Is your coating system strong enough to withstand more than just spray? A single scratch on a standard coating can be a gateway for aggressive corrosion, compromising your entire multi-million dollar asset.

The primary benefits of a zinc-rich primer in a marine coating system stem from its ability to provide active sacrificial protection. Unlike conventional primers that only offer a passive barrier, a zinc-rich primer contains a high concentration of metallic zinc dust. When the coating is scratched or damaged, the zinc galvanically sacrifices itself to protect the exposed steel, preventing rust from forming and spreading beneath the coating film. This "self-healing" capability localizes damage, stops undercutting corrosion in its tracks, and drastically extends the service life and durability of the entire protective system, making it the superior foundation for assets in harsh marine environments.

This active defense mechanism is what sets zinc-rich primers apart. Let’s delve into what these specialized coatings are and how they provide this unmatched level of protection for your steel.

What Exactly is the Role of a Zinc-Rich Primer in a Marine System?

Have you ever wondered what the first layer applied to the steel of a new ship or offshore rig is? While many primers exist, high-specification projects demand something more than a simple layer of paint. Standard primers can create a strong bond, but they are vulnerable to failure the moment they are breached. This is where the chemistry of a zinc-rich primer becomes a game-changer, fundamentally altering the way we protect steel from its most determined enemy: corrosion. It’s not just a coating; it’s an active electrochemical guardian for the substrate.

A zinc-rich primer is a high-performance coating specifically engineered with a high concentration of metallic zinc dust suspended in a binder. Its role is fundamentally different from a standard primer. While other primers, like our dependable JDC53-31 Red Lead Alkyd Anti-Rust Paint, provide excellent barrier protection through inhibitive pigments, a zinc-rich primer adds an entirely different, active layer of defense known as cathodic protection. The high loading of zinc particles creates an electrically conductive film that allows the primer to galvanically interact with the steel. This active functionality, which we will explore in detail, is why it’s the specified foundation for the most demanding marine paint systems. These primers are generally categorized into two main types: inorganic (ethyl silicate) and organic (epoxy-based).

What is the Unmatched Benefit of Sacrificial Protection from Zinc-Rich Primers?

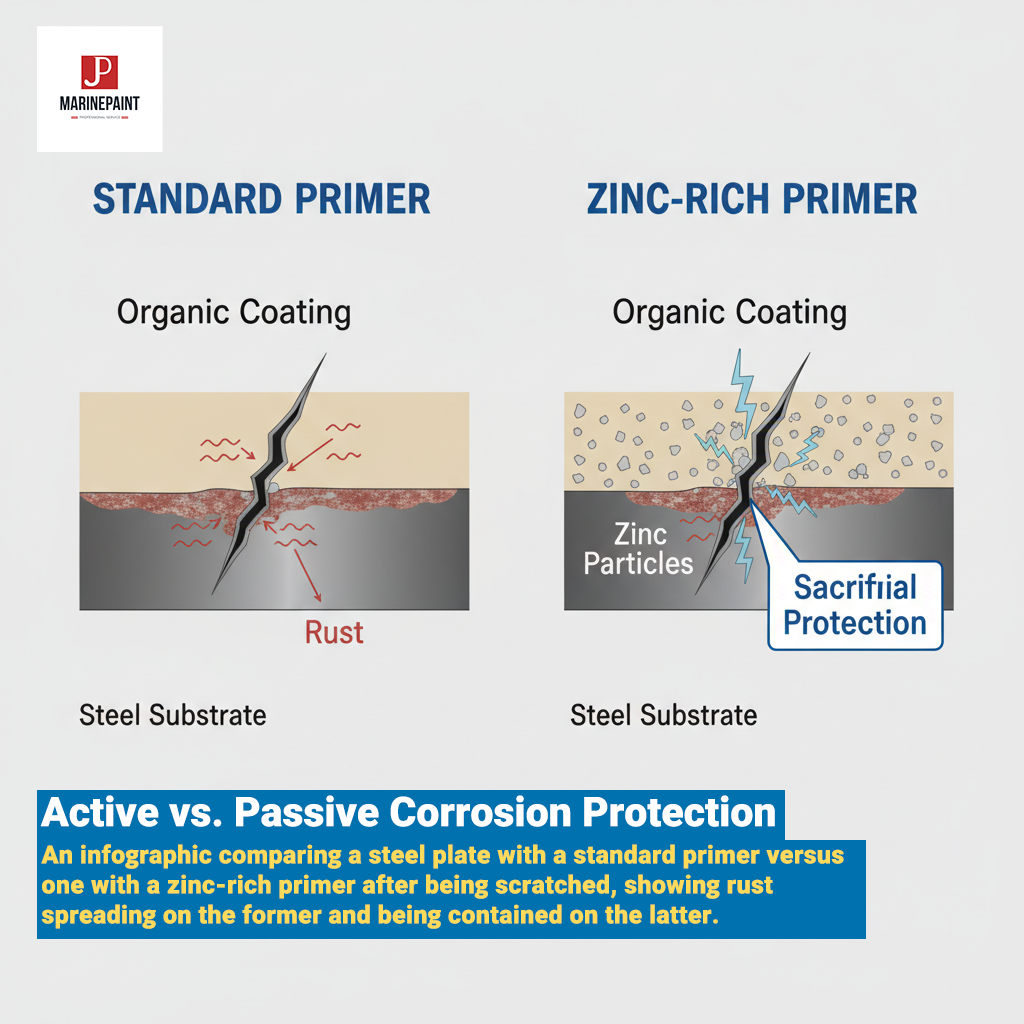

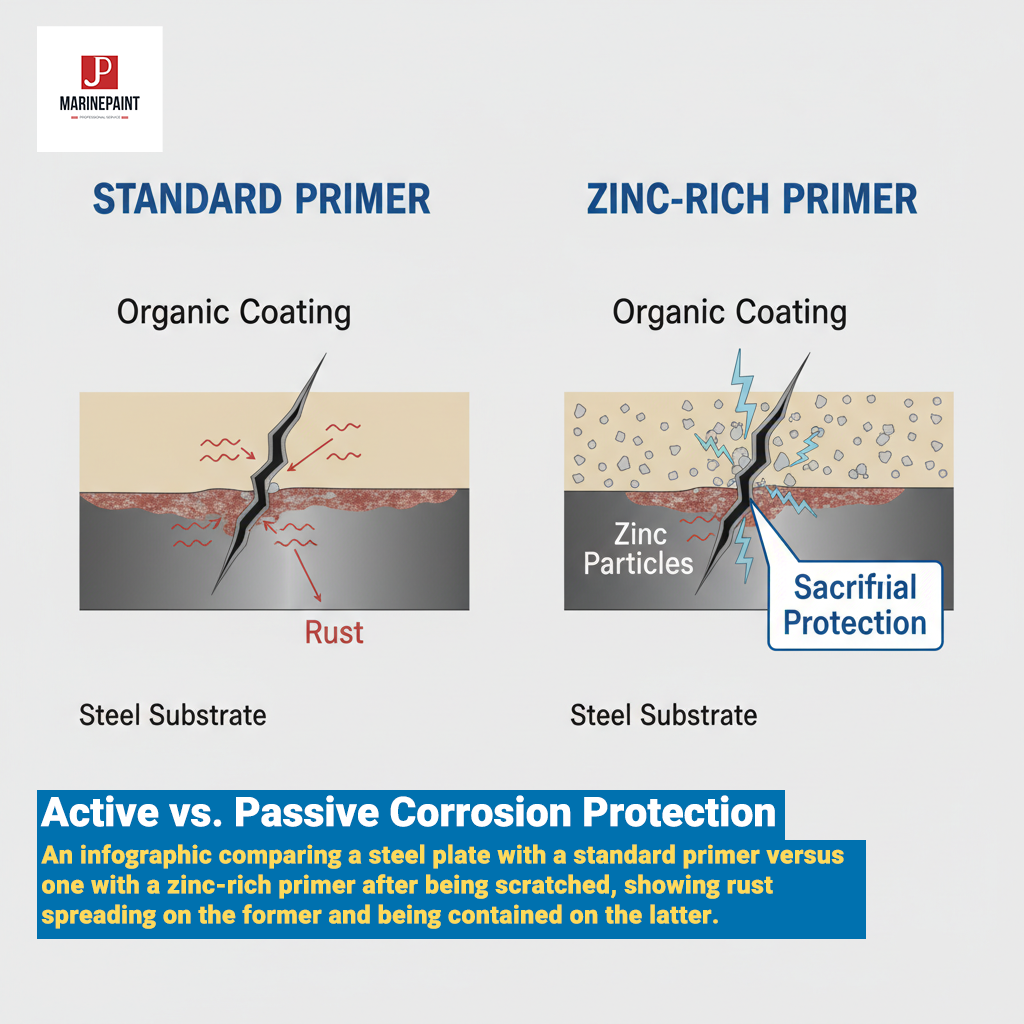

What happens when a chain or piece of equipment impacts your vessel’s deck and creates a deep scratch through the paint? With a conventional coating system, this is an open invitation for saltwater to attack the steel, causing rust that quickly spreads under the paint film, lifting it and causing widespread failure. This single point of damage can compromise an entire section of your asset. How can you ensure that such a small breach doesn’t lead to a massive problem? The answer lies in the unique science of sacrificial protection, a core benefit exclusive to zinc-rich primers.

The most significant of all the benefits of a zinc-rich primer in a marine coating system is its ability to provide active sacrificial (cathodic) protection. This isn’t just a physical barrier; it’s a continuously working electrochemical shield. It ensures that even when the coating is damaged, the steel remains protected, dramatically reducing maintenance costs and extending the asset’s operational life.

The Science Explained: How Zinc Protects Steel

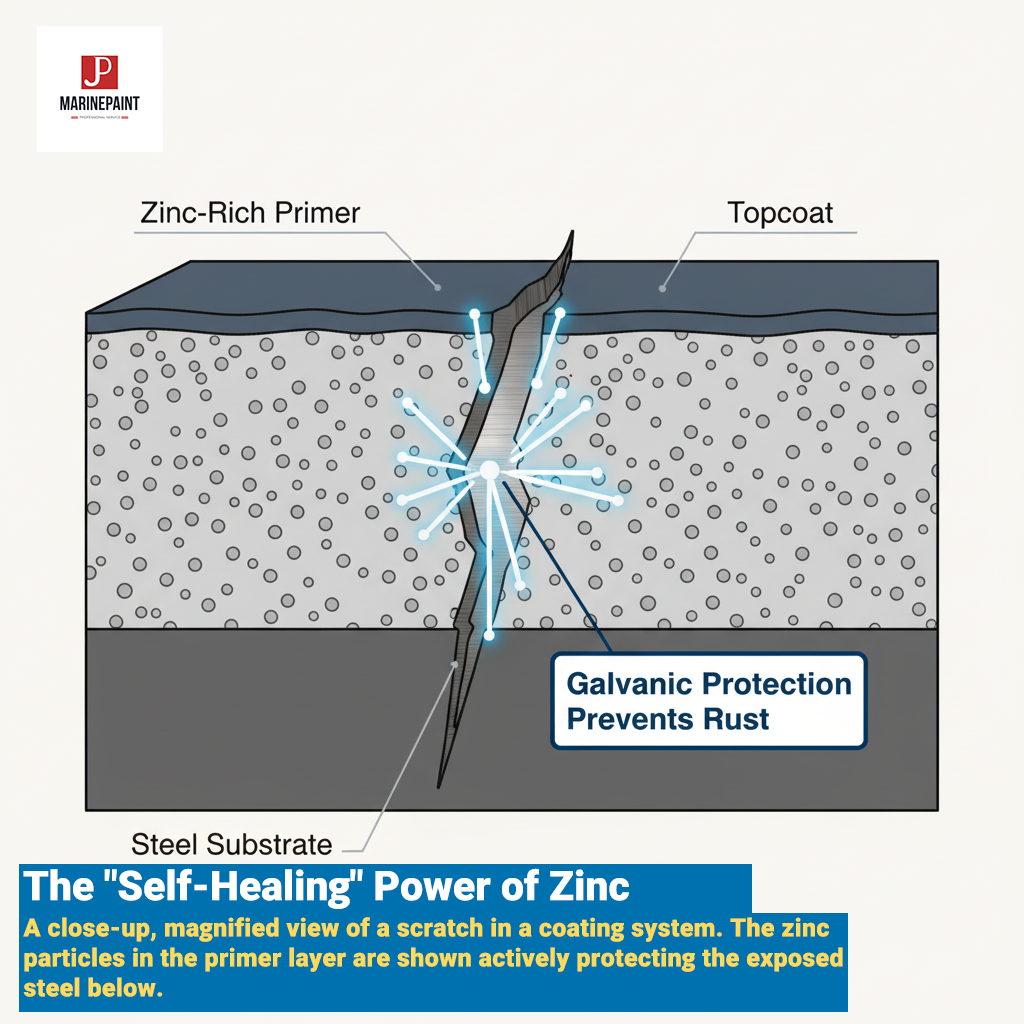

The principle of sacrificial protection is based on the galvanic series of metals. In simple terms, when two different metals are in electrical contact within an electrolyte (like saltwater), the more chemically active metal will corrode in preference to the less active one. Zinc is more active than steel. Therefore, when a zinc-rich primer is in direct contact with the steel substrate, the zinc particles act as the anode, and the steel becomes the cathode. The zinc essentially functions as a bodyguard, sacrificing itself by corroding away slowly over time to protect the steel from any corrosive attack.

The "Self-Healing" Advantage for Scratches

This sacrificial action creates a remarkable "self-healing" effect. When a scratch or gouge breaches the topcoats and primer, exposing the bare steel, a conventional system fails. But with a zinc-rich primer, the zinc particles immediately surrounding the exposed steel galvanically protect the bare area. This prevents rust from ever starting on the steel itself, a critical advantage that standard barrier coatings cannot offer.

Preventing Undercutting and Creep Corrosion

This "self-healing" directly prevents a catastrophic failure mode known as undercutting, or creep corrosion. Undercutting is the process where rust forms at a breach and spreads horizontally underneath the coating film, causing it to delaminate, peel, and flake. The sacrificial action of the zinc primer stops this process before it starts. By protecting the exposed steel at the scratch, it contains the damage to the point of impact, preserving the integrity of the entire surrounding offshore coating specification.

Are There Other Key Benefits in a Marine Coating System?

Is sacrificial protection the only reason to specify a zinc-rich primer? While that is its star quality, focusing solely on it overlooks other critical properties that make these primers the ideal foundation. A primer’s job is also to create a strong base for the rest of the coating system and to withstand the rigors of fabrication and service. A high-quality zinc primer delivers on these fronts as well, providing a multi-faceted performance that ensures the longevity of the entire system, from the steel all the way to the topcoat.

Beyond its primary sacrificial role, a zinc-rich primer provides several other essential benefits that contribute to a robust and long-lasting marine paint system. These advantages work together to create a foundation that is not only actively protective but also tough, durable, and reliable.

Providing a Superior Foundation for Topcoat Adhesion

Inorganic zinc primers, in particular, cure to a hard, porous surface. This slightly rough texture creates an ideal "anchor profile" for the subsequent epoxy intermediate coat to lock into. This strong mechanical bond between the primer and the mid-coat is critical for preventing inter-coat delamination and ensuring the cohesive strength of the entire system.

Exceptional Abrasion Resistance (Especially Inorganic Zincs)

Inorganic zinc silicate primers cure to form an incredibly hard, ceramic-like film. This provides exceptional resistance to abrasion and impact, making them an excellent choice for mechanically demanding environments like ship decks, cargo holds, and offshore platforms during construction and service.

Weldability and Damage Tolerance During Fabrication

For large-scale fabrication projects, special "weld-through" or "pre-fabrication" zinc-rich primers are available. These can be applied to steel plates at the mill. The coated steel can then be welded with minimal burn-back and without producing toxic fumes or compromising the quality of the weld, saving enormous time and labor compared to blasting and coating after assembly.

Conclusion

A zinc-rich primer is an indispensable first line of defense, offering active sacrificial protection, preventing corrosion from scratches, and creating a durable foundation for the entire coating system.

![]()