How do I prevent marine paint from peeling?

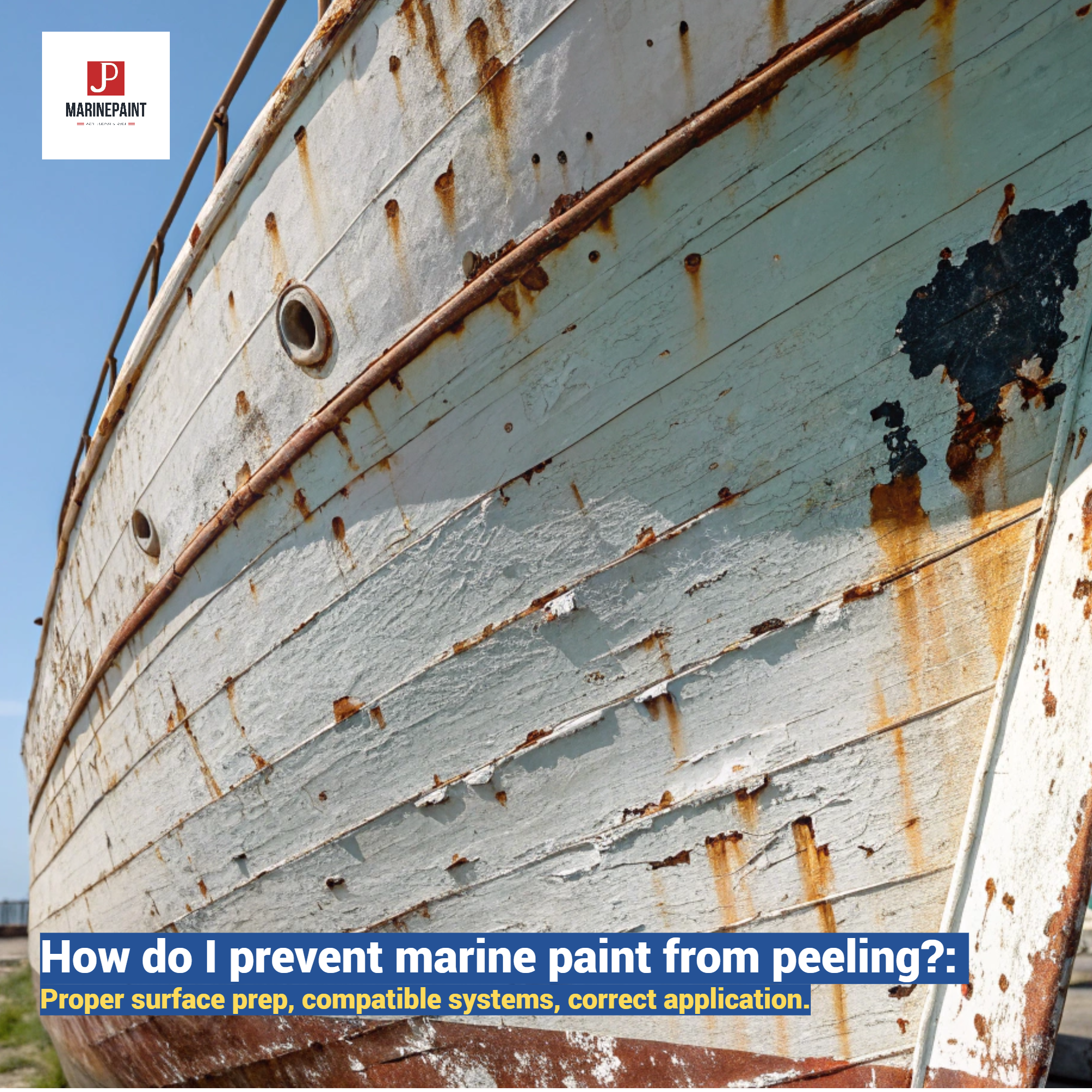

Frustrated by marine paint that bubbles, cracks, and peels prematurely? This common issue ruins aesthetics and, more importantly, exposes your vessel to corrosion and damage.

To effectively prevent marine paint from peeling, a multi-faceted approach focusing on three core pillars is essential: meticulous surface preparation for marine paint, the selection of a fully compatible coating system (marine), and adherence to correct marine paint application techniques. Peeling paint is most often a symptom of failure in one or more of these areas. Poor adhesion is the primary culprit, which can stem from contaminants on the substrate, incompatibility between paint layers (e.g., applying a strong solvent-based topcoat over an insufficiently cured or weaker primer), or incorrect application leading to trapped solvents or insufficient film build. Ensuring every step, from initial cleaning to final curing, is executed correctly is paramount for marine paint durability and achieving long-lasting vessel protection. At JDmarine Paint Co., Ltd, we emphasize that quality coatings, like our extensive range, perform best when these fundamental principles are respected.

![[Image Placeholder: A split image – one side showing perfectly smooth, adhering marine paint, the other side showing paint peeling off a hull.] [Image Placeholder: A split image – one side showing perfectly smooth, adhering marine paint, the other side showing paint peeling off a hull.]](https://jdmarinepaint.com/wp-content/uploads/2025/06/a-split-image-one-side-showing-perfectly-smooth-2.png)

Understanding the ‘why’ behind each of these pillars will empower you to make informed decisions and take the necessary steps to keep your marine paint firmly in place, protecting your investment for years to come.

Why is Proper Surface Preparation Paramount to Prevent Marine Paint from Peeling?

Are you tempted to cut corners during the preparation phase to get to the painting faster? This is a significant gamble. Inadequate surface preparation is the leading cause of marine paint peeling. If the substrate isn’t perfectly clean, dry, and correctly profiled, even the most advanced marine coatings will struggle to achieve a tenacious bond. Contaminants like grease, oil, salt, old flaking paint, or even invisible moisture can create a barrier between the new paint and the surface, leading to delamination and peeling. Furthermore, a surface that isn’t properly abraded won’t provide the necessary mechanical "key" for the marine primer to grip effectively.

Proper surface preparation for marine paint is non-negotiable if you want to prevent marine paint from peeling. It’s the foundation upon which the entire coating system (marine) relies. The goal is to create a clean, dry, and uniformly abraded surface that promotes maximum paint adhesion. This involves several critical steps: cleaning to remove all soluble contaminants and loose debris; thorough sanding or, for tougher jobs, grit blasting to remove old, unsound paint and to create an anchor profile; and finally, a solvent wipe to eliminate any residual dust or grease before the first coat of primer is applied. For specific substrates, specialized treatments might be needed. For instance, when preparing galvanized steel, it’s crucial to ensure the surface is free from passivation treatments and correctly abraded; our JDH838 Primer for Galvanized Steel is designed for such applications, but only after proper prep. As detailed in our JDmarine Paint "Paint and its Maintenance Guide" ( p.47-59), neglecting any part of this stage significantly increases the risk of peeling paint (marine).

![[Image placeholder: Close-up shots of various surface preparation stages: cleaning, sanding a hull, a properly abraded surface ready for priming.] [Image placeholder: Close-up shots of various surface preparation stages: cleaning, sanding a hull, a properly abraded surface ready for priming.]](https://jdmarinepaint.com/wp-content/uploads/2025/06/微信图片_20250113092531-scaled.jpg)

Let’s break down the key elements of surface preparation that are crucial for adhesion:

Critical Surface Preparation Steps to Maximize Paint Adhesion and Prevent Peeling?

To truly prevent marine paint from peeling, each step in the surface preparation process must be meticulously carried out. This ensures the substrate (marine painting) is in optimal condition to receive the protective coatings for boats.

| Preparation Step | Detail & Purpose for Preventing Peeling | Recommended JDmarine Paint Practice/Products (where applicable) |

|---|---|---|

| 1. Thorough Cleaning | Removal of all visible and invisible contaminants like salt, dirt, grease, oil, wax, and marine growth. These act as bond-breakers. | Use appropriate marine detergents and degreasers. Pressure wash if possible. Refer to "Paint and its Maintenance Guide" section on cleaning. |

| 2. Removal of Old Paint | All loose, flaking, or unsound previous paint layers must be completely removed via scraping, sanding, or blasting. Feather edges of sound paint. | Ensures the new system is bonding to a stable surface, not one that will peel and take the new paint with it. |

| 3. Abrasion/Profiling | Creating a surface profile (roughness) appropriate for the chosen marine primer. This provides a mechanical key for the paint to grip. | For steel, Sa 2.5 grit blasting is ideal for high-performance systems like our JDH06-4 Epoxy Zinc-Rich Primer. For fiberglass or wood, use appropriate grit sandpaper. |

| 4. Dust Removal | All sanding or blasting dust must be meticulously removed. | Vacuum thoroughly, followed by a tack cloth or a solvent wipe using a clean, lint-free rag and the recommended thinner/solvent. |

| 5. Solvent Wipe | A final clean with a specific paint thinner (marine) or surface preparation solvent compatible with the primer to be applied. | For our epoxy primers like the versatile JDH815 Iron Red Epoxy Anti-Rust Primer, a wipe with Epoxy Thinner X-7 might be recommended by the TDS. Always check. |

| 6. Ensuring Dryness | The surface must be completely dry. Painting over moisture, even if not visible, will lead to blistering and peeling. Test for hidden moisture. | Allow ample drying time after washing. Check dew point and surface temperature to avoid condensation before and during application. |

Adhering to these steps, as recommended by JDmarine Paint technical guidelines, forms the most critical defense to prevent marine paint from peeling.

How Do Compatible Coating Systems Help Prevent Marine Paint from Peeling?

Ever applied a new topcoat only to see it react badly with the underlying layer, causing lifting or peeling? This nightmare scenario often stems from using incompatible products within your coating system (marine). A marine paint system is a multi-layer construction where each coat – primer, undercoat/build coat, and topcoat – must work in harmony. If the chemical composition or solvent strength of one layer is at odds with another, it can compromise the integrity of the entire system, leading to poor intercoat paint adhesion and eventual peeling paint (marine). For example, applying a strong two-part marine paint (2K) polyurethane over a single-part alkyd enamel that hasn’t fully cured and hardened can cause the solvent in the polyurethane to attack and lift the enamel.

A compatible coating system (marine) is crucial to prevent marine paint from peeling because it ensures strong chemical and mechanical bonds between successive layers. Marine primers are formulated to adhere tenaciously to the prepared substrate (marine painting) and provide a suitable surface for subsequent coats. Tie-coats or link coats are sometimes necessary to bridge incompatible layers. Topcoats must be compatible with the primer/undercoat to ensure they don’t cause issues like solvent attack, which weakens the underlying layers and leads to delamination. At JDmarine Paint , we design our products to work together as robust systems. For instance, our JDH263 Epoxy Link Coat or the JDH825 Solvent-Free Epoxy Link Coat are perfect for ensuring adhesion when applying our Antifouling series over an epoxy primed surface. Always follow the manufacturer’s recommendations for a complete, tested system to achieve optimal marine paint durability.

![[Image placeholder: Diagram illustrating a compatible marine paint system (Primer -> Intermediate Coat -> Topcoat) with arrows showing good adhesion between layers. Perhaps subtly feature JDmarine Paint product labels in the diagram.] [Image placeholder: Diagram illustrating a compatible marine paint system (Primer -> Intermediate Coat -> Topcoat) with arrows showing good adhesion between layers. Perhaps subtly feature JDmarine Paint product labels in the diagram.]](https://jdmarinepaint.com/wp-content/uploads/2025/06/a-diagram-illustrating-a-compatible-marine-paint-s-2.png)

Understanding the roles of different paint types and how they interact is key to building a peel-proof system.

Choosing Compatible Primers, Intermediates, and Topcoats to Prevent Peeling?

Selecting a cohesive set of products, from marine primers to marine topcoats, is fundamental in the fight to prevent marine paint from peeling. Each layer has a specific function and must be compatible with the next.

| Coating Layer | Role in Preventing Peeling & System Compatibility | JDmarine Paint System Examples |

|---|---|---|

| Marine Primers | Creates the primary bond with the prepared substrate (marine painting). Must offer excellent paint adhesion and be compatible with the chosen intermediate or topcoat. Provides corrosion prevention (marine). | For steel, JDH835 Aluminum Iron Epoxy Anti-Rust Paint provides a strong base. For difficult surfaces, JDH818 Low Surface Treatment Epoxy Primer offers enhanced adhesion. Traditional option: JDC53-31 Red Lead Alkyd Anti-Rust Paint. |

| Intermediate Coats / Tie-Coats | Builds film thickness for added protection, improves adhesion between primer and topcoat, or acts as a barrier/tie-coat between potentially incompatible layers (e.g., epoxy primer and vinyl antifouling). | JDH817 MIO Epoxy Anti-Rust (Intermediate) Paint builds excellent thickness and barrier properties. For linking epoxy primers to antifouling, JDH263 Epoxy Link Coat is ideal. |

| Marine Topcoats | Provides the final aesthetic finish and primary protection against UV, abrasion, and weather. Must be compatible with the underlying coats to avoid solvent attack or adhesion failure. | For superior gloss and UV resistance, JD918 Acrylic Polyurethane Hull Paint (yellowing resistant) or JDFT810 Fluorocarbon Topcoat are excellent choices over our epoxy systems. For a durable alkyd finish, consider JDC43-31 Alkyd Hull Paint. |

| Antifouling Paint (If applicable) | Prevents marine growth. Must be compatible with the underlying primer/tie-coat system. | Our JD753 Tin-Free Self-Polishing Antifouling Paint works well over our epoxy primer and link coat systems. For different needs, we offer JDL44-83 Asphalt Antifouling Paint (703). |

Always consult the JDmarine Paint technical data sheets (TDS) for each product to confirm intercoat compatibility, recoating windows, and specific system recommendations. Using a fully tested and recommended system from a single manufacturer like JDmarine Paint is the safest way to prevent marine paint from peeling due to incompatibility.

What Are the Correct Application Techniques to Prevent Marine Paint from Peeling?

You’ve done the meticulous prep and selected a compatible JDmarine Paint system, but if the paint isn’t applied correctly, could it still peel? Absolutely. Incorrect marine paint application techniques are a significant contributor to peeling paint (marine). Issues such as applying paint too thickly or too thinly, not allowing adequate drying time between coats, painting in unsuitable environmental conditions (too hot, too cold, too humid), or improper mixing of two-part marine paint (2K) products can all compromise adhesion and lead to premature failure. Trapped solvents from coats applied too heavily or too quickly can also cause blistering and subsequent peeling.

Correct marine paint application techniques are vital to prevent marine paint from peeling because they ensure each layer cures properly and achieves optimal adhesion to the previous coat and the substrate. This involves adhering to the manufacturer’s specifications for mixing ratios (especially crucial for two-part marine paint (2K) like our JDH819 Epoxy Zinc Phosphate Anti-Rust Primer which has a specific Part A to Part B ratio), recommended film thickness, application method (brush, roller, spray), and environmental conditions. For instance, many of our JDmarine Paint Epoxy series products, such as JDH816 Grey Epoxy Anti-Rust Primer, have specific pot life and recoat intervals that must be respected. Paying attention to these details ensures the coating system (marine) forms a cohesive, well-bonded film with excellent marine paint durability.

Let’s look at the key application factors influencing paint adhesion.

Key Application Factors for a Peel-Resistant Finish?

To prevent marine paint from peeling, adhering to best practices during the application phase is just as important as preparation and system selection. This ensures the chosen marine coatings, such as those from JDmarine Paint , perform to their full potential.

| Application Factor | Importance for Preventing Peeling | Best Practices & JDmarine Paint Considerations |

|---|---|---|

| Environmental Conditions | Temperature (air & substrate), humidity, and dew point significantly affect paint drying, curing, and adhesion. Painting outside recommended ranges can trap moisture or solvent. | Always consult the JDmarine Paint TDS for each product (e.g., JD908 Acrylic Polyurethane Topcoat will have optimal temperature ranges). Avoid painting if rain is imminent or if surface temperature is less than 3°C above dew point. |

| Proper Mixing | Especially critical for two-part marine paint (2K). Incorrect ratios or insufficient mixing leads to improper curing, soft spots, and poor adhesion. | For JDmarine Paint 2K products like our Epoxies or Polyurethanes, accurately measure and thoroughly mix components as per TDS. Observe induction times if specified. For instance, the mix ratio for JDH912 Epoxy Potable Water Tank Special Paint is critical for performance and safety. |

| Correct Film Thickness | Too thin: insufficient protection and potential for weak points. Too thick: can lead to solvent entrapment, wrinkling, sagging, and slow curing, all of which can cause peeling. | Use a wet film thickness (WFT) gauge during application to ensure the correct dry film thickness (DFT) is achieved as per the JDmarine Paint TDS. For example, our high-build JDH836 Solvent-Free Aluminum Iron Epoxy Anti-Rust Paint is designed for higher DFTs. |

| Recoating Intervals | Applying subsequent coats too soon can trap solvents. Waiting too long can require re-abrading the surface to ensure intercoat adhesion. | Strictly follow the minimum and maximum recoat times specified in the JDmarine Paint TDS for products like our JDB902 Acrylic Hull Paint or our quicker drying alkyds like JDC53-35 Aluminum Iron Alkyd Anti-Rust Paint. |

| Choice of Thinner | Using incorrect or too much paint thinner (marine) can affect curing, adhesion, and overall paint properties. | Only use the thinner recommended by JDmarine Paint for the specific product (e.g., Epoxy Thinner X-7 for epoxies, Polyurethane Thinner J-10 for polyurethanes) and only thin if necessary and within specified limits. |

| Application Method | Brush, roller, or spray gun. Ensure the chosen method is suitable for the paint and can achieve the required finish and film thickness. | JDmarine Paint products specify suitable application methods. Spraying often gives the most uniform film for topside paint like our Acrylic or Polyurethane series. |

By diligently following these application best practices for your chosen JDmarine Paint system, you significantly enhance the paint adhesion and drastically reduce the chances of encountering frustrating peeling paint (marine).

Conclusion

Preventing marine paint peeling relies on diligent surface prep, compatible JDmarine Paint systems, and correct application. Invest the effort upfront for lasting vessel protection.

![]()