The Antifouling Paint Safety Bible: A Technical Guide

Antifouling paint is not just another coating; it’s a powerful chemical tool that is hazardous by design. Ignoring safety protocols can lead to serious health issues and environmental contamination.

Antifouling paint is a specialized, hazardous chemical coating designed to protect your vessel. The dual goal is to achieve this protection while ensuring the safety of the user and the marine environment [8]. This guide is a technical bible on the risks, safety procedures, and regulatory landscape surrounding antifouling systems. It provides the knowledge you need to handle these products with the respect they command, ensuring a clean hull doesn’t come at the cost of your health or the ecosystem.

As a technical consultant at JDmarine, my primary goal is to ensure our customers not only achieve superior hull protection but do so safely and responsibly. This guide is your foundation for that commitment.

What is the Chemical Warfare on Your Hull? A Scientific Look at Antifouling

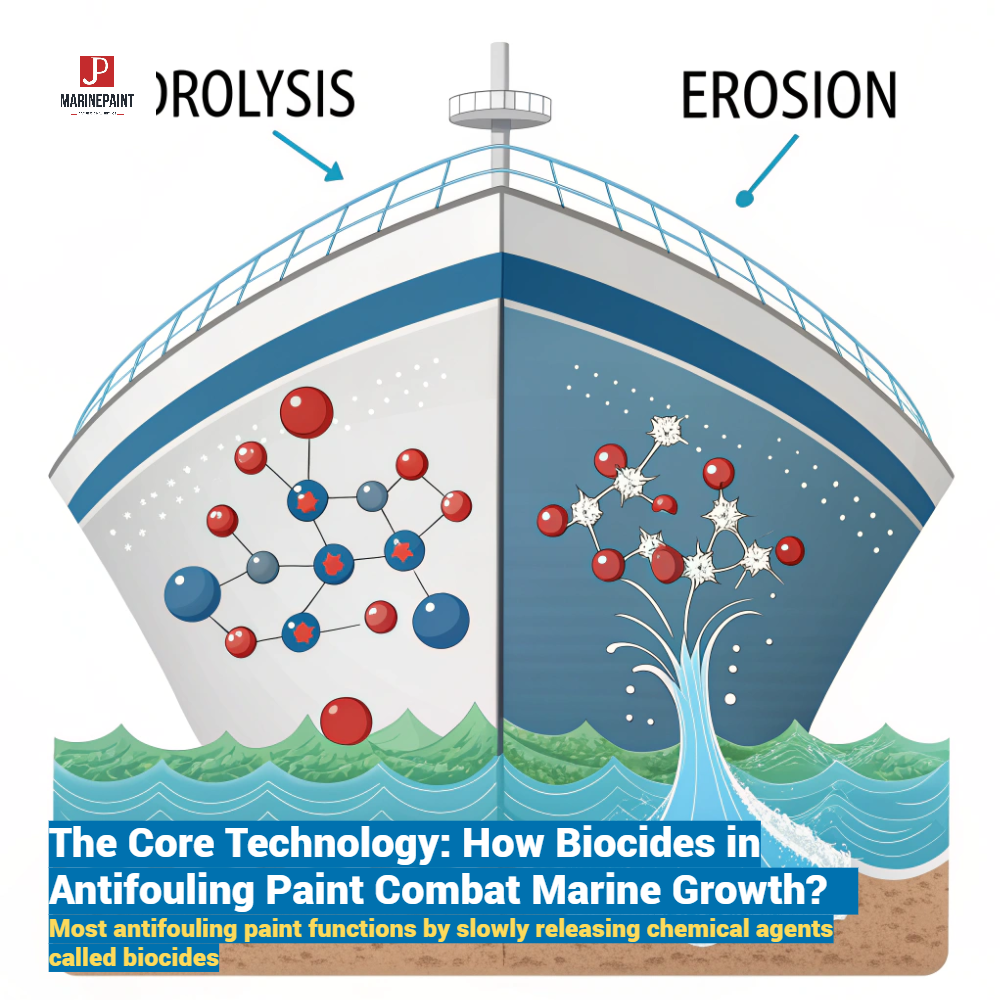

Have you ever considered that applying bottom paint is like initiating a controlled chemical battle on your hull? Without understanding the science, you might underestimate the product’s toxicity and its environmental impact. This lack of knowledge can lead to unsafe handling and improper disposal, contributing to the very environmental problems the industry is trying to solve. Knowing how these chemicals work—and what happens to them after they’ve done their job—is fundamental to responsible boat ownership.

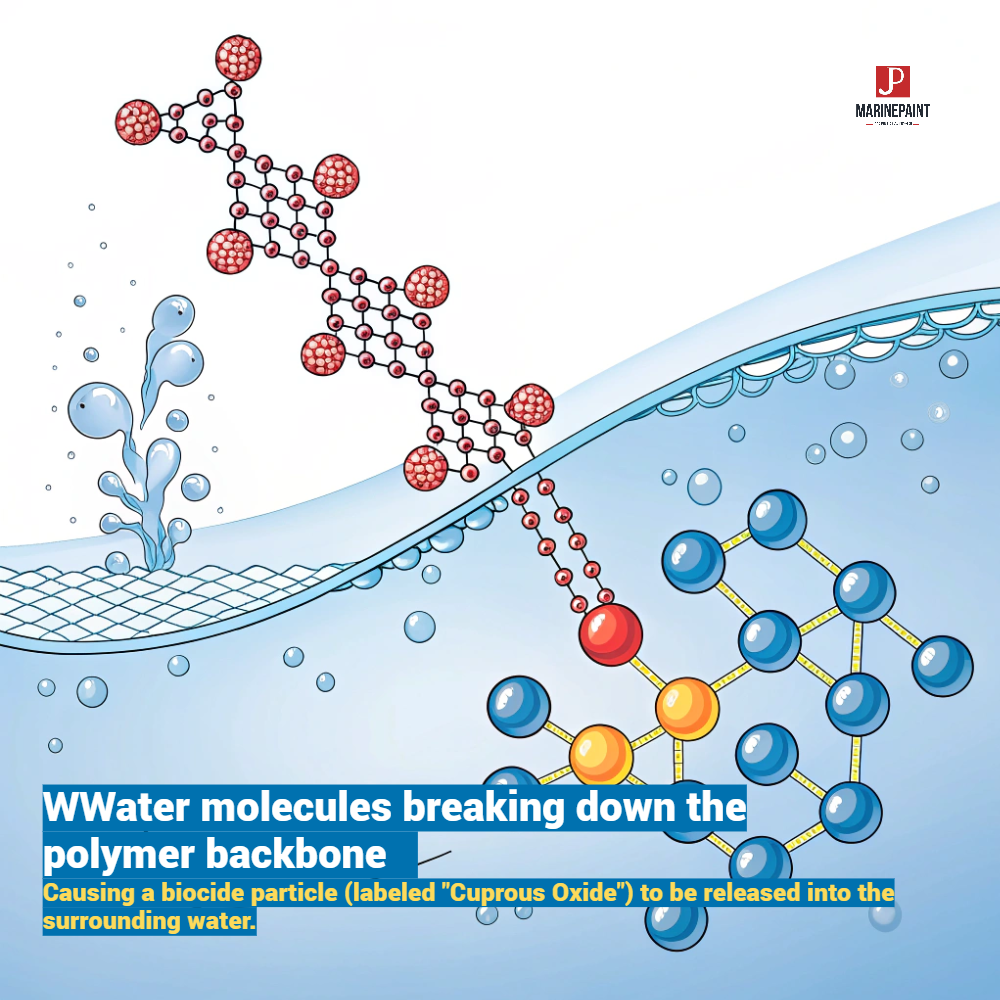

The effectiveness of antifouling paint lies in its biocides, chemical agents that deter marine growth. In modern paints, particularly self-polishing copolymers (SPCs), this process is highly controlled. For instance, our JD753 Tin-free self-polishing antifouling paint utilizes a self-polishing copolymer resin that erodes at a calculated rate, consistently releasing its biocide (in this case, cuprous oxide) to prevent fouling organisms from attaching [1, 16]. This controlled release is key to long-term effectiveness [2, 16]. However, the environmental fate of these biocides is a major concern. Once leached into the water, they can persist in sediment and bioaccumulate in the food chain. This was catastrophically demonstrated by Tributyltin (TBT), an incredibly effective but environmentally devastating biocide, now banned worldwide. The industry’s move to tin-free formulations reflects this critical lesson and a growing commitment to developing more environmentally friendly products [4].

The Health Risks: How Do You Protect Yourself from Toxic Exposure?

The very properties that make antifouling paint toxic to marine life also make it a significant health risk to humans [8]. The solvents and biocides can cause everything from skin irritation and respiratory problems to more severe long-term health issues if handled improperly. Believing a simple dust mask or a pair of gardening gloves is sufficient protection is a dangerous mistake that puts your health in jeopardy. Every time you open a can, stir the paint, or sand a hull, you are handling hazardous chemicals.

The primary routes of exposure are inhalation of toxic solvent vapors and paint dust, direct skin contact, and eye contact [8]. The golden rule for preventing harm is to use the correct Personal Protective Equipment (PPE) without fail [8]. This is not optional; it is a necessity. At a minimum, your PPE should include a respirator with the correct cartridges for organic vapors and particulates, chemical-resistant nitrile gloves, wrap-around safety goggles, and disposable coveralls to prevent skin contact. Furthermore, always work in a well-ventilated area to disperse fumes and minimize inhalation risk [8]. Following these safety precautions is the most important step you can take.

The Golden Rule: Personal Protective Equipment (PPE)

Handling antifouling paint safely is non-negotiable, and it begins with the right gear [8].

| PPE Item | Purpose | Why It’s Critical |

|---|---|---|

| Respirator | Inhalation Protection | Protects lungs from toxic solvent vapors during application and hazardous dust particles during sanding. Must have organic vapor (OV) and particulate (P100) cartridges. |

| Nitrile Gloves | Skin Protection | Prevents absorption of toxic biocides and solvents through the skin, which can cause irritation and systemic health effects [8]. |

| Safety Goggles | Eye Protection | Protects eyes from splashes and airborne dust. A direct splash into the eye requires immediate medical attention [8]. |

| Coveralls | Full Body Protection | Prevents paint and dust from contaminating your skin and clothing, reducing the overall risk of exposure. |

The Importance of Ventilation

Working in a well-ventilated area is a key safety instruction [8]. Good airflow disperses the concentrated solvent fumes that evaporate from the paint, significantly reducing the amount you inhale. Whenever possible, work outdoors or in a space with strong, active ventilation like industrial fans.

What are the Safe Application Procedures for Antifouling Paint?

A successful and safe application of antifouling paint is about more than just getting the paint on the hull. Spills can contaminate the ground, overspray can drift, and improper cleanup can lead to hazardous waste entering the environment. Each step, from preparing your work area to cleaning your tools, carries a risk if not managed correctly. Thinking the job is done once the last coat is applied ignores the critical responsibility of safe cleanup and disposal.

A professional and safe application process begins before the paint can is even opened [17]. It involves preparing the work area to contain all debris, using safe methods for surface preparation to minimize toxic dust, and following strict protocols for cleanup and waste disposal. Every material that comes into contact with the paint—from rollers and brushes to masking tape and rags—must be treated as hazardous waste.

Work Area Preparation

Before you begin, lay down heavy-duty tarps or groundsheets that extend beyond the work area. This is crucial for containing all drips, spills, sanding dust, and paint chips, preventing them from contaminating the soil and water table.

Surface Preparation Safety

The preparation phase, especially on previously painted hulls, can be one of the most hazardous.

- The Dangers of Dry Sanding: Dry sanding old antifouling paint creates a cloud of highly toxic airborne dust containing biocides. This dust can be easily inhaled and can travel significant distances.

- Best Practice: The safest methods are wet sanding, which suppresses dust by turning it into a manageable slurry, or using a mechanical sander equipped with a high-efficiency vacuum attachment to capture dust at the source [5]. These methods are strongly recommended over dry sanding.

Mixing and Application

Always stir paint thoroughly, preferably with a mechanical mixer, as heavy biocides settle at the bottom [17, 30]. When applying, use rollers and brushes carefully to avoid splashes. Spray application generates significant overspray and aerosolized toxins and should typically be left to trained professionals with specialized ventilation and breathing apparatus [17, 8].

Cleanup and Waste Disposal

This is a critical final step. All used materials—rags, roller covers, brushes, masking tape, empty paint cans, and the plastic sheeting from your work area—are considered hazardous waste. They cannot be thrown in the regular trash. You must follow the specific disposal guidelines provided by your local boatyard or municipality. For a proper bond between coats, an epoxy tie coat like JDH263 Epoxy Tie Coat may be required, and its associated waste must also be handled safely [9].

What is the Challenge of Removal? Safe Stripping Methods

Years of old antifouling paint buildup must eventually be removed, and this process is often the most hazardous part of the entire maintenance cycle. The sheer volume of toxic material being removed, combined with the aggressive methods required, creates a significant risk of exposure and environmental contamination. Simply attacking the hull with a power sander without containment is irresponsible and dangerous, creating a massive amount of toxic dust that can harm you, your neighbors, and the local ecosystem.

Choosing the right removal method depends on your hull material and the thickness of the buildup. The overriding priority for any method must be the containment of all removed paint waste. There are three primary methods: mechanical, chemical, and professional media blasting. Each has its own set of safety protocols that must be strictly followed.

Method 1: Mechanical Removal (Scraping/Sanding)

This involves physically removing the paint. For thick layers, sharp scrapers can be effective. For finishing, sanding is required [5]. To do this safely, you must minimize dust.

- Technique: Use scrapers and sanders that are connected to a HEPA-rated vacuum system. This captures the vast majority of dust and debris at the point of creation.

- Alternative: Wet sanding is another option, which turns the dust into a slurry that can be contained on tarps, collected, and disposed of as hazardous waste.

Method 2: Chemical Stripping

This method uses chemical paint removers ("脱漆剂") to soften the old paint, allowing it to be scraped off [5].

- Compatibility: It is critical to choose a stripper that is safe for your hull material. Using a product not designed for fiberglass (GRP), for example, can permanently damage the gelcoat and underlying structure.

- Safety: Chemical strippers are themselves hazardous. Work in a well-ventilated area and wear appropriate PPE, including solvent-resistant gloves and splash-proof goggles [8].

Method 3: Professional Removal (Blasting)

For removing many thick layers of paint, media blasting (such as sandblasting, soda blasting, or dry ice blasting) is the most efficient method [5, 28]. This is strictly a professional job. It requires specialized equipment, full containment systems to capture all blast media and paint debris, and advanced respiratory protection.

Navigating the Law: How to Comply with Antifouling Paint Regulations?

Are you certain the antifouling paint you’re using is legal in your area? Regulations surrounding biocides are complex and constantly evolving. Using a banned product, or even a restricted product improperly, can lead to significant fines and environmental liability. Ignorance of the law is not a defense; as a boat owner, the responsibility for compliance falls squarely on your shoulders.

The legal landscape for antifouling paint is governed by international treaties, national laws, and even local marina rules. The most significant is the IMO’s International Convention on the Control of Harmful Anti-fouling Systems (AFS), which led to the global ban on the highly toxic biocide Tributyltin (TBT) and more recently, Cybutryne. This is why modern paints like our JD753 Tin-free self-polishing antifouling paint are standard [1, 16]. Many regions have gone further; for example, some states in the US and countries in Europe have strict limitations on the copper content or the leaching rate of paints sold to recreational boaters. In Europe, the Biocidal Products Regulation (BPR) governs which biocides can be used and sold. It is your responsibility to check and ensure that the product you buy and apply is compliant with all regulations in your home port and any areas you plan to visit. Always follow environmental best practices for boaters.

FAQs: Technical and Safety Q&A

Navigating the technical details of antifouling paint can be confusing, and when safety is on the line, you need clear answers. Misinformation about toxicity, disposal, and alternatives can lead to dangerous practices. Here are the answers to some of the most critical safety-related questions.

-

Is antifouling paint toxic to humans?

Yes. It contains biocides and solvents that are harmful. Exposure can occur through inhaling vapors and dust or through skin and eye contact, which can cause health problems ranging from irritation to more serious long-term issues [8]. This is why proper PPE is mandatory [8]. -

How do you dispose of old antifouling paint?

It must be treated as hazardous waste. All waste materials, including liquid paint, dried chips, used rollers, rags, and contaminated tarps, must be collected and disposed of according to your local boatyard, municipal, or regional regulations. Never put it in the regular trash or allow it to enter waterways. -

Are there any non-toxic antifouling alternatives?

Yes. The industry is moving towards more environmentally friendly options [4]. The most common are biocide-free "foul-release" coatings. These are typically silicone-based paints that create a super-slick surface that organisms cannot grip, rather than killing them.

![[Image Placeholder]> Prompt: A bright, clear image featuring a person in boatyard attire confidently answering a question from another boater. They are pointing to a product's technical data sheet, looking knowledgeable and helpful. [Image Placeholder]> Prompt: A bright, clear image featuring a person in boatyard attire confidently answering a question from another boater. They are pointing to a product's technical data sheet, looking knowledgeable and helpful.](https://jdmarinepaint.com/wp-content/uploads/2025/08/a-bright-clear-image-featuring-a-person-in-boatya-2.png)

Conclusion

Your commitment to safe and responsible boating is paramount. Handling antifouling paint requires knowledge, respect, and care. A clean hull is essential, but it must never come at the expense of your personal health or the health of our marine environment.

![]()