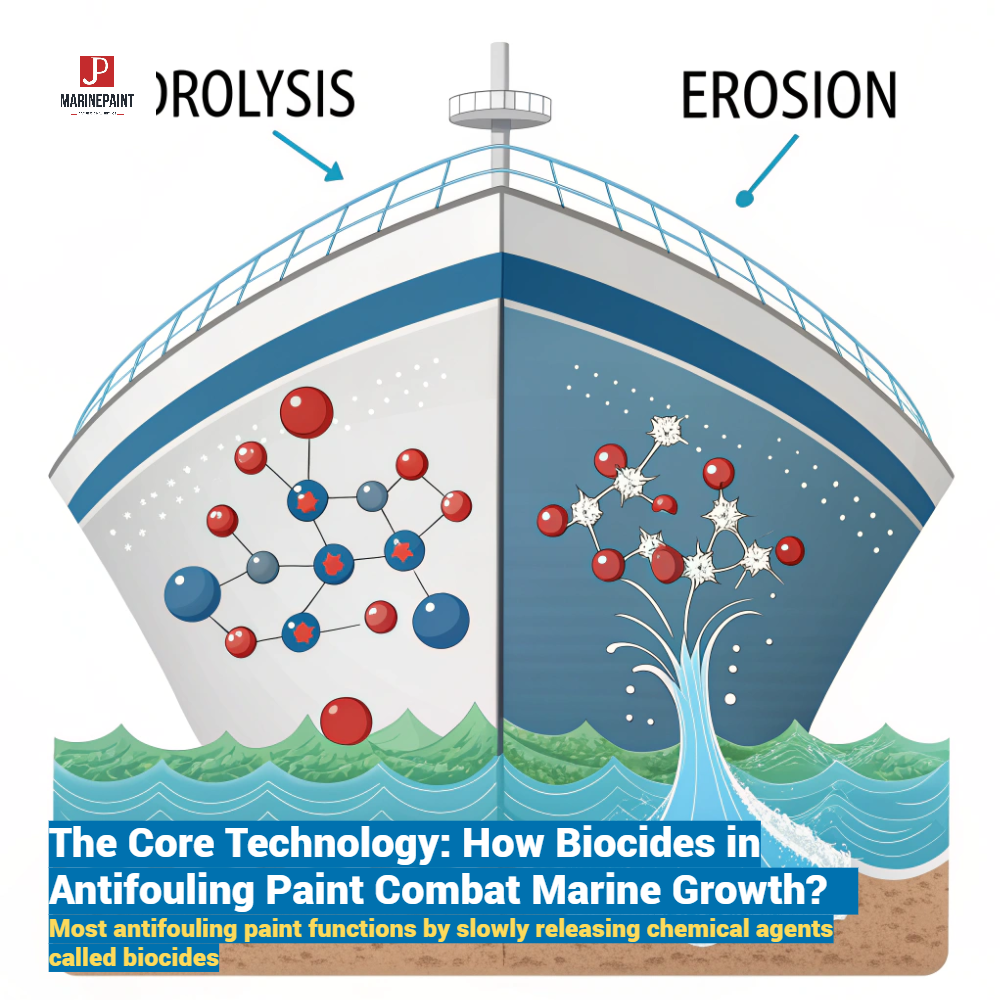

The Core Technology: How Biocides in Antifouling Paint Combat Marine Growth?

Have you ever wondered what’s actually happening on your hull’s surface to keep it so clean? It might seem simple, but it’s driven by complex chemistry. Without understanding how biocides work, you’re choosing a product blind, hoping it will be effective against the specific marine growth in your area. This can easily lead to premature fouling, poor vessel performance, and wasted money. Understanding the science of biocide release is the first step toward making an expert choice and ensuring your investment in hull protection pays off all season long.

Most antifouling paint functions by slowly releasing chemical agents called biocides, which create a hostile microscopic layer on the hull’s surface that prevents marine organisms from attaching [27]. This release is controlled through two primary mechanisms: hydrolysis, where the paint binder chemically reacts with water, or erosion, where the paint’s surface physically wears away. Copper has long been the industry’s standard biocide, typically in the form of cuprous oxide (氧化亚铜) for its broad effectiveness against fouling organisms like barnacles [4][5][13]. To combat a wider range of growth, especially soft growth like algae and slime, many modern paints also incorporate "booster" biocides [27]. However, the environmental impact of copper and other chemicals leaching into marine ecosystems is a significant concern, leading to stricter regulations and driving innovation toward more environmentally friendly, biocide-free technologies [26].

Head-to-Head Comparison: The Main Types of Antifouling Paint?

When you’re faced with a wall of hard, ablative, and biocide-free paints, how do you even begin to choose? Picking the wrong type for your boating style is a classic and costly mistake. A racing sailboat using a soft ablative paint will lose its smooth, fast finish, while a casual cruiser using a hard paint will face years of thick paint buildup and laborious sanding. You might want an eco-friendly option but worry it won’t be effective if your boat sits idle for weeks at a time. This confusion often leads to a poor investment and a frustratingly fouled hull by mid-season.

Selecting the right category of antifouling paint is the most crucial decision in your hull protection strategy. The three main types—hard, ablative (or self-polishing), and biocide-free—are engineered for very different applications and boater profiles [7][8][9]. Hard paints provide a tough, scrubbable finish that is perfect for high-speed or racing boats that are cleaned regularly [7][28]. Ablative paints offer consistent, often multi-season protection by wearing away over time, which prevents paint buildup and simplifies reapplication, making them ideal for most cruising vessels [8]. The newest category, biocide-free foul-release coatings, utilizes slick surface technology to prevent growth from getting a grip in the first place, presenting an excellent environmentally sound choice for boaters in sensitive waterways [26]. Your decision here will directly impact your boat’s performance, your annual maintenance workload, and the long-term cost of ownership.

Category 1: Hard Antifouling Paints (The Durable Defender)

Hard antifouling paints, also known as contact leaching paints, cure to a hard, durable finish like an epoxy [28]. The paint film is a porous matrix loaded with biocides, which leach out upon contact with water. Because the paint itself doesn’t wear away, it can be repeatedly scrubbed and cleaned without losing its effectiveness, making it the top choice for high-speed powerboats, racing yachts, and any vessel that is frequently hauled and cleaned mid-season [7]. The primary drawback is that once the biocides are depleted, a non-functional, porous layer of paint remains. This leads to a thick buildup of old paint over several seasons that eventually adds weight and must be completely sanded off—a very labor-intensive job.

Category 2: Ablative (Self-Polishing) Antifouling Paints (The Consistent Performer)

Ablative paints, or self-polishing copolymers (SPCs), are designed to wear away, or "ablate," at a controlled rate as the boat moves through the water [8]. This constant, gentle erosion continuously exposes a fresh, fully effective layer of biocide, ensuring reliable protection throughout the season, or even multiple seasons [13]. The major advantage is the elimination of paint buildup; preparing for reapplication is as simple as a pressure wash and a new coat. This makes them the ideal user-friendly choice for most cruising sailboats, motorboats, and even trailered boats [7]. A prime example is our JD753 Tin-free self-polishing antifouling paint [2], which is engineered using self-polishing copolymer resin for long-lasting and effective foul prevention [13].

Category 3: The New Wave – Biocide-Free Antifouling Coatings (The Eco-Conscious Choice)

Representing the future of hull protection, biocide-free coatings are the most environmentally friendly option [26]. Instead of using toxins to kill marine life, these coatings—which are typically silicone, hydrogel, or fiber-based—create an ultra-slick surface that organisms simply cannot adhere to. Any light fouling that does manage to attach is usually washed off as soon as the boat starts moving. This makes them ideal for high-use boats and for boaters in regions with strict environmental regulations, in alignment with the goals of the International Convention on the Control of Harmful Anti-fouling Systems (AFS). Their performance is highly dependent on regular use, so they may be less suitable for boats that remain stationary for long periods.

What are the Key Factors for Selecting Your Antifouling Paint?

You now understand the types of paint available, but how do you apply that knowledge to your specific boat? Choosing a product based on brand recognition or price tag alone is a significant gamble. An antifouling paint that works wonders for your friend’s boat in a warm saltwater marina might fail completely on your vessel in a cool, brackish river [21]. Ignoring crucial factors like water fouling intensity, your frequency of use, and even your boat’s hull material can lead to poor performance, galvanic corrosion, or inadvertently violating local environmental laws [24].

Selecting the optimal antifouling paint requires a careful evaluation of several key factors that create a complete picture of your needs. The best choice is always a tailored solution. You must consider your boat’s typical speed, the water conditions it lives in (saltwater, freshwater, or brackish) [21], the local fouling intensity (how aggressive the marine growth is in your area) [24], how frequently you use the boat, and its hull material. For example, aluminum hulls demand special copper-free paint to prevent severe galvanic corrosion [21]. Finally, you must be aware of local and international environmental regulations, which may restrict certain biocides, and adhere to environmental best practices for boaters for application and removal.

Boat Type, Speed, and Usage

A slow-moving displacement hull boat that spends most of its time at the dock will have different needs than a high-speed planing hull that is used every weekend. Ablative paints work best with some water flow to control their polishing rate, while frequent use is essential for biocide-free coatings to self-clean. Hard paints are best for very fast boats or boats that are raced and scrubbed, as their durable surface can withstand the pressure and friction [7].

Water Conditions and Fouling Intensity

The type and aggressiveness of marine growth vary dramatically between locations [24]. Warm, nutrient-rich saltwater typically creates the highest fouling pressure [21]. Freshwater has different types of growth, often more slime and algae. A paint with a powerful biocide package like our JD744 Chlorinated Rubber Antifouling Paint [2], formulated with cuprous oxide for long-term effectiveness, is ideal for these challenging environments [5]. In low-fouling areas, a more economical or less potent paint may be perfectly adequate.

Hull Material and Primer Systems

This is a critical safety and structural consideration.

- Aluminum: Never use a standard copper-based antifouling paint directly on an aluminum hull or outdrive. The interaction between copper and aluminum in water will cause rapid galvanic corrosion, destroying the metal [21]. You must use a copper-free antifouling paint or one that uses a less reactive biocide like cuprous thiocyanate.

- Steel & Iron: These hulls require a robust anti-corrosive primer system before any antifouling is applied [6]. A high-performance epoxy primer like our JDH819 Epoxy Zinc Phosphate Primer [9] creates an impermeable barrier that protects the steel from corrosion and provides a strong foundation for the antifouling paint.

- Fiberglass (GRP): Most antifouling paints are suitable for fiberglass. On new or bare GRP, it is essential to first apply an epoxy primer to prevent water absorption (osmosis) and ensure strong adhesion [21].

How Do You Maximize Your Investment with a Good Reapplication Strategy?

You’ve spent good money on the best antifouling paint for your boat and dedicated a weekend to careful application. Now what? Many boat owners mistakenly treat it as a "set and forget" solution, only to be disappointed when slime and barnacles appear before the season is over. Others reapply religiously every single year, potentially wasting money and effort when their premium paint was designed to last much longer. Without a clear and realistic strategy for maintenance and reapplication, you are either risking damage to your hull or throwing money away.

The longevity of your antifouling paint job depends on the product quality, the number of coats applied, and your local conditions, but a realistic expectation is anywhere from one to three seasons [29]. High-end, multi-season ablative paints are formulated for extended effectiveness, but no coating is truly "set and forget" [9]. Regular use of your boat is the best maintenance, as it helps ablative paints work correctly and helps slick, biocide-free coatings shed any light growth. For boats that sit for long periods, having a professional diver perform a gentle wipe-down can significantly extend the paint’s effective life. When budgeting for your antifouling, consider the long-term value. A more expensive paint that lasts two or three seasons often provides a better return on investment and less labor than a cheap paint that requires annual reapplication [9].

Have Questions About Antifouling? We Have Answers.

Even with all this information, specific, practical questions can linger. "Can I really just paint this new stuff over my old paint?" "Is that expensive can really worth the extra money?" "What’s the deal with painting an aluminum boat?" Guessing the answers to these critical questions can lead to disastrous and costly results—from paint peeling off in sheets to a severely corroded hull. You need clear, concise, and trustworthy answers to make your final decisions with complete confidence.

To help you finalize your choice, we’ve answered some of the most frequently asked questions about antifouling paint.

-

What is the best antifouling paint for aluminum boats?

You must use a copper-free antifouling paint. Alternatively, paints that use cuprous thiocyanate as the biocide are often formulated to be safe for aluminum, but always check the manufacturer’s label. Using traditional copper oxide paint will cause destructive galvanic corrosion [21]. -

Are expensive antifouling paints worth it?

Often, yes [9]. Premium paints typically use more effective biocides, more advanced self-polishing resins for multi-season protection, or innovative biocide-free technology. This translates to better performance, less work for you, and sometimes, a better choice for the environment [26]. -

What is the most environmentally friendly antifouling paint?

The most eco-conscious choices are the biocide-free, foul-release coatings that rely on a slick surface to prevent adhesion. -

Can I switch from hard paint to soft paint?

Yes. To switch from a hard paint to a soft (ablative) paint, you must sand the old hard paint thoroughly to create a rough "key" for the new paint to adhere to. Switching from soft to hard is more difficult and requires the complete removal of all old soft paint down to the primer to ensure the new hard layer has a stable foundation. For maximum compatibility when changing types, a tie-coat primer like our JDH263 Epoxy Tie Coat is highly recommended to bond the different layers together securely [9].

Conclusion: Your Boat’s Best Defense

The "best" antifouling paint of 2025 is not a one-size-fits-all product but a choice meticulously tailored to your vessel. By evaluating your boat type, usage, location, and local regulations, you can select the ideal hull protection. Investing in quality preparation and professional application is the final, crucial step to ensuring your choice delivers maximum performance and value, keeping your hull clean, fast, and efficient for seasons to come.

![]()