A Guide to Marine Coatings for Steel Corrosion Prevention

Facing the relentless attack of marine environments? Your steel assets are under constant threat from corrosion, a problem that costs the industry billions annually. The right protective coating is your first and best defense.

The most effective industrial marine coatings for steel corrosion prevention constitute a complete system, not just a single can of paint. The best approach involves a multi-layered strategy tailored to the specific needs of the asset. This typically starts with a high-performance primer, such as a zinc-rich or epoxy-based formula, to provide excellent adhesion and inhibit corrosion directly on the steel substrate. This is followed by one or more intermediate or build coats, usually epoxy-based, to create a robust barrier that is impermeable to water and corrosive salts. Finally, a durable topcoat, often a polyurethane, is applied to resist UV radiation, abrasion, and harsh weather conditions, while providing a long-lasting aesthetic finish. The ideal combination depends on the operational environment, such as the constantly submerged hull, the splash zone, or the atmospheric topside structures. A properly specified and applied system ensures long-term asset integrity, safety, and operational efficiency.

![[Image placeholder]**Image Title:** Before and After: The Power of Marine Coatings**Image Description:** A dramatic split-screen image showing one side of a ship's hull heavily corroded and rusted, contrasted with the other side which is smooth, clean, and protected by a fresh, high-performance marine coating.**Image Prompt:** A hyper-realistic, high-resolution split-view photograph. The left side shows a close-up of a steel ship hull with severe rust, flaking paint, and marine biofouling. The right side shows the same section of the hull perfectly restored with a glossy, brand-new navy blue industrial marine coating, reflecting the light. The division between the two sides is a sharp, clean vertical line. [Image placeholder]**Image Title:** Before and After: The Power of Marine Coatings**Image Description:** A dramatic split-screen image showing one side of a ship's hull heavily corroded and rusted, contrasted with the other side which is smooth, clean, and protected by a fresh, high-performance marine coating.**Image Prompt:** A hyper-realistic, high-resolution split-view photograph. The left side shows a close-up of a steel ship hull with severe rust, flaking paint, and marine biofouling. The right side shows the same section of the hull perfectly restored with a glossy, brand-new navy blue industrial marine coating, reflecting the light. The division between the two sides is a sharp, clean vertical line.](https://jdmarinepaint.com/wp-content/uploads/2025/09/a-dramatic-split-screen-image-showing-one-side-of-a-ships-hull-heavily.png)

To select the right coating system, we must first understand the enemy it is designed to fight. Let’s dive deeper into why steel corrosion is such a formidable challenge in the marine world.

Why is Steel Corrosion Prevention So Critical in Marine Applications?

Are you aware that the marine environment is one of the most corrosive natural environments on Earth? Steel structures like ships, offshore platforms, and port equipment are in a constant battle against elements that are determined to break them down. Ignoring the critical need for advanced corrosion control isn’t just a maintenance oversight; it can lead to catastrophic structural failures, crippling operational downtime, immense financial losses, and severe safety hazards for crew and cargo. Understanding the unique challenges of this environment is the first step toward implementing a truly effective protective strategy.

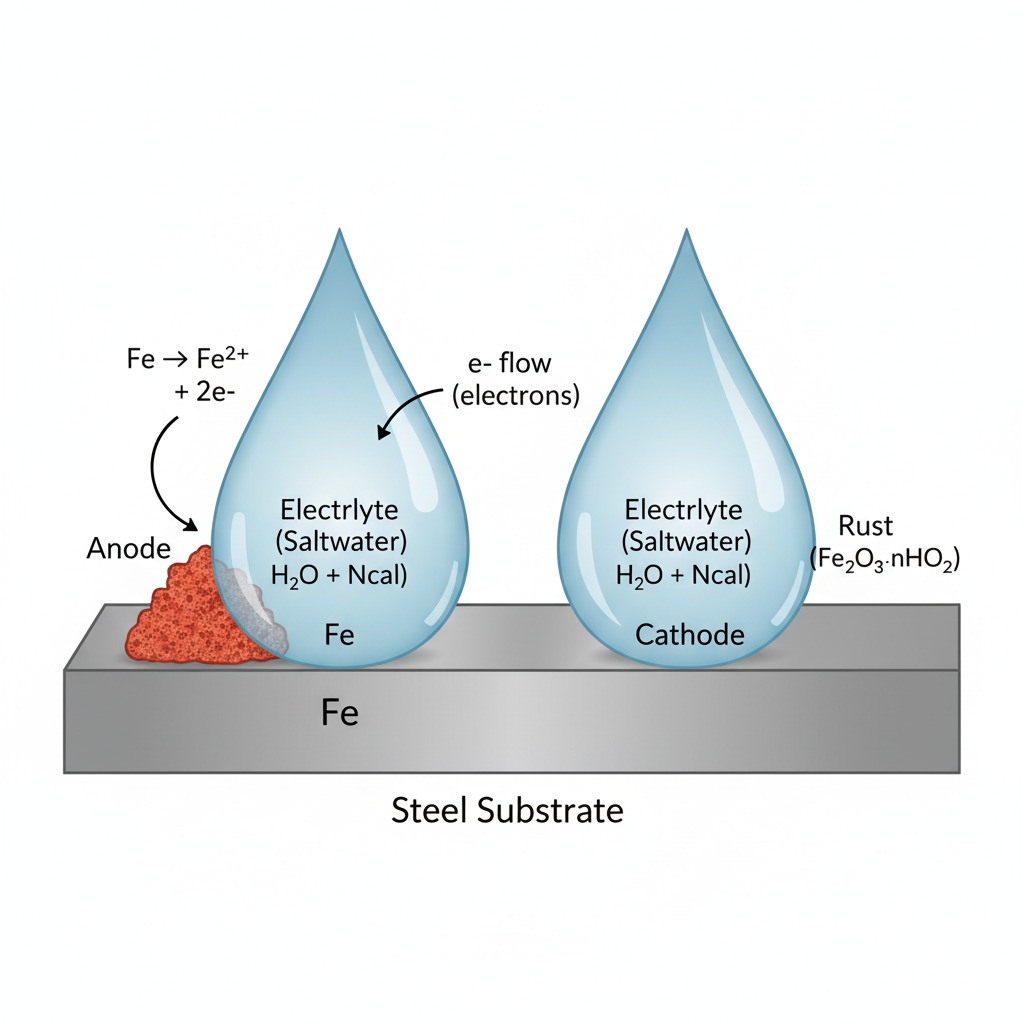

Steel corrosion prevention is paramount because marine environments present a perfect storm of corrosive forces. Unlike inland applications, marine steel is subjected to constant high humidity and direct contact with saltwater, which acts as a powerful electrolyte, dramatically accelerating the electrochemical process of rust formation. This saline environment, rich in chloride ions, aggressively attacks steel and undermines inferior coatings. Furthermore, relentless UV radiation from the sun degrades coating binders, causing them to chalk and lose their protective properties. Add to this the physical abrasion from wave action, cargo operations, and ice, and you have an environment where only the most robust protective coatings for steel can survive. A failure in the coating system exposes the steel substrate, creating a direct path to structural decay.

What are the Core Types of Industrial Marine Coatings for Steel Protection?

Ever wondered what makes up the multi-layer defense on a ship’s hull? A single type of paint is rarely enough to provide comprehensive protection. The harsh realities of the sea demand a systematic approach where each layer of coating has a specific job, from bonding to the steel to fighting off UV rays. Choosing the wrong type of coating for a specific area, like using a primer as a topcoat, can lead to premature failure of the entire system. Understanding the role of each primary coating type is crucial for designing a system that delivers durable and long-lasting corrosion control.

The selection of industrial marine coatings for steel corrosion prevention is based on a "system" philosophy, where different chemistries work together for maximum effect. Each coating type is chosen for its specific properties and its position within the coating layers. This ensures that the final system is perfectly optimized for the challenges of its specific service environment, whether it’s a ballast tank, a cargo hold, or the ship’s superstructure.

Epoxy Coatings: The Workhorse of Marine Corrosion Prevention

Epoxy coatings are two-component systems renowned for their exceptional adhesion to properly prepared steel, outstanding chemical resistance, and high durability. They form a tough, highly impermeable barrier that is the foundation of most high-performance marine corrosion protection systems. Their primary role is to serve as primers and intermediate coats, effectively shielding the steel substrate from direct contact with water and corrosive elements. Selecting a high-solids, high-build epoxy primer is crucial for creating a robust foundation for the entire coating system in demanding areas. However, it’s important to note that most traditional epoxies are susceptible to chalking and degradation from prolonged UV exposure, which is why they must be protected by a suitable topcoat in areas exposed to sunlight.

Polyurethane Coatings: The Durable Finishing Layer

Polyurethane coatings are the aesthetic and protective finish for the coating system. Applied as a topcoat over an epoxy primer and intermediate system, they provide a high-gloss, durable finish with excellent color and gloss retention. Their key benefit is superior resistance to UV radiation, which prevents the underlying epoxy from degrading. This makes them the ideal choice for topside structures, decks, and superstructures—any area that is visible and exposed to the elements. The result is not only long-lasting protection but also a finish that keeps a vessel looking pristine for years.

Zinc-Rich Primers: Sacrificial Protection for Steel

Zinc-rich primers offer a unique and powerful form of corrosion protection known as cathodic or "sacrificial" protection. These primers are formulated with a very high concentration of metallic zinc dust. Because zinc is more reactive than steel, it will corrode preferentially when the coating is scratched or damaged, "sacrificing" itself to protect the steel substrate underneath. This is a crucial defense mechanism that prevents corrosion from creeping under the coating film from a damaged area. These primers come in two main types: inorganic zinc silicates, which offer exceptional solvent and abrasion resistance, and organic epoxy zinc-rich primers, like our JDC53-31 Red Lead Alkyd Anti-Rust Paint, which provide excellent barrier properties and are often easier to apply.

The following table summarizes the primary roles of these key coating types:

| Coating Type | Primary Role | Key Benefits | Typical Application Area |

|---|---|---|---|

| Epoxy Coatings | Primer / Intermediate | Excellent Adhesion, Chemical Resistance, Barrier Protection | Ballast Tanks, Underwater Hulls |

| Polyurethane Coatings | Topcoat | UV Resistance, High Gloss, Color Retention, Abrasion Resistance | Decks, Superstructures, Topside |

| Zinc-Rich Primers | Sacrificial Primer | Cathodic Protection, Prevents Corrosion Creep | Hulls, Decks, Structural Steel |

What Key Properties Should You Demand from Your Marine Coating System?

When you’re evaluating a coating specification, do the technical data sheets seem overwhelming? Terms like "adhesion," "impermeability," and "flexibility" are more than just jargon; they are the measurable qualities that determine whether a coating system will succeed or fail. Specifying a system without understanding these core properties is like navigating without a compass—you might end up with a solution that isn’t fit for purpose, leading to premature failure and costly reapplications. To ensure the longevity and performance of your steel assets, it is essential to demand a coating system that excels in several critical areas.

Evaluating a high-performance marine grade paint requires looking beyond the price tag to its technical performance properties. A successful system must act as an integrated defense, where each property supports the others to create a resilient and long-lasting barrier. For example, excellent adhesion is useless if the coating is not also resistant to the chemicals it will be exposed to. This holistic view ensures that the chosen system can withstand the full spectrum of challenges present in the marine environment, from the chemical to the physical.

1. Superior Adhesion to Prepared Steel

Adhesion is the single most important property of any coating. It is the measure of how well the coating bonds to the steel substrate. Without tenacious adhesion, the entire system is compromised from the start. Any delamination or flaking creates an entry point for moisture and chlorides, leading to rapid under-film corrosion.

2. High Impermeability to Water and Chlorides

A primary function of any anti-corrosive paint for steel is to act as a barrier. The coating must have a densely cross-linked molecular structure that prevents water, oxygen, and corrosive ions (especially chlorides) from migrating through the film to reach the steel surface. This barrier property is a key function of epoxy mid-coats.

3. Excellent Chemical and Abrasion Resistance

Marine assets are exposed to a variety of harsh substances, including fuel, hydraulic oils, cleaning chemicals, and abrasive contact from cargo, equipment, or ice. The coating system, particularly in high-traffic areas like decks, must be robust enough to withstand this chemical and physical abuse without breaking down.

4. Flexibility and Impact Resistance

Steel structures, especially ships, are not rigid. They flex and bend with wave action and temperature changes. The coating system must be flexible enough to accommodate this movement without cracking. It must also be able to withstand impacts from equipment or debris without chipping or delaminating, which would create a breach in the protective barrier.

Conclusion

Effective industrial marine coatings for steel corrosion prevention rely on a complete system: meticulous surface preparation, the right coating chemistry for the environment, and precise application.

![]()