Marine biofouling severely impacts operational efficiency, driving up fuel costs and maintenance downtime. Choosing the right fouling control coating technology is a critical decision to protect your assets and boost profitability.

The optimal fouling control coating solution depends on your specific business needs, including vessel type, operational profile, budget constraints, and increasingly strict environmental regulations. The main technologies fall into three categories: Self-Polishing Coatings (SPCs), Fouling Release Coatings (FRCs), and Hard Antifouling Paints. Self-Polishing Coatings provide steady protection for 3-5 years by controllably releasing biocides through hydrolysis, making them ideal for balancing fuel efficiency and maintenance costs on active vessels. Fouling Release Coatings offer a biocide-free, physical solution; their ultra-slick, low-energy surface prevents marine life from attaching firmly, making them perfect for high-speed vessels seeking maximum environmental credentials and fuel economy, with a service life of 5-10 years. Hard Antifouling Paints, an economical and traditional choice, prevent fouling by leaching biocides from a hard paint film, making them particularly suitable for low-speed or infrequently moved vessels and fixed marine structures.

![[Image Placeholder]**Image Title:** Biofouling: The Visible Cost and the Unseen Threat**Image Description:** A stark comparison between a smooth, clean hull and one covered in marine growth, vividly illustrating the importance of effective antifouling coatings for maintaining vessel performance.**Prompt:** A split-screen, photorealistic image comparing a ship's hull below the waterline. The left side is clean, sleek, and freshly painted with a high-performance marine coating. The right side is heavily fouled with barnacles, algae, and marine growth. The water is clear, highlighting the stark contrast in surface condition and hydrodynamic efficiency. [Image Placeholder]**Image Title:** Biofouling: The Visible Cost and the Unseen Threat**Image Description:** A stark comparison between a smooth, clean hull and one covered in marine growth, vividly illustrating the importance of effective antifouling coatings for maintaining vessel performance.**Prompt:** A split-screen, photorealistic image comparing a ship's hull below the waterline. The left side is clean, sleek, and freshly painted with a high-performance marine coating. The right side is heavily fouled with barnacles, algae, and marine growth. The water is clear, highlighting the stark contrast in surface condition and hydrodynamic efficiency.](https://jdmarinepaint.com/wp-content/uploads/2025/10/generated-image-october-15-2025-11_40am.webp)

This comprehensive business comparison guide will break down these three leading technologies. We’ll cut through the complex jargon and focus on the three core business criteria—Cost, Application Scenarios, and Performance Lifespan—to help you make the most strategic decision for optimizing your vessel’s performance and cost-efficiency.

Are Self-Polishing Coatings (SPCs) the Dynamic Solution for Your Fleet?

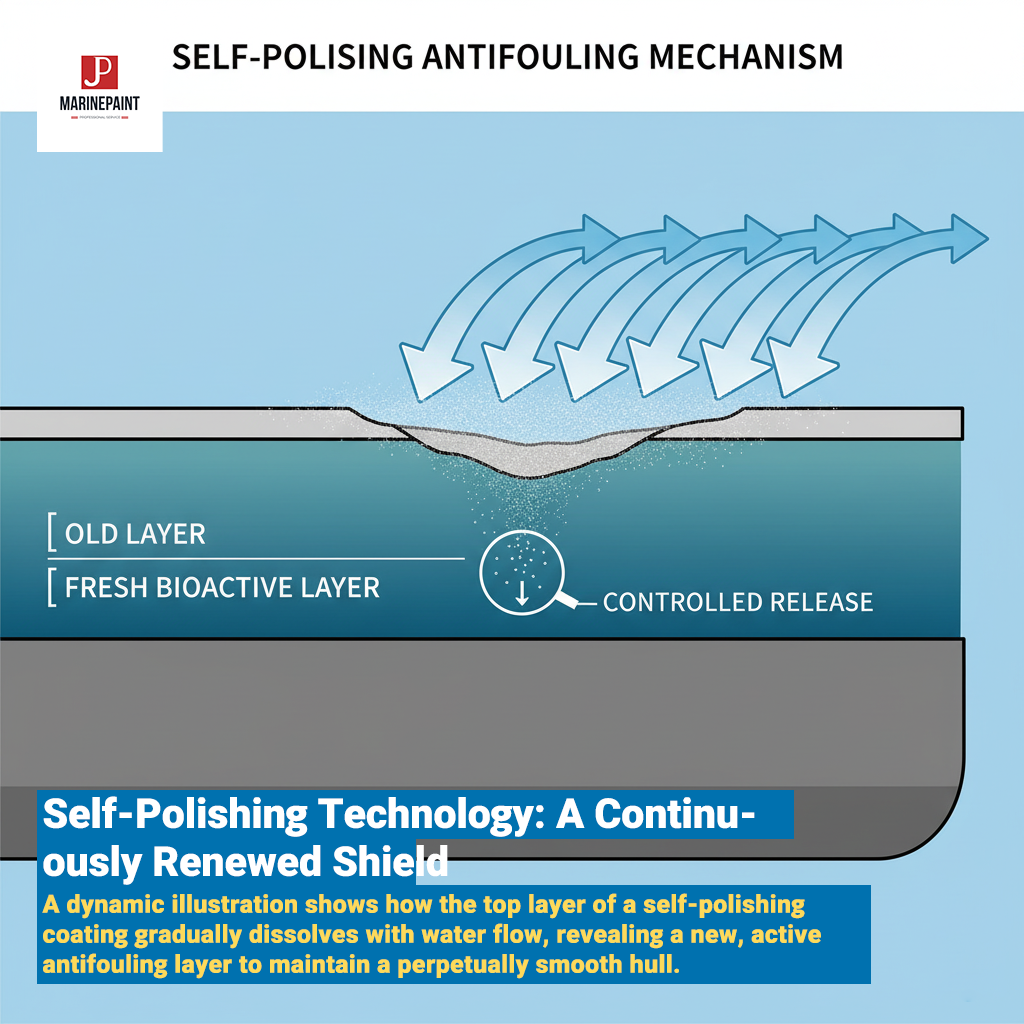

In vessel operations, you need consistent and reliable antifouling performance to avoid frequent dry-docking and recoating. Unpredictable protection leads to fluctuating fuel consumption and disrupted maintenance schedules, directly impacting your bottom line. While the effectiveness of traditional antifouling paints diminishes over time, Self-Polishing Coatings (SPCs) offer a dynamic solution by continuously renewing their surface to keep the hull smooth and clean for years. This active protection mechanism delivers significant long-term economic benefits, making it an ideal choice for owners and operators seeking a perfect balance between performance and cost.

The core technology of SPCs lies in their unique chemical hydrolysis or ion-exchange mechanism. As the vessel moves through the water, the coating’s surface layer slowly dissolves (or "polishes") at a precisely calculated rate. This process constantly exposes a fresh, new surface containing active biocides. This dynamic renewal ensures that the antifouling performance remains stable and effective throughout its entire service life, avoiding the sharp performance drop-off seen in older paint types. At JDmarine, we offer advanced tin-free options like our JD753 Tin-Free Self-Polishing Antifouling Paint and our JD853 Tin-Free Self-Polishing Antifouling Paint, which provides approximately three years of long-lasting protection. These products are specifically designed for ocean-going vessels in tropical and subtropical waters and represent high-performance, environmentally responsible choices.

Cost, Application, and Lifespan: A Full Analysis of SPCs

To help you make a comprehensive assessment, we will analyze self-polishing coatings from the three perspectives most critical to any business decision.

Cost Comparison: Balancing Upfront Investment with Long-Term Value

The initial investment for SPCs is typically in the moderate-to-high range. However, their true economic advantage is realized in long-term operation. By maintaining a smooth hull surface, SPCs significantly reduce fuel consumption, which constitutes the largest savings in their total cost of ownership. Furthermore, a long effective lifespan of 3-5 years translates to extended dry-docking intervals, minimizing downtime and related manual cleaning costs. Choosing modern SPCs that comply with International Maritime Organization (IMO) regulations is also a wise investment in ensuring global operational compliance and avoiding potential fines.

Ideal Application Scenarios

The "polishing" mechanism of SPCs relies on water flow, making them perform best in specific scenarios:

- High-Speed Vessels: For vessels with consistent movement and steady speeds, water flow effectively activates the polishing process, making SPCs an ideal choice.

- Low-Speed or Infrequently Operated Vessels: Even at lower speeds or when stationary, modern SPCs can still provide effective protection through slow hydrolysis, though the polishing rate may be less than on high-speed vessels.

- Fixed Installations: SPCs are generally not recommended for static structures like offshore platforms or buoys, as they lack the consistent water flow required to activate the polishing mechanism.

Performance Lifespan Expectation

The performance lifespan of a self-polishing coating is typically between 3 and 5 years. The exact duration depends on the product formulation (for instance, our JD853 is designed to provide around 3 years of protection), vessel activity, speed, and the marine environment (e.g., water temperature, salinity, and severity of biofouling). The greatest advantage of SPCs is their performance consistency—the controlled release rate of the biocide ensures uniform protection throughout the entire service interval.

| Decision Factor | Self-Polishing Coating (SPC) Evaluation |

|---|---|

| Overall Cost | Moderate to high initial cost, but excellent long-term ROI through fuel and maintenance savings. |

| Best Application | Continuously operating commercial vessels, especially medium- to high-speed fleets. |

| Performance Lifespan | 3-5 years of consistent and reliable performance. |

Are Fouling-Release Coatings (FRCs) the Ultimate Choice for ROI and Eco-Compliance?

As global environmental regulations tighten, traditional biocides are facing increased scrutiny. Are you searching for a cutting-edge solution that meets the strictest environmental standards while dramatically improving operational efficiency? The risk of non-compliance can lead to hefty fines and operational restrictions, while fuel costs remain a dominant expenditure. Fouling Release Coatings (FRCs) offer a revolutionary, biocide-free strategy. By creating an ultra-slick physical surface that prevents attachment, they align your business with sustainability goals and deliver substantial fuel savings by reducing hull drag—a true win-win for environmental responsibility and commercial profitability.

The working principle of FRCs is purely physical, not chemical. These coatings, typically silicone-based, have extremely low surface energy, which makes the paint film exceptionally smooth—much like a non-stick frying pan. This slippery characteristic makes it incredibly difficult for the spores and larvae of marine organisms like barnacles and algae to gain a firm hold. For any organisms that do manage to attach weakly, the hydrodynamic forces generated when the vessel reaches a certain speed (usually 15+ knots) easily wash them away, creating a "self-cleaning" effect. This is a fouling control method that is completely harmless to the marine ecosystem and represents the future of high-performance hull coatings and a leading technology for Hull performance optimization for shipping

Cost, Application, and Lifespan: A Full Analysis of FRCs

As a high-tech solution, FRCs come with unique cost and application considerations, requiring decision-makers to weigh their significant long-term value.

Cost Comparison: The High-Tech, High-Ticket Investment

The initial material and application costs for FRCs are the highest among all antifouling technologies. This is due not only to their complex chemical formulation but also to the extremely strict requirements for surface preparation and application—any imperfection can compromise performance. However, the long-term returns are equally impressive. Thanks to their dramatic drag-reducing effects, FRCs can deliver very significant fuel savings. Moreover, their ultra-long service life (5-10 years or more) and minimal maintenance needs (virtually no cleaning required, no biocide reapplication concerns) mean that over the entire lifecycle, the total cost of ownership can be lower than other technologies.

The Best Application Scenarios for FRCs

The performance of an FRC is closely tied to a vessel’s operational profile:

- High-Speed Vessels: The "self-cleaning" effect is most potent on vessels that consistently operate above 15 knots, making FRCs the perfect choice for high-speed fleets like container ships, cruise liners, and LNG carriers.

- Low-Speed or Infrequently Operated Vessels: For vessels with slower speeds or long idle periods, FRCs are less effective because they lack sufficient hydrodynamic force to wash off fouling. They are not recommended for this use.

- Fixed Installations: Similarly, due to the lack of water flow, FRCs are unsuitable for static marine structures.

Performance Lifespan Expectation

This is one of the most compelling advantages of FRCs. When applied correctly and kept free of physical damage, their performance lifespan is commonly 5+ years, with many premium products lasting up to 10 years. Their durability is exceptionally high, offering shipowners the longest possible dry-docking intervals and the most stable long-term performance outlook.

| Decision Factor | Fouling-Release Coating (FRC) Evaluation |

|---|---|

| Overall Cost | Highest initial investment, but potentially the lowest lifecycle cost due to extreme fuel savings and ultra-long service life. |

| Best Application | High-speed (>15 knots), high-activity vessels, and operators focused on a premium environmental reputation. |

| Performance Lifespan | 5-10+ years, making it the longest-lasting antifouling solution available. |

Are Hard Antifouling Paints Your Most Practical and Economical Choice?

For many operators, controlling upfront procurement costs is the primary objective, especially when budgets are tight or a vessel’s operational profile is unique. Traditional antifouling paints are market-proven, technologically mature, and widely used. But do you worry that a lower initial investment might lead to higher long-term maintenance costs, such as more frequent dry-dockings, increased fuel burn, and potential environmental compliance pressures? Hard Antifouling Paints offer a direct, effective, and economical solution that remains an indispensable choice in specific application scenarios. They provide reliable protection for slower-moving or long-idling vessels, ensuring asset integrity under static conditions.

The antifouling mechanism of hard paints is known as "contact leaching." Biocides (like cuprous oxide) are embedded within a hard, porous, and insoluble resin matrix. When the coating is immersed in seawater, these biocides slowly leach out from the micropores, creating a toxic micro-environment on the hull’s surface that inhibits the settlement of marine organisms. Over time, the biocides in the surface layer are depleted, and the antifouling effect gradually weakens. In the JDmarine product line, traditional chlorinated rubber options like JD713 Chlorinated Rubber Antifouling Paint and JD744 Chlorinated Rubber Antifouling Paint, as well as our budget-friendly JDL44-83 Bituminous Antifouling Paint, fall into this category, providing customers with cost-effective, traditional fouling control.

Cost, Application, and Lifespan: A Full Analysis of Hard Antifouling Paints

As a mature technology, the characteristics of hard antifouling paint are very distinct. Understanding its pros and cons is key to making the right choice.

Cost Comparison: The Lowest Initial Outlay

The initial purchase and application costs of hard antifouling paints are generally the lowest of any fouling control technology, making them the go-to choice for many budget-sensitive projects. However, decision-makers must consider their higher long-term maintenance costs. As the biocides are depleted, the paint film becomes rough, which can increase hull drag and, consequently, fuel consumption. More significantly, their shorter effective period means more frequent dry-docking for recoating, which increases downtime and maintenance expenses. It is also crucial to ensure the biocides used comply with local regulations, such as the Environmental Protection Agency guidelines on marine vessels.

Application Scenarios for Hard Antifouling Paints

The performance of hard antifouling paint does not depend on vessel movement, which gives it a unique advantage in certain niches:

- Low-Speed or Infrequently Operated Vessels: It is the ideal choice for vessels that are slow-moving or spend significant time stationary, such as tugboats, barges, and fishing boats.

- Fixed Installations: It is the most common antifouling solution for offshore oil rigs, docks, buoys, and other underwater facilities, where it provides durable, static protection.

- Specialty Uses: Certain formulations are also suitable for mining equipment and general steel structures, offering both anti-corrosion and antifouling properties in specific industrial environments.

Performance Lifespan Expectation

The shorter lifespan of hard antifouling paint is its main drawback, typically lasting between 1 and 2 years. For example, the continuous release period for JD713 is about 6 months, while the designed effective period for JDL44-83 is within one year. After this period, its antifouling efficiency drops significantly, requiring timely maintenance and recoating to prevent heavy biofouling.

| Decision Factor | Hard Antifouling Paint Evaluation |

|---|---|

| Overall Cost | Lowest initial investment. However, long-term costs for fuel and frequent recoating can be higher. |

| Best Application | Low-speed or stationary vessels, fixed offshore installations, and budget-critical projects. |

| Performance Lifespan | 1-2 years, requiring regular maintenance and reapplication. |

Conclusion

Choosing the best fouling control coating is a strategic investment in your operational efficiency and profitability. The right decision depends on your vessel type, operational profile, budget, and environmental goals. Consulting with a technical expert is key to ensuring you get the best custom solution.

![]()