Sailing to Success, Starting with the Right Coat: Expert Ship Surface Preparation & JDmarine Paint Superior Solutions for Dry-Docking Repairs

Opening:

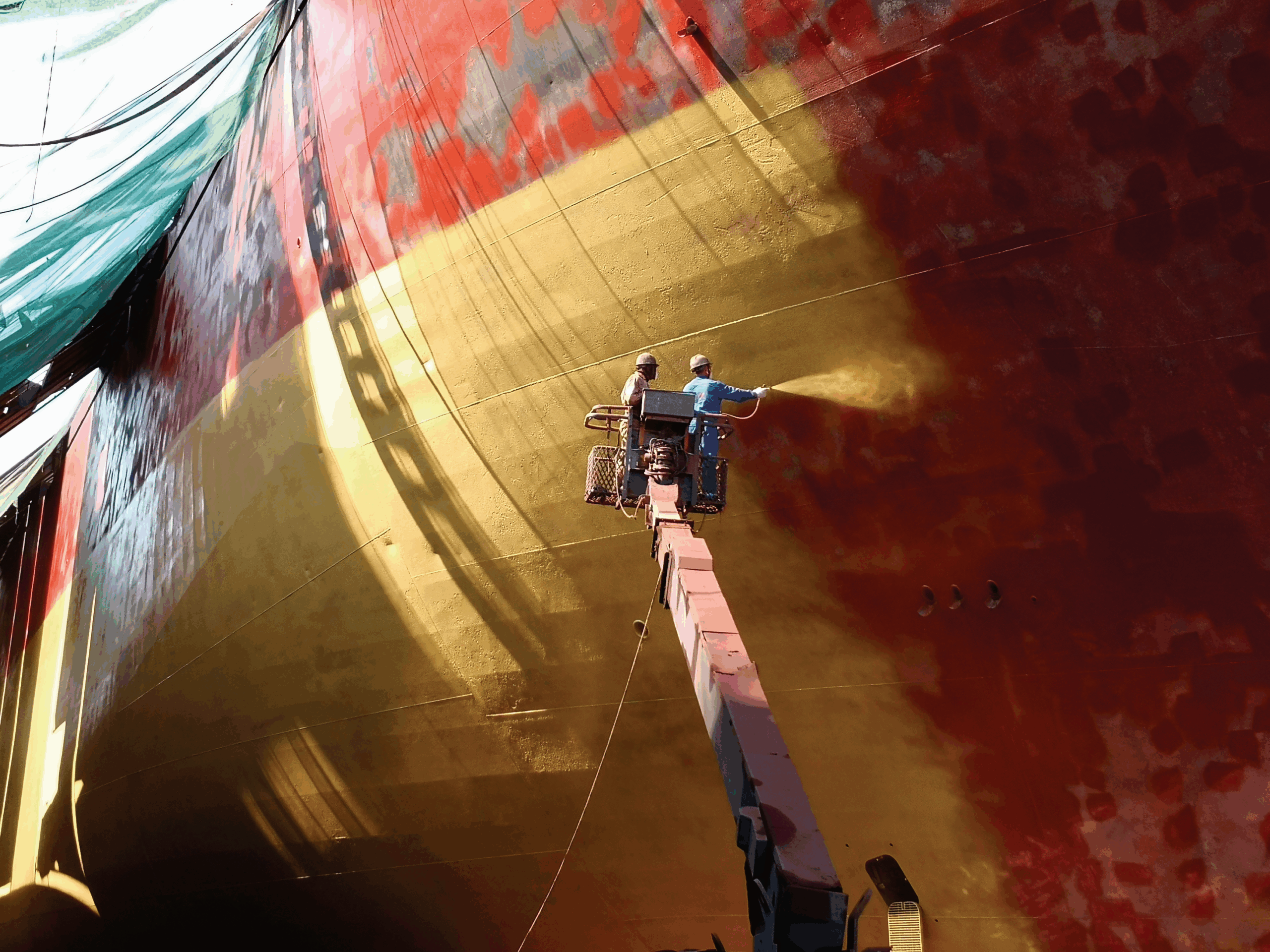

Vessels, the lifeblood of global trade, navigate the vast oceans, braving the elements. Yet, the harsh marine environment relentlessly challenges the integrity of a vessel’s "skin" – its protective coating system. A successful dry-docking repair isn’t just about aesthetics; it’s crucial for extending a ship’s lifespan and optimizing operational efficiency. Central to this is surface preparation before painting – the absolute cornerstone for achieving ultimate coating protection. As your trusted partner in marine protection, JDmarine deeply understands this criticality. Today, we unveil the "golden rules" of surface preparation during dry-docking and introduce our star products, designed to rejuvenate your vessel and ensure it’s ready for many more voyages!

Step 1: High-Pressure Fresh Water Washing – Establishing a Pure Foundation for Superior Coating Performance

Upon a vessel’s entry into dry dock, the primary task is a thorough "cleansing" of the hull. High-pressure fresh water washing effectively removes accumulated sea salts, grime, and other surface contaminants from prolonged voyages. This seemingly simple step is a critical prerequisite for ensuring our JDmarine coatings achieve optimal adhesion and deliver maximum protective power. Only a pristine substrate allows our coatings to bond seamlessly.

Step 2: Abrasive Blasting for De-rusting and "Skin" Rejuvenation – Preparing for a Robust "Coat of Armor"

Once salts are washed away, the true "deep clean" commences. Abrasive blasting (also known as shot blasting or colloquially "sandblasting") is typically employed. This is the most effective method for removing old paint, stubborn rust, and mill scale from the hull. The objective is to achieve an industry-recognized Sa2.5 surface cleanliness standard, creating the ideal roughness and cleanliness for subsequent coating application.

- JDmarine COATINGS Product Integration & Performance Spotlight:

After achieving an Sa2.5 grade through abrasive blasting, the steel surface is in optimal condition for coating. This is the perfect moment to apply our flagship product: JDH06-4 Epoxy Zinc-Rich Primer.

- JDH06-4 Epoxy Zinc-Rich Primer: This two-component primer is rich in high-purity zinc powder, providing exceptional cathodic protection to effectively prevent rust formation and spread. Its film dries quickly, offers super-strong adhesion, is impact and abrasion-resistant, and boasts excellent oil and solvent resistance. It forms the first robust "layer of armor" for the hull, perfectly compatible with subsequent JDmarine COATINGS coating systems.

Step 3: Strict Inspection and Acceptance – Ensuring Every Inch Meets the Standard

After abrasive blasting, it’s imperative not to rush to the next stage. The ship owner’s representative, the shipyard’s technical representative, or the marine paint technical representative (such as JDmarine COATINGS’ professional engineers) must meticulously inspect the treated surface. Only when the surface cleanliness and roughness fully meet the coating requirements (e.g., SSPC-SP10 or ISO 8501-1 Sa2.5 standard) can the next coating step proceed. JDmarine COATINGS firmly believes that meticulous inspection is an indispensable step in guaranteeing long-lasting coating performance.

Step 4: Localized Fine Treatment – Addressing "Problem Areas"

For small areas where abrasive blasting is not feasible or necessary (such as welds, corners, etc.), more flexible local treatment methods are required.

- Mechanical Grinding / Manual De-rusting:

- Manual Treatment: Detailed manual scraping using tools like rust hammers, scrapers, and wire brushes.

- Mechanical Treatment: Efficient rust removal using pneumatic tools such as pneumatic hammers, grinders, or rotating wire brushes.

- JDmarine COATINGS Product Integration & Performance Spotlight:

For these localized areas finely ground to St3 level (achieved with power wire brushes or sanding discs), or surfaces with slight flash rust after high-pressure water jetting, we highly recommend using JDH818 Low Surface Treatment Epoxy Primer.

- JDH818 Low Surface Treatment Epoxy Primer: This primer is specially designed for surfaces that are difficult to de-rust or have light rust. It offers excellent penetration and tolerance, providing strong adhesion and reliable anti-rust protection even on imperfectly prepared surfaces. Its high solids content and thick-film properties ensure that the protection in locally repaired areas is not compromised.

Step 5: Thorough Cleaning – Clearing the Way for Flawless Application

Whether after large-scale abrasive blasting or localized grinding, the de-rusting process leaves behind significant dust and debris. It is crucial to thoroughly blow the surface clean using oil-free compressed air. If conditions permit, an additional fresh water rinse followed by complete drying will yield even better results. This step ensures that JDmarine coatings are applied on the cleanest possible surface, preventing impurities from compromising coating adhesion and overall performance.

Step 6: Surface Roughening (for Two-Component Paints) – Enhancing "Grip" for an Unbreakable Bond

As you know, many high-performance marine paints offered by JDmarine COATINGS, such as our recommended JDH06-4 Epoxy Zinc-Rich Primer and JDH818 Low Surface Treatment Epoxy Primer, are two-component coatings. To achieve optimal adhesion, these types of coatings require the substrate surface to possess a certain degree of roughness. Appropriate roughness significantly increases the contact area between the coating and the steel, creating a powerful mechanical interlock – akin to a solid "foundation" for the coating, making it more secure, resistant to detachment, and ensuring long-term protection for the hull.

-

JDmarine COATINGS Product Connection & Performance Spotlight:

When you’ve selected JDmarine COATINGS’ epoxy primer series (such as JDH06-4, JDH818, or JDH838 Anti-Corrosive Primer for Galvanized Steel for galvanized surfaces), and plan to apply other types of topcoats or antifouling paints, ensuring flawless intercoat adhesion is paramount. For this, we recommend our JDH263 Epoxy Tie Coat or the more environmentally friendly JDH825 Solvent-Free Epoxy Tie Coat.

JDH263 Epoxy Tie Coat / JDH825 Solvent-Free Epoxy Tie Coat : These tie coats (also known as sealer coats or intermediate coats) effectively enhance the bond between different chemical types of coatings. They ensure the integrity and synergistic protective performance of the entire coating system and are particularly suitable for creating a strong link between epoxy primers and antifouling paints.

Conclusion:

As the saying goes, "Proper preparation prevents poor performance." In ship dry-docking, surface treatment is precisely the preparation that allows the "tool" of coating to perform at its best. Choosing professional treatment methods, coupled with JDmarine COATINGS high-performance marine paint products like our JDH series epoxy primers and tie coats, will undoubtedly provide your vessel with robust protection, empowering it to brave the elements and sail smoothly on all future voyages!

Interested in learning more about JDmarine COATINGS marine paint products and professional coating solutions? We welcome you to contact us at any time!

![]()