Is your marine asset battling constant degradation? Maintenance is relentless, but traditional coating methods often demand pristine surface preparation that’s rarely achievable in the field.

Surface tolerant epoxy for marine maintenance is a game-changing solution engineered to overcome these challenges, delivering robust protection even on less-than-ideal surfaces. It’s specifically formulated to penetrate rust, displace moisture, and achieve excellent adhesion where conventional epoxies would fail due to stringent surface preparation demands. This innovative coating minimizes the need for extensive blasting, reducing downtime and costs, while still providing superior corrosion resistance. It’s an invaluable tool for critical repairs in challenging marine environments, ensuring asset longevity and operational efficiency.

![[Image placeholder]**Image Title:** Surface Tolerant Epoxy: Repairing Rust on a Ship's Hull**Image Description:** A worker applying a thick, dark coat of surface tolerant epoxy primer directly onto a moderately rusted but prepared steel ship hull, demonstrating its capability to adhere to imperfect surfaces.**Image Prompt:** A realistic photo showing a marine worker in PPE applying a dark grey, high-build epoxy coating with a roller onto a visibly, but tightly, rusted steel ship hull. The background shows part of a dry dock or marine facility. Focus on the texture of the applied coating and the prepared rust. [Image placeholder]**Image Title:** Surface Tolerant Epoxy: Repairing Rust on a Ship's Hull**Image Description:** A worker applying a thick, dark coat of surface tolerant epoxy primer directly onto a moderately rusted but prepared steel ship hull, demonstrating its capability to adhere to imperfect surfaces.**Image Prompt:** A realistic photo showing a marine worker in PPE applying a dark grey, high-build epoxy coating with a roller onto a visibly, but tightly, rusted steel ship hull. The background shows part of a dry dock or marine facility. Focus on the texture of the applied coating and the prepared rust.](https://jdmarinepaint.com/wp-content/uploads/2025/09/a-worker-applying-a-thick-dark-coat-of-surface-tolerant-epoxy-primer-directly-onto-a-moderately-rusted-but-prepared-steel-ship-hull-demonstrating-its-capability-to-adhere-to-imperfect-surfaces.png)

The ability of these epoxies to perform under conditions that would cripple traditional coatings makes them indispensable. Let’s dive deeper into what makes them so effective.

Defining Surface Tolerant Epoxy for Robust Marine Maintenance?

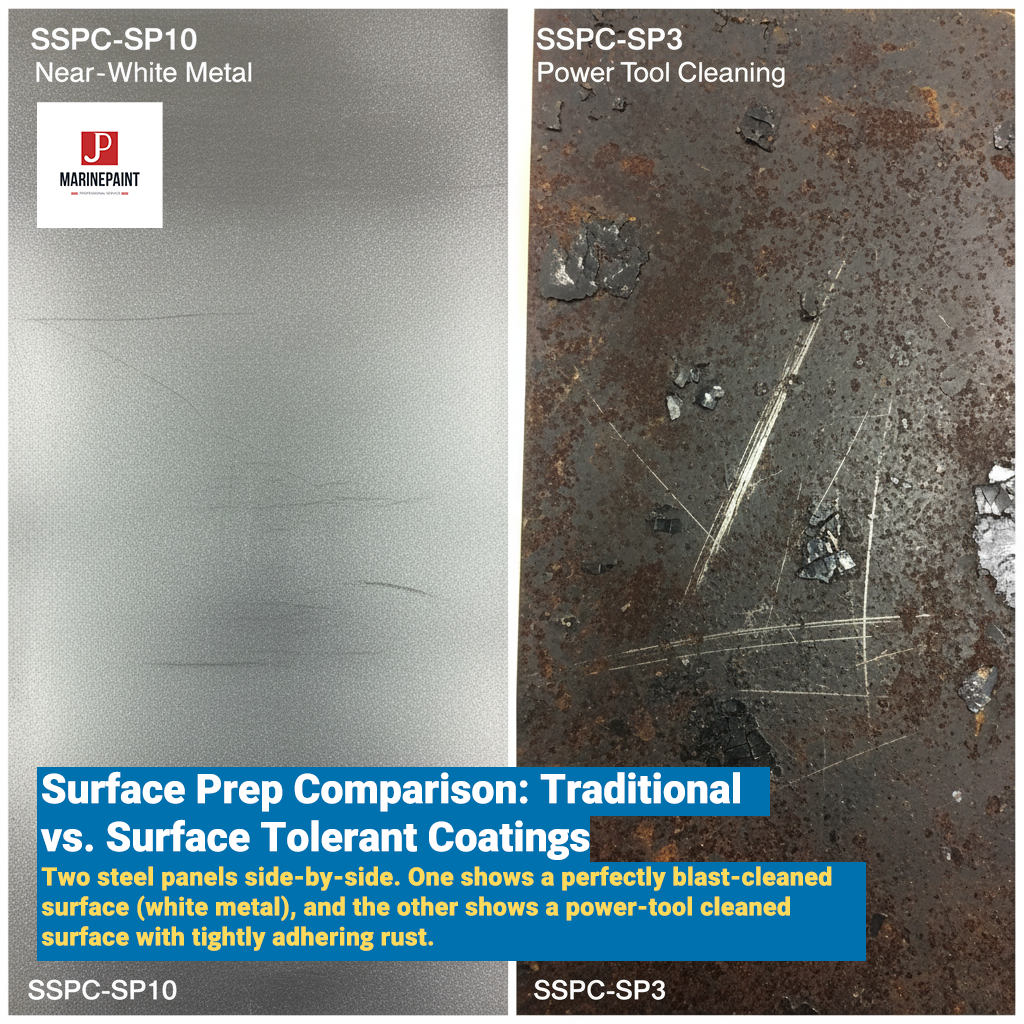

Have you ever faced the dilemma of needing to coat steel in a marine environment, but abrasive blast cleaning simply isn’t an option? Traditional high-performance epoxies demand near-perfect surface preparation, typically to standards like SSPC-SP10 (Near-White Metal Blast Cleaning). This is often impractical, costly, or even impossible for in-situ repairs, tight schedules, or hard-to-reach areas. The solution lies in a specialized class of coatings designed to work with—not against—these real-world challenges.

Surface tolerant epoxy for marine maintenance is a high-performance, two-component coating specifically formulated to achieve excellent adhesion, protection, and durability even when applied over imperfectly prepared steel surfaces. Unlike conventional epoxies, which would delaminate quickly without pristine prep, these advanced formulations can adhere effectively to surfaces cleaned to less stringent standards, such as hand tool cleaning (SSPC-SP2), power tool cleaning (SSPC-SP3), or commercial blast cleaning (SSPC-SP6), provided all loose rust and contaminants are removed. Key characteristics include its unique ability to penetrate tightly adhering rust, displace entrapped moisture, and effectively "wet out" the substrate, establishing a strong bond where other coatings would fail. These coatings are essentially a specialized anti-corrosive primer or an epoxy mastic coating designed for scenarios where optimal surface preparation is not feasible.

Unpacking the Critical Benefits of Surface Tolerant Epoxy for Marine Applications

When time is money and perfect surface preparation is a luxury you can’t afford, what’s your game plan for preventing catastrophic corrosion? The challenges of marine maintenance often mean compromising on coating application, leading to increased costs and shortened service life. However, certain coating technologies are designed to bridge this gap, offering a pragmatic solution without sacrificing critical protection. Understanding these capabilities can revolutionize your maintenance strategy and your asset integrity management.

The strategic benefits of surface tolerant epoxy for marine maintenance directly address the practical limitations of real-world repair and upkeep. They provide robust protection by uniquely adapting to less-than-ideal conditions, making them an invaluable tool for prolonging the life of critical marine infrastructure and vessels.

Reduced Surface Preparation Costs and Time Savings

The primary advantage of surface tolerant epoxies is their significantly less stringent surface preparation requirements. This directly translates to lower labor costs, as less time is spent blasting or grinding the surface. Reduced equipment rental (no need for complex blasting equipment) and faster project turnaround are also major benefits, especially crucial during limited dry dock periods or operational interruptions. This makes them ideal for inaccessible areas where abrasive blasting is impossible or unsafe due to environmental restrictions or structural constraints.

Adhesion to Less Than Ideal Substrates: The "Rust Penetrator" Advantage

These epoxies are formulated with specific resins and specialized wetting agents and adhesion promoters that allow them to penetrate existing tightly adhering rust and corroded surfaces. They actively displace moisture and oxygen to achieve a strong mechanical and chemical bond even where traditional epoxies would fail. This property allows them to effectively encapsulate tightly adhering rust, preventing further corrosion under the film and locking it away from the steel substrate.

Versatility and Broad Application Window

Many surface tolerant epoxies are designed for a wide range of temperatures and humidity levels, making them suitable for year-round application in diverse marine environments—from hot, humid tropical zones to colder, temperate regions. Formulations with moisture displacement capabilities can even be applied to damp or power-washed surfaces, a significant advantage in fluctuating marine conditions where achieving a perfectly dry surface is often impossible.

Excellent Corrosion Resistance and Barrier Protection

Despite their surface tolerance, these epoxies provide robust barrier protection. They create a thick, impermeable film that prevents corrosive elements like water and chloride-ion attack from reaching the steel substrate. Their inherent chemical resistance further enhances this protection, ensuring long-term corrosion control even in aggressive marine and industrial settings.

Key Areas Benefiting from Surface Tolerant Epoxy in Marine Environments

Where exactly does surface tolerant epoxy for marine maintenance prove its worth? The demanding and often confined spaces of maritime assets, coupled with tight operational schedules, present unique challenges for corrosion control. These are the settings where this specific coating technology truly shines. Its unique formulation allows it to address common problems that traditional coatings struggle with, providing solutions for critical areas prone to persistent degradation.

Surface tolerant epoxies are invaluable across a wide spectrum of marine and industrial applications, particularly where comprehensive surface preparation is impractical or impossible. Their versatility makes them a go-to choice for managing corrosion under insulation (CUI) coatings and extending the service life of critical infrastructure.

Ballast Tanks and Voids: Preventing Hidden Corrosion

Ballast tanks and enclosed voids are notorious for being difficult, costly, and hazardous to abrasive blast clean completely. These spaces are prone to rapid corrosion due to constant exposure to seawater. Surface tolerant epoxies are ideal for quick, effective, and compliant maintenance in these critical spaces, providing reliable protection with minimal preparation, making them a cornerstone of ballast tank repair.

Deck Maintenance and Splash Zones

For localized repairs on decks, gangways, equipment, and structures within the splash zone, constant moisture, salt spray, and physical impact make traditional prep arduous. Surface tolerant epoxies provide a robust solution that can handle abrasion and impact, restoring protection quickly in these high-exposure areas.

Hull Repairs (Above and Below Waterline)

They are excellent for localized patch repairs on ship hulls,

especially above the waterline where speed is key during port calls. While specialized, some formulations of wet surface tolerant coating products can even be applied underwater for emergency or temporary repairs, though this application requires specific expertise.

Jetty Piles, Offshore Platforms, and Port Infrastructure

For large, fixed structures like jetty piles, offshore platforms, and general port infrastructure, full abrasive blasting is often environmentally restricted, logistically complex, or impractical. Surface tolerant epoxies offer a cost-effective, long-term solution for maintaining these extensive assets without significant operational disruption.

Pipework, Valves, and Machinery Protection

Complex shapes and components like pipework, valves, and machinery are difficult to prepare thoroughly. Surface tolerant epoxies provide vital protection against corrosion in these critical mechanical systems, ensuring their continued function and preventing costly replacements.

Understanding the Boundaries of Surface Tolerant Epoxy in Marine Use

Given their impressive capabilities, is surface tolerant epoxy always the best choice? While a powerful tool, it’s not a universal panacea. Misunderstanding its limitations can lead to disappointing results and wasted investment. Like any specialized product, to truly harness its power and achieve maximum asset integrity, it’s imperative to recognize its specific sweet spots and, crucially, its boundaries. Effective long-term industrial maintenance epoxy strategies require a clear understanding of where these coatings excel and where more traditional methods are still preferred.

While offering significant tactical advantages, a surface tolerant epoxy for marine maintenance must be used with a clear understanding of its appropriate application and limitations. It’s a pragmatic choice for challenging conditions, but wise selection and application are still paramount.

Not a Substitute for Optimal Surface Preparation When Possible

It is critical to understand that while surface tolerant, these epoxies are not a magic bullet. The better the surface preparation, the longer any coating system—including surface tolerant ones—will last. They are a pragmatic choice for sub-optimal conditions, providing reliable performance in a pinch, but they typically do not yield the same ultimate lifespan as a traditional, ideal coating system applied to a perfectly blast-cleaned (SSPC-SP10) surface.

Removal of Loose Rust and Contaminants is STILL Critical

"Surface tolerant" emphatically does not mean "no preparation." All loose, flaky rust, scale, old delaminating paint, soluble salts (which can cause osmotic blistering), grease, and oil MUST be thoroughly removed. Methods like aggressive power washing and power tool cleaning (SSPC-SP3) are essential to create a stable, clean enough surface for the epoxy to bond effectively and achieve true substrate penetration.

Product Specificity and Technical Data Sheets (TDS)

Not all surface tolerant epoxies are created equal. It is absolutely essential to consult the manufacturer’s Technical Data Sheet (TDS) for specific surface preparation requirements, recommended application windows (temperature, humidity), pot life, cure time, and recoat window. These documents provide crucial guidance for successful application.

Topcoat Requirements

While providing excellent anti-corrosive primer/intermediate protection, most surface tolerant epoxies are not inherently UV-stable. For external, exposed areas like decks and superstructures, they often still require a UV-stable topcoat (e.g., polyurethane) for long-term color and gloss retention, as well as enhanced weatherability.

Conclusion

Surface tolerant epoxy is an invaluable tool for marine maintenance, offering a pragmatic balance between performance and efficient application in challenging environments.

![]()