Marine Paint Showdown: Durability, ROI & Asset Protection for Business Owners

In the relentless world of marine operations, your vessels aren’t just assets – they’re your livelihood. From bustling cargo ships to vital workboats and elegant yachts, the harsh marine environment constantly challenges their protective barriers. Choosing the right marine paint isn’t a mere cosmetic choice; it’s a strategic investment that directly impacts your fleet’s longevity, operational efficiency, and, crucially, your bottom line. As a business owner, you face a pivotal decision: opt for the simpler, often cheaper, single-component paints, or invest in the formidable protection of two-component systems?

Understanding the critical nuances of single-component vs. two-component marine paint durability is absolutely essential for making an informed choice that will safeguard your assets for years to come.

This comprehensive guide will dissect the characteristics, benefits, and trade-offs of each paint type, with a laser focus on total cost of ownership (TCO), return on investment (ROI), and robust asset protection. By the end, you’ll clearly see how your marine coating decision influences everything from maintenance schedules to vessel value, ensuring your fleet remains seaworthy, profitable, and ready for whatever the sea throws its way.

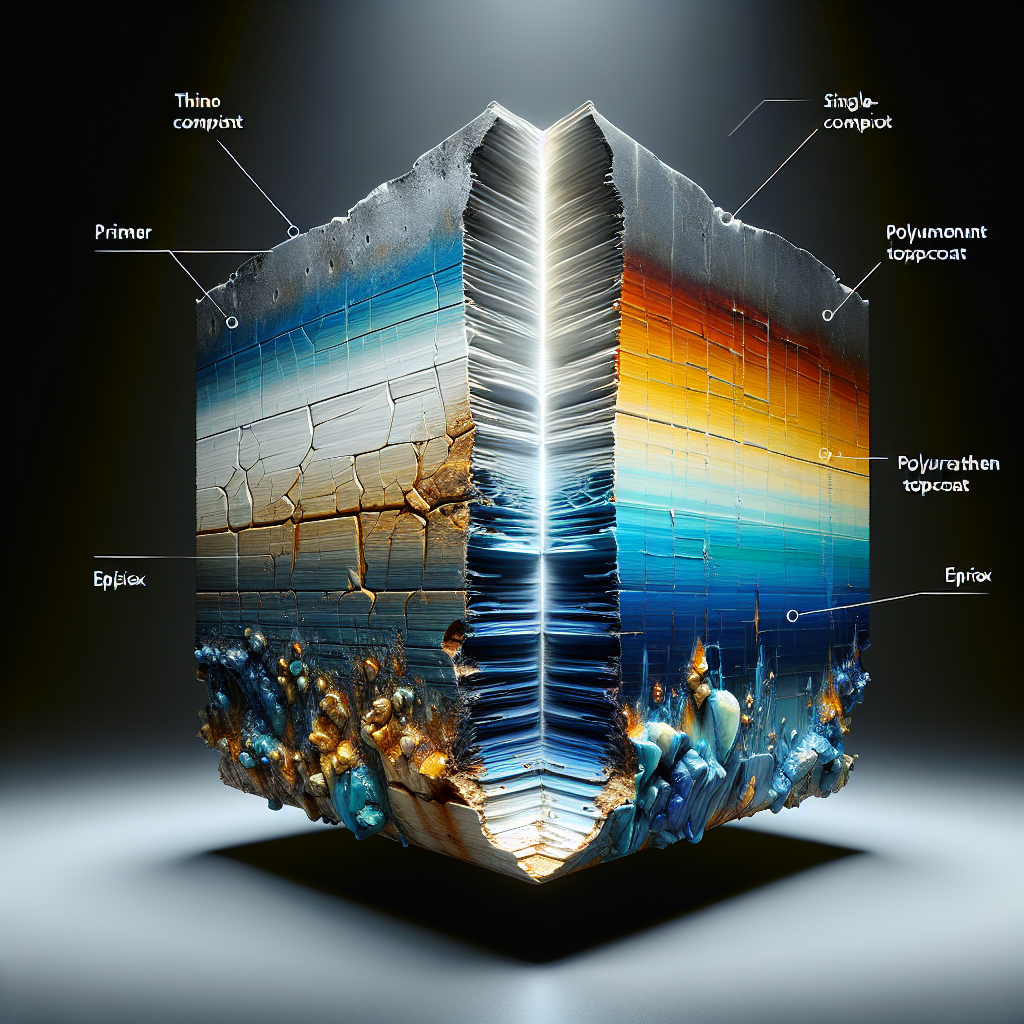

The Foundation of Protection: Understanding Marine Paint Types

Before we dive deep into the specifics, it’s vital to grasp the fundamental differences in how single-component and two-component marine paints are formulated and how they cure. This distinction is the bedrock of their performance characteristics.

Marine paints are engineered to conquer a unique gauntlet of challenges: constant immersion in corrosive saltwater, relentless UV radiation, abrasive docking and debris, and the persistent growth of marine organisms. A thorough marine coating comparison reveals that while both paint types offer protection, their levels of resilience vary dramatically.

Single-Component Marine Paints: Simplicity with Caveats

Often called “one-part” or “air-drying” paints, single-component marine paints cure through solvent evaporation or by reacting with atmospheric moisture. Their typically simpler chemical composition makes them incredibly user-friendly – a definite appeal for many.

Advantages of Single-Component Systems:

- Ease of Application: No mixing required! This translates directly into excellent application efficiency and potentially significant labor cost savings marine paint application, as the process is less complex and demands less specialized equipment or training.

- Lower Initial Cost: The per-gallon price of single-component paints is generally lower, making them attractive for tighter upfront budgets.

- Flexible Recoating: Minor repairs are often simpler, as these paints can frequently be touched up or recoated without extensive surface preparation.

- Versatility: Many are suitable for above-waterline areas or less demanding applications on recreational vessels.

Limitations of Single-Component Systems:

While convenient, single-component paints typically offer less robust protection. Their overall durability is generally lower compared to their two-component counterparts, particularly concerning:

- Abrasion Resistance: They are more susceptible to scratching and impact damage.

- Chemical Resistance: Less resistant to fuels, oils, and other common marine chemicals.

- UV Stability: Some may chalk or fade over time, especially in direct sunlight, impacting aesthetics and requiring more frequent reapplication cycles.

- Marine Paint Lifespan: You can expect shorter paint reapplication cycles, which, while seemingly minor, accumulate into substantial labor and dry-docking costs over the long haul.

For example, our JDC43-31 Alkyd Hull Paint is an excellent single-component option for certain applications, offering good general protection for above-waterline areas where extreme durability isn’t the primary concern. Similarly, JDC42-31 Alkyd Boottopping Paint provides reliable performance for specific waterline needs.

Two-Component Marine Paints: Unmatched Performance and Protection

Two-component marine paints, or “two-part” systems, consist of a base (resin) and a separate hardener (catalyst) mixed just before application. This mixture triggers a powerful chemical reaction, creating a tough, cross-linked film that delivers superior performance. Common types include epoxy and polyurethane marine paints, known for their incredible resilience.

Advantages of Two-Component Systems:

- Superior Durability: This is where two-component paints truly excel. Their cross-linked molecular structure provides exceptional hardness, abrasion resistance, and impact strength. This significantly extends the marine paint lifespan and overall vessel asset longevity.

- Excellent Corrosion Prevention Marine: Epoxy systems, in particular, are celebrated for their outstanding adhesion and impermeability, forming a formidable barrier against water and corrosive agents. This makes them ideal for robust hull protection strategies and demanding underwater applications. Our JDH817 MIO Epoxy Anti-Rust Tie Coat and JDH263 Epoxy Tie Coat exemplify this superior corrosion resistance. For a solvent-free option, consider our JDH825 Solvent-Free Epoxy Tie Coat.

- Enhanced UV Stability Marine Coatings: While epoxies can chalk with prolonged UV exposure, they are often overcoated with polyurethane topcoats. The distinct polyurethane marine paint advantages include exceptional UV stability, gloss retention, and color fastness, keeping your vessel looking pristine for longer. Products like our JD908 Acrylic Polyurethane Topcoat Non-Yellowing Resistant and JD918 Acrylic Polyurethane Hull Paint (Yellowing resistance) are specifically formulated for this. For extreme conditions, our JDFT810 Fluorocarbon Topcoat offers unparalleled UV and weather resistance.

- Chemical Resistance: Far more resistant to a wide range of chemicals, solvents, and fuel spills.

- Longer Reapplication Cycles: Due to their exceptional durability, two-component paints require far less frequent maintenance and reapplication, directly impacting your fleet maintenance optimization.

Limitations of Two-Component Systems:

- More Complex Application: Requires precise mixing ratios and has a limited pot life once mixed. This demands more skilled labor and careful planning.

- Higher Initial Cost: The per-gallon price is typically higher than single-component paints.

- Odor and Safety: Often have stronger odors and necessitate more stringent safety precautions during application.

Single-Component vs. Two-Component Marine Paint Durability: A Deep Dive into ROI and TCO

When evaluating single-component vs. two-component marine paint durability, savvy business owners must look beyond the initial purchase price. The real picture emerges when you consider the total cost of ownership (TCO). While two-component paints may have a higher upfront cost, their superior performance almost always translates into significant long-term savings and a dramatically better ROI.

The True Cost of Ownership (TCO)

The TCO isn’t just about the paint itself; it’s a comprehensive calculation that includes:

- Material Costs: The price of the paint.

- Labor Costs: Time spent on surface preparation, application, and reapplication.

- Dry-Docking Costs: Expenses linked to taking a vessel out of service for maintenance, including lost revenue, facility fees, and associated services.

- Repair Costs: Expenses incurred due to premature coating failure, which can lead to corrosion or damage to the hull.

- Fuel Efficiency: A smooth, well-protected hull contributes to better hydrodynamics and fuel efficiency, especially when paired with effective anti-fouling solutions.

A robust marine coating comparison reveals a stark truth: single-component paints, because of their shorter lifespan and lower durability, often necessitate more frequent paint reapplication cycles. This means any initial labor cost savings marine paint application provides are quickly overshadowed by more frequent dry-docking and material purchases. These repeated service interruptions can lead to substantial lost revenue and inflated dry-docking costs, swiftly eroding any perceived upfront savings.

Conversely, investing in high-quality two-component systems, like our epoxy and polyurethane offerings, provides superior corrosion prevention marine and extends the marine paint lifespan significantly. This crucial reduction in major maintenance frequency leads to:

- Fewer Dry-Dockings: Minimizing costly downtime and maximizing vessel operational time.

- Reduced Labor: Less frequent preparation and application work over the long run.

- Enhanced Asset Value: A well-protected hull maintains its structural integrity and aesthetic appeal, contributing to higher resale value and impressive vessel asset longevity.

Maximizing ROI with Strategic Paint Selection

Your ROI from marine paint becomes crystal clear once these long-term benefits are factored in.

- Epoxy marine paint benefits for primers and undercoats create an impenetrable shield against corrosion, preventing costly structural damage that could lead to expensive repairs or even premature decommissioning.

- Polyurethane marine paint advantages as topcoats ensure excellent UV stability marine coatings and abrasion resistance, maintaining the vessel’s pristine appearance and guarding against physical wear and tear. This is paramount for fleet aesthetics and professional image.

For vessels operating in challenging conditions, choosing higher durability is a no-brainer. The harshness of the marine environment demands coatings that can withstand constant abuse. This is absolutely critical for effective hull protection strategies and ensuring continuous, uninterrupted operation.

When it comes to anti-fouling effectiveness, while anti-fouling paints are a distinct category, their performance is inherently tied to the quality of the underlying primer and topcoat system. A durable, well-adhered two-component system provides the ideal foundation for anti-fouling paints to perform optimally, preventing premature detachment and enhancing their effectiveness against barnacles, algae, and other marine growth. This further contributes to improved fuel efficiency and reduced cleaning costs – a win-win for your bottom line.

Making the Right Choice: Factors to Consider

Selecting the ideal marine paint system requires careful consideration of several key factors:

- Type of Vessel and Its Use:

- Commercial Vessels (Cargo, Fishing, Workboats): These demand the highest levels of durability, corrosion prevention marine, and abrasion resistance due to constant operation and exposure to extreme conditions. Two-component systems are almost always the optimal choice here for superior fleet maintenance optimization and maximizing uptime.

- Recreational Vessels (Yachts, Leisure Boats): While sometimes utilizing single-component paints for less critical areas, these still benefit immensely from two-component systems for hulls and high-wear areas.

- Operating Environment:

- Saltwater vs. Freshwater: Saltwater is far more corrosive, mandating superior protection.

- Climate: Areas with intense UV radiation require topcoats with excellent UV stability marine coatings.

- Mooring Conditions: High-traffic docks or areas with abrasive debris require higher abrasion resistance.

- Budget (Initial vs. Long-Term):

- If short-term costs are the absolute priority, single-component might seem attractive, but be prepared for a higher long-term TCO.

- For true long-term savings and ROI, investing in two-component paints upfront will pay significant dividends.

- Application Expertise and Resources:

- Do you have skilled labor and the necessary equipment for the precise mixing and application of two-component paints? If not, factor in the cost of professional application.

- Specific Protection Needs:

- Is anti-fouling effectiveness paramount? Ensure your chosen system is compatible with the best anti-fouling coatings.

- Is heavy abrasion resistance needed for high-impact areas?

- Is UV stability marine coatings a priority for aesthetic appeal and long-term color retention?

By thoroughly assessing these critical factors, business owners can tailor their marine paint strategy to meet their specific operational demands and financial objectives with confidence.

Conclusion

The decision between single-component and two-component marine paint systems is a truly pivotal one for any business owner in the marine industry. While single-component paints offer simplicity and lower initial costs, their inherent limitations in durability, marine paint lifespan, and overall resistance often lead to a significantly higher total cost of ownership (TCO) through increased maintenance, more frequent paint reapplication cycles, and substantial dry-docking costs.

Conversely, investing in high-performance two-component systems – leveraging epoxy marine paint benefits for superior adhesion and corrosion prevention marine, and polyurethane marine paint advantages for exceptional UV stability marine coatings and abrasion resistance – offers unparalleled long-term asset protection and a dramatically higher ROI. These robust coatings contribute to extended vessel asset longevity, optimized fleet maintenance optimization, and ultimately, a more profitable and reliable operation.

At JD Marine Paint, we deeply understand the critical balance between performance and value. Our comprehensive range of marine coatings, from our exceptionally durable JDH series epoxies to our high-performance JD900 series polyurethanes and JDFT fluorocarbons, is meticulously designed to meet the diverse and demanding needs of the marine industry. Don’t compromise on the protection of your most valuable assets. Choose wisely, choose for the long term, and ensure your vessels are equipped to thrive in the harshest marine environments.

![]()