Ever wonder about the complex science that keeps a boat’s finish glossy and colorful under the relentless sun? It’s not magic; it’s advanced polymer chemistry engineered for the harsh marine environment.

For boat owners and industry professionals who want to move beyond brand names and understand the "how" and "why" behind a coating’s performance, this guide offers a technical deep dive. We will explore the destructive process of UV degradation and examine the specific chemistry that makes a UV-resistant marine paint effective. By comparing the technology behind different coating systems—from the primer to the topcoat—you will gain the knowledge to select a system that provides maximum protection and longevity for any maritime asset. This isn’t just about paint; it’s about investing in the right technology.

![[Image Placeholder]> **Prompt:** A microscopic, scientific-style illustration showing UV rays bouncing off a protective paint layer, with polymer chains underneath remaining intact. In the background, unprotected polymer chains are shown breaking apart. [Image Placeholder]> **Prompt:** A microscopic, scientific-style illustration showing UV rays bouncing off a protective paint layer, with polymer chains underneath remaining intact. In the background, unprotected polymer chains are shown breaking apart.](https://jdmarinepaint.com/wp-content/uploads/2025/08/a-microscopic-scientific-style-illustration-showi-2.png)

Understanding UV Degradation in the Marine Environment

Have you noticed how a boat’s vibrant colors can fade and its glossy finish turn chalky over time? This isn’t simple wear and tear; it’s a chemical breakdown caused by constant environmental assault. The sun, in combination with salt and water, relentlessly attacks the surface, accelerating its decay and compromising its protective qualities.

The primary culprit is ultraviolet (UV) radiation. Sunlight, particularly UV-A and UV-B rays, carries enough energy to break the chemical bonds within a paint’s polymer binder. You can learn more about the scientific process through resources detailing the effects of UV radiation on coatings. This breakdown manifests in several ways: a noticeable loss of gloss as the surface roughens on a microscopic level, color fade as pigments are affected, and chalking, where the degraded binder releases pigment particles as a dusty film. The coating can also become brittle, leading to cracking. The marine environment exacerbates this process significantly. Constant exposure to water and salt spray not only adds a corrosive element but also magnifies the sun’s effects, accelerating the degradation of even the toughest finishes.

The Chemistry of UV-Resistant Marine Paint: A Comparison of Topcoats

Not all paints are created equal, especially when it comes to fighting UV radiation. The secret to a long-lasting, glossy finish lies in the chemistry of the topcoat. Choosing the wrong type of paint can lead to premature failure, requiring costly and time-consuming rework. You might select a product that looks great initially, only to see it fade and degrade within a couple of seasons, leaving your vessel unprotected.

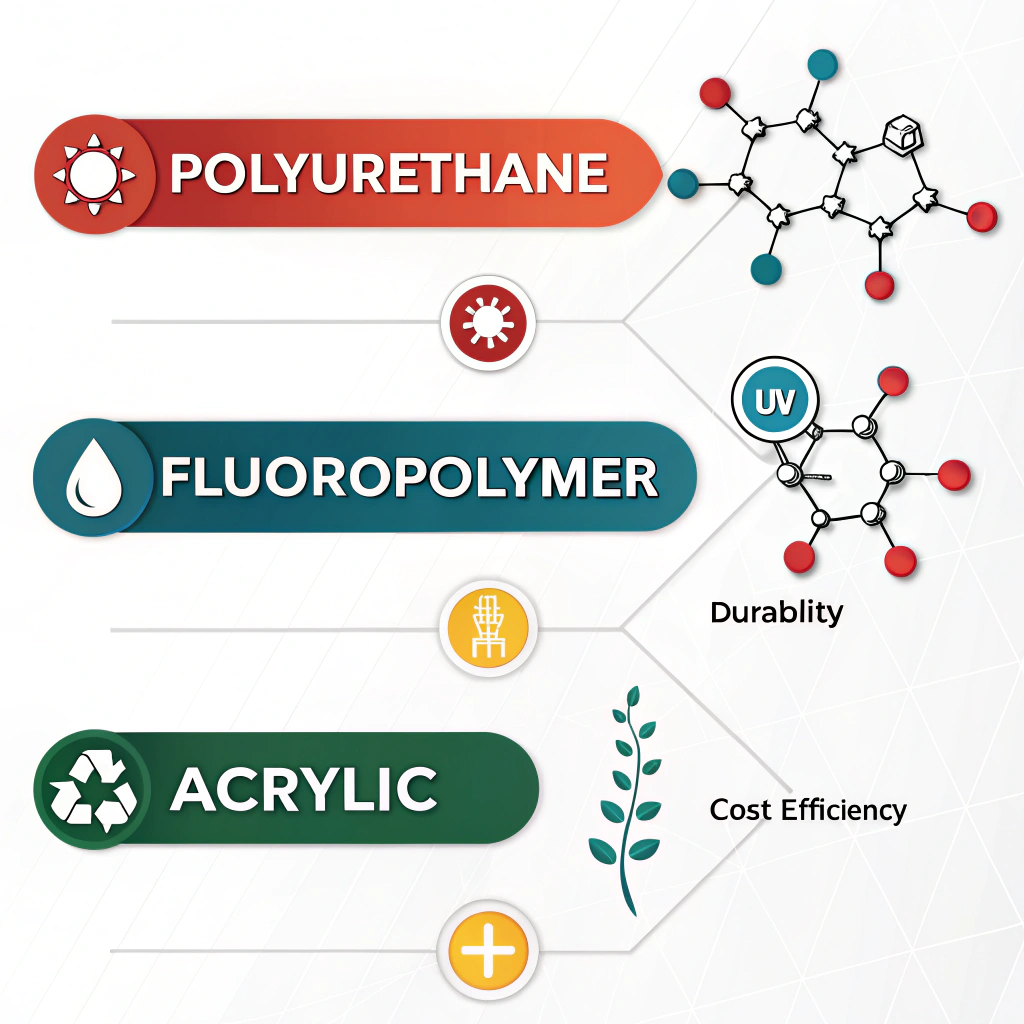

The solution is to select a topcoat with a polymer structure inherently designed to resist UV breakdown. The most effective UV-resistant marine paint systems rely on advanced resins that maintain their integrity under solar attack. The primary technologies used for topside coatings are two-part polyurethanes, high-performance fluoropolymers, and modern acrylics. Each offers a different level of durability and performance based on its unique chemical composition, allowing you to match the technology to the vessel’s needs and budget.

Two-Part Aliphatic Polyurethanes: The Industry Workhorse for UV Stability

Two-part polyurethane coatings are the industry standard for high-performance topside protection. These are two-component systems, consisting of a polyol resin (Part A) and an isocyanate hardener (Part B), often based on HDI for superior yellowing resistance. When mixed, they undergo a chemical reaction (cross-linking) to form an incredibly hard and durable paint film. The key to their UV stability lies in their "aliphatic" chemical structure, which is inherently resistant to being broken down by sunlight. This results in coatings with excellent weatherability (耐候性), exceptional gloss and color retention (保色保光性好), and resistance to yellowing over time. They are the go-to choice for the exterior protection of ship hulls and superstructures. For a finish that exemplifies this technology, our JD918 Acrylic Polyurethane Hull Paint (Yellowing resistance) is formulated specifically for superior non-yellowing performance and durability.

Fluoropolymers (Fluorocarbon Paint): The Ultimate in UV and Chemical Resistance

For the most demanding applications where long-term performance is paramount, fluoropolymer coatings are the ultimate choice. The technology is based on the carbon-fluorine (C-F) bond, one of the strongest and most stable chemical bonds in organic chemistry. This bond is extremely difficult for UV radiation to break, giving fluorocarbon paints unparalleled resistance to weathering. This chemical stability translates directly to superior, long-term color and gloss retention that far exceeds even the best polyurethanes. Due to their exceptional durability and high cost, they are positioned as a premium coating system for superyachts, steel bridges, and other critical infrastructure where maintenance is difficult and maximum lifespan is the goal. Our JDFT810 Fluorocarbon Topcoat leverages this advanced chemistry to deliver the highest level of protection available.

Modern Acrylic and Silicone-Alkyd Enamels

Modern single-part enamels have significantly closed the performance gap with older paint technologies. While traditional alkyds offer good protection, modified acrylic topcoats provide enhanced durability and weather resistance. These paints are formulated with advanced acrylic resins that offer good adhesion, color retention, and water resistance in a user-friendly, single-component package. A key advantage of certain modified acrylics is their compatibility with older paint systems. For example, our JDB903 Modified Acrylic Topcoat is uniquely designed to be used as a transition layer over existing alkyd paints without causing the lifting or wrinkling issues common with stronger coatings, making it an excellent choice for refurbishment projects.

The Unsung Hero: Why Your Primer System is Crucial for UV Protection

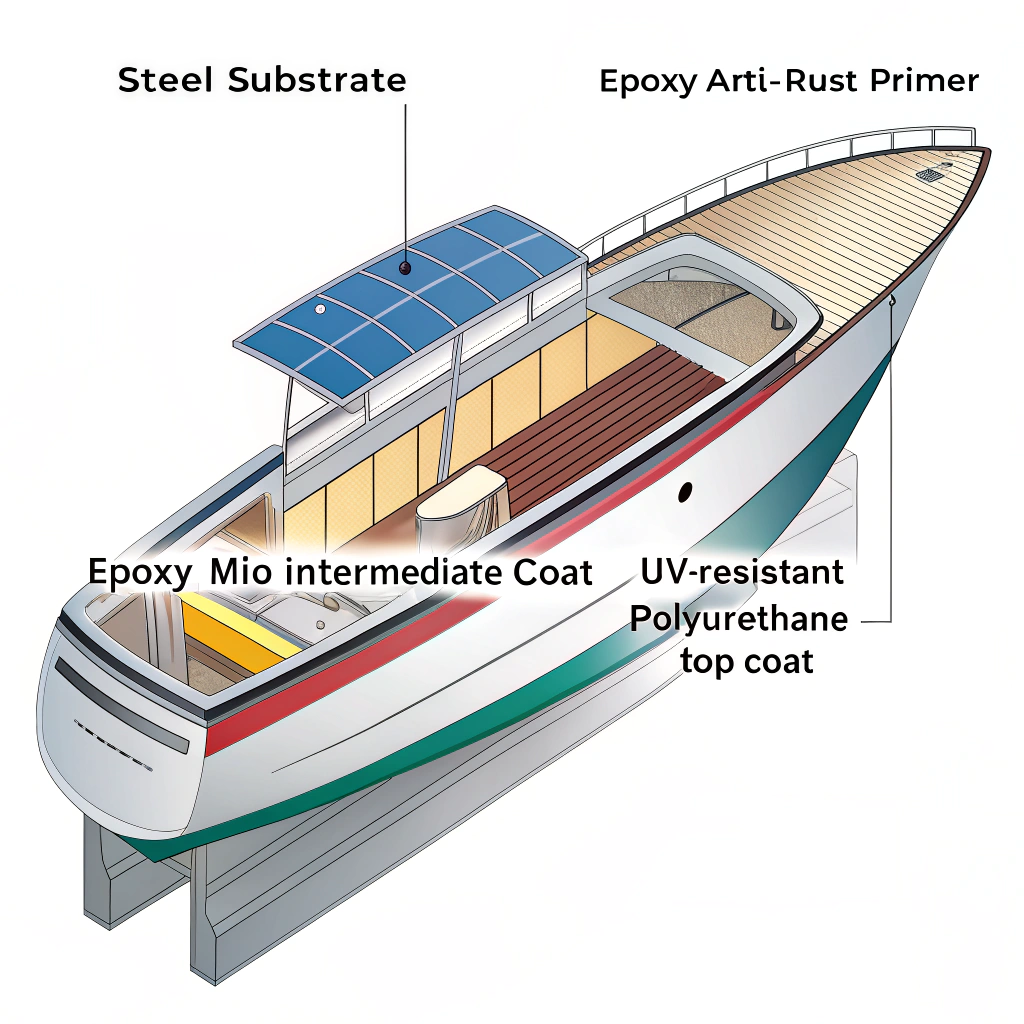

A brilliant, UV-resistant topcoat can capture all the attention, but its performance is completely dependent on the foundation it’s built upon. Applying a high-tech topcoat over a poorly prepared or incompatible primer is a recipe for failure. The entire system can delaminate, blister, or peel, wasting all the money and effort spent on the finish.

The primer system is the unsung hero that ensures the longevity of your entire coating job. Its role is twofold: to provide tenacious adhesion to the substrate and to create a barrier against corrosion, which is the underlying enemy of any paint system. A complete system often includes a primary anti-rust primer and an intermediate or tie-coat to build thickness and ensure compatibility between layers. Neglecting the foundation is the most common and costly mistake in marine painting.

Epoxy Primers: The Foundation for Adhesion and Corrosion Control

Two-part epoxy primers are the ideal foundation for any high-performance marine coating system. Composed of an epoxy resin and a polyamide or amine curing agent, they create a tough, durable film with outstanding properties. Their primary function is to create a tenacious bond to the substrate, whether it’s properly prepared steel, aluminum, or galvanized surfaces. Just as importantly, they form a highly effective barrier to water and salt, providing excellent anti-corrosion and salt spray resistance that prevents rust from forming beneath the topcoat and causing it to fail. Products like our JDH815 Iron Oxide Red Epoxy Primer are designed specifically to deliver this combination of superior adhesion and corrosion protection.

Tie-Coats and Intermediate Coats: Building the Perfect System

A multi-layer paint system often requires specialized intermediate coats to ensure compatibility and build protection. A tie-coat is a crucial layer that acts as a chemical bridge between two otherwise incompatible paint types. For instance, when applying a strong polyurethane topcoat over an epoxy primer, a product like our JDH263 Epoxy Tie Coat is used to ensure perfect adhesion and prevent system failure. For added protection in harsh environments, an epoxy intermediate coat containing micaceous iron oxide (MIO) is often specified. The plate-like MIO particles align within the paint film to create a laminar barrier, which significantly impedes the path of moisture and adds to the system’s overall film thickness and durability. Our JDH817 MIO Epoxy Anti-Rust Tie Coat serves this exact purpose, enhancing the protective qualities of the entire paint system.

Measuring Performance: What do Dry Film Thickness and Other Specs Mean?

When selecting a marine coating, the technical data sheet (TDS) is your most important tool. However, it can be filled with jargon that is confusing to the uninitiated. Ignoring these specifications can lead to applying the paint incorrectly, drastically reducing its lifespan and protective capabilities.

Understanding a few key metrics will empower you to apply the coating like a professional and ensure you get the performance you paid for. Key specifications like Dry Film Thickness (DFT), recoat intervals, and volume solids are not just numbers; they are critical instructions for achieving a successful outcome.

- Dry Film Thickness (DFT): This is the thickness of the paint film after all the solvents have evaporated. It is perhaps the most critical parameter for performance. Applying a coating too thin will not provide adequate corrosion or UV protection. Applying it too thick can lead to improper curing, cracking, and solvent entrapment. Every TDS specifies a recommended DFT range (e.g., 50μm) to achieve the intended durability.

- Recoat Intervals: This specifies the minimum and maximum time you must wait before applying the next coat of paint. Applying the next coat too soon can trap solvents, while waiting too long can compromise the chemical bond between layers, requiring mechanical sanding to ensure adhesion.

- Volume Solids: Expressed as a percentage (e.g., 50%), this metric tells you how much of the paint’s volume remains on the surface as the protective film after the liquid solvents have evaporated. A higher volume solids content means you can achieve a given DFT with less liquid paint, making it a more efficient coating.

Frequently Asked Questions (FAQs) for the Technical Buyer

What does "aliphatic" vs. "aromatic" mean for polyurethane paints?

This refers to the chemical structure of the isocyanate hardener. "Aromatic" polyurethanes are tough and cost-effective but will yellow and degrade under UV exposure, making them suitable only for primers or interior use. "Aliphatic" polyurethanes, like those made with HDI hardeners, are non-yellowing and designed for exterior topcoats that require excellent weather and UV resistance.

Is a thicker paint coat always better?

No. Every paint is formulated to perform within a specific Dry Film Thickness (DFT) range. While applying a coat too thin is a clear problem, applying it too thick can prevent proper curing, lead to a brittle film, and increase the risk of solvent entrapment, which can cause blisters and failure later on. Always follow the manufacturer’s recommended DFT.

What is a "self-polishing" antifouling paint?

A self-polishing antifouling paint is an advanced coating designed to prevent marine growth on the hull below the waterline. It is formulated with a special copolymer resin that slowly dissolves (or "polishes") in seawater, continuously releasing fresh biocides to the surface. This action not only provides long-lasting fouling protection but also maintains a smooth hull surface, which helps save on fuel costs. Our JD753 Tin-free self-polishing antifouling paint is an example of this technology.

Conclusion

Choosing the right UV-resistant marine paint is about understanding the technology. It requires selecting a complete system—from primer to topcoat—that works together to deliver maximum protection and long-lasting aesthetic appeal.

![]()