Maximize Maritime ROI: Silicone vs. Biocide in Fouling Release Coatings

Hey maritime pros! Ever feel like you’re in a never-ending battle against pesky marine biofouling? You’re not alone! Every vessel sailing the high seas faces the challenge of organisms clinging to its hull, dragging down efficiency and impacting the planet. The big question for ship owners and operators? It all comes down to silicone vs. biocide-based fouling release coatings. This isn’t just about paint; it’s about smart strategy to maximize your maritime ROI. Let’s dive deep into these two heavyweights, exploring how they truly stack up in the quest for peak performance.

In today’s world, where sustainability and slashing costs are top priorities, your choice of antifouling strategy is more crucial than ever. Biofouling isn’t just an eyesore; it’s a drag – literally! Increased hull roughness means your engines work harder, burn more fuel, and pump out more emissions. That means higher operational expenditure (OPEX) and a bigger environmental footprint. Understanding the ins and outs of both silicone and biocide-based approaches is absolutely key for hull performance optimization, achieving serious fuel consumption reduction, and making brilliant marine coating selection decisions.

The War Against Fouling: Biocide-Based Antifouling Coatings

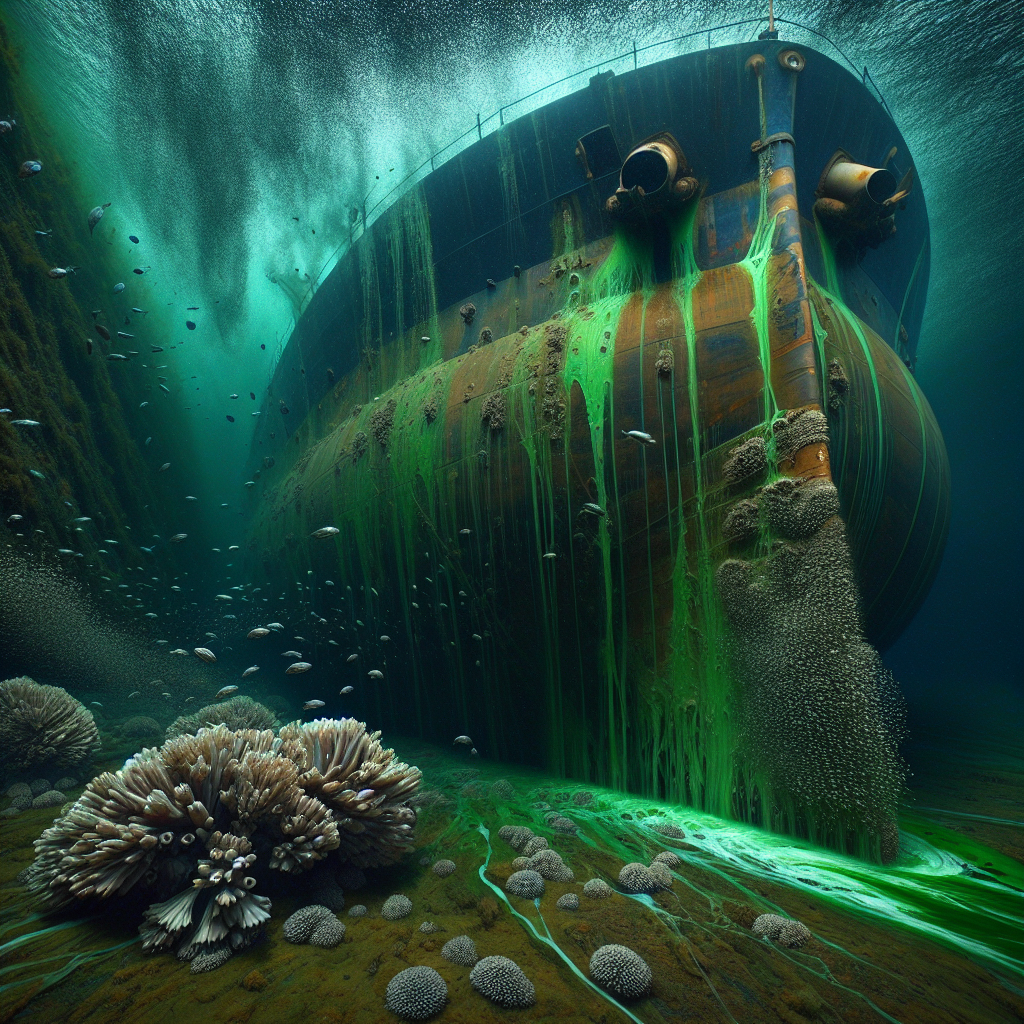

For years, biocide-based antifouling paints were the undisputed champions. Their mechanism? Simple yet effective: release toxic substances (like copper compounds or other organic active ingredients) to create a ‘no-go’ zone for marine life. As your ship cruises, these biocides leach out, forming a protective, albeit toxic, shield.

How Biocides Work and Their Impact

Biocide-based coatings create an uninhabitable environment for marine growth. As the ship moves through water, the biocides leach out, forming a toxic layer that deters barnacles, algae, and other organisms. The effectiveness of these coatings depends on the type and concentration of biocides, as well as the coating’s release rate. We’ve got reliable options like our JD713 Chlorinated Rubber Antifouling Paint and JD744 Chlorinated Rubber Antifouling Paint for robust performance. Looking for advanced, tin-free solutions? Our JD753 Tin-free self-polishing antifouling paint provides excellent, lasting protection while meeting modern antifouling regulations. Plus, our JDL44-83 Bituminous Antifouling Paint offers specialized protection.

Advantages of Biocide-Based Coatings

- Seriously Tried & Tested: Biocide paints have a long track record, so their application and performance are well understood.

- Broad Spectrum Protection: They’re effective against a wide range of marine organisms in diverse environments.

- Cost-Effective Initial Application: Often, the upfront cost of biocide-based paints can be lower than some advanced fouling release systems.

Disadvantages and Environmental Concerns

But hold on – there’s a catch! Biocide coatings are under serious scrutiny. Why? Because continuously releasing biocides into our oceans isn’t exactly ocean-friendly. It harms non-target organisms and contributes to pollution. This has sparked stricter environmental compliance shipping regulations and a huge push towards sustainable maritime solutions. Ever heard of IMO environmental regulations? They’re constantly evolving, nudging us towards truly eco-friendly antifouling strategies. Plus, that biocide release has a lifespan. Once it’s gone, so is the protection, leading to more frequent reapplications and higher vessel maintenance costs.

The Rise of Silicone-Based Fouling Release Coatings

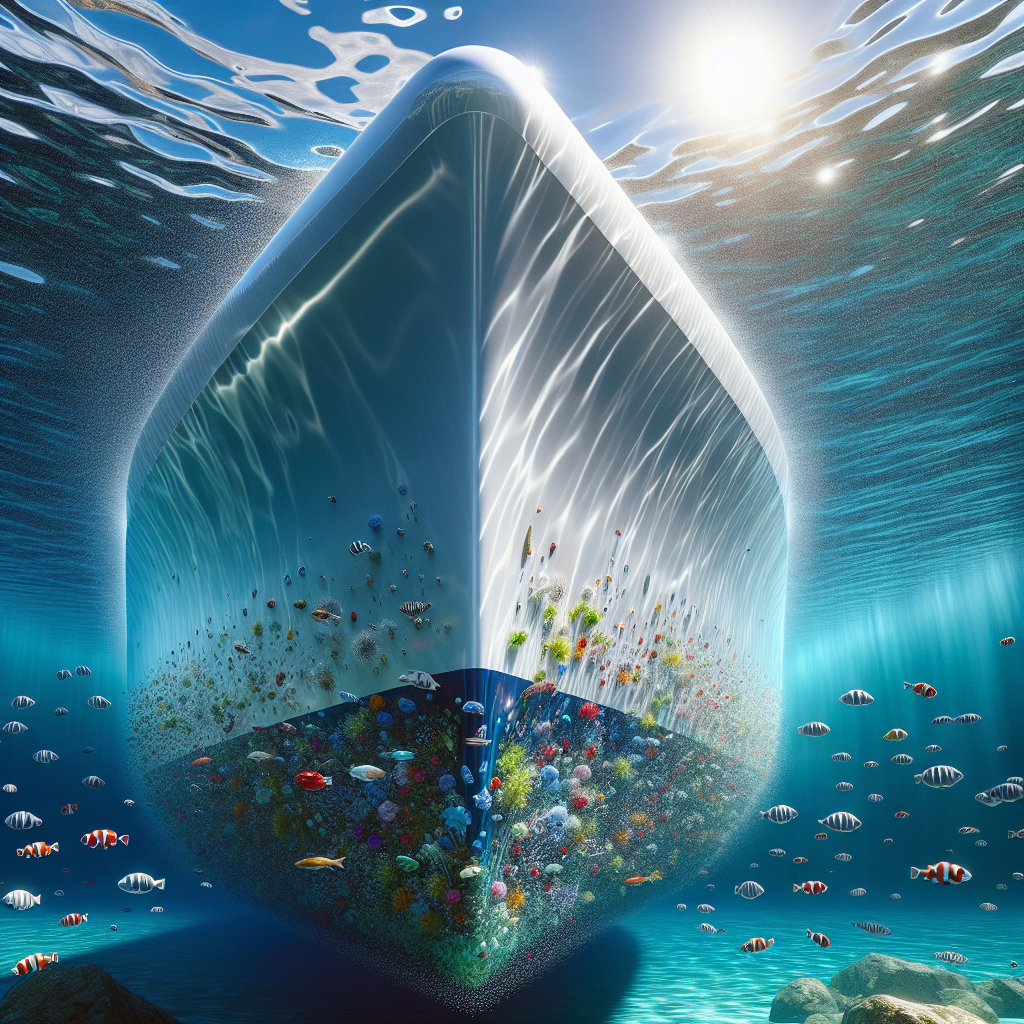

So, what’s the game-changer? Enter silicone-based fouling release coatings! These guys are a total breath of fresh air, especially with growing environmental concerns and the demand for higher efficiency. Their secret? They don’t kill marine organisms; they simply make it incredibly hard for them to stick!

The Mechanism of Fouling Release

Imagine a super-slick, low-surface-energy surface. Marine life tries to latch on, but just can’t get a good grip. When your vessel moves, the sheer force of the water gently sweeps away any loose hitchhikers. Even at anchor, minimal adhesion means easy cleaning. This isn’t just smart; it’s cutting-edge drag reduction technology!

Advantages of Silicone-Based Coatings

Here’s why silicone is winning hearts:

- Seriously Eco-Friendly: No harmful biocides released! This totally aligns with green shipping initiatives and those tough environmental compliance shipping rules. Big win for Mother Ocean!

- Unbeatable Fuel Efficiency: Keep that hull smooth as glass, and you slash hydrodynamic drag. That means massive fuel consumption reduction – straight cash savings and a smaller carbon footprint. Boom!

- Built to Last: Silicone coatings are tough! They often boast a much longer service life, stretching out your dry-docking intervals and cutting down vessel maintenance costs.

- Less Cleaning, More Sailing: Their incredible fouling release properties mean less frequent hull cleaning. More operational uptime, more savings!

- Performance You Can Trust: Their physical mechanism means predictable, consistent performance. Essential for boosting fleet efficiency!

Challenges of Silicone-Based Coatings

Okay, let’s be real, no solution is perfect.

- Higher Initial Cost: The upfront investment for silicone-based coatings can be higher. But think long-term – the fuel and maintenance savings often blow this out of the water!

- Application Complexity: Applying silicone needs a skilled hand and specific conditions to nail optimal performance.

- Potential for Mechanical Damage: They’re durable, but severe bumps or scrapes can damage that super-smooth surface, potentially compromising its magic.

Comparing ROI: Silicone vs. Biocide-Based Fouling Release

Alright, let’s get down to brass tacks: silicone vs. biocide-based fouling release – which one truly delivers the goods for your bottom line? It’s not just about the initial paint price; it’s about the full picture: fuel, maintenance, and meeting those ever-growing environmental demands.

Lifecycle Costing of Coatings

To really compare apples to apples, you MUST embrace a lifecycle costing coatings approach. We’re talking about EVERY cost over the coating’s entire lifespan, including:

- Initial Material and Application Costs: The upfront expenditure for the paint and its application.

- Fuel Savings: This is HUGE! Even a small percentage reduction for a big vessel means millions over its lifetime.

- Maintenance and Cleaning Costs: The expenses related to hull cleaning, repairs, and reapplication of coatings.

- Dry-docking Intervals: How often are you taking your ship out of service?

- Compliance Costs/Benefits: Avoid fines, gain kudos for being green!

While biocides might look cheaper at first glance, those lifecycle costs can skyrocket thanks to higher fuel bills and more frequent maintenance. Silicone? Higher initial outlay, sure, but the ROI through massive fuel savings, longer maintenance cycles, and a reduced environmental footprint is often undeniable. This is a crucial pivot in today’s shipping industry trends towards sustainability and pure efficiency.

Impact on Hull Performance and Fleet Efficiency

The ultimate goal? Hull performance optimization! A clean hull equals better hydrodynamics, which directly translates to superior fleet efficiency. Vessels with optimized hulls can go faster with less power, or maintain speed with way less fuel.

The silicone vs. biocide-based fouling release debate highlights this core difference: biocides deter, while silicones release. This can lead to varying levels of persistent fouling, with silicone generally offering a cleaner hull over a longer period, thus providing a more consistent boost to drag reduction technology and overall fleet efficiency.

The Future of Antifouling: Sustainability and Innovation

The future is clear: our maritime industry is steaming full speed ahead towards decarbonization and greater environmental responsibility. This absolutely champions eco-friendly antifouling solutions. Expect the focus on sustainable maritime solutions to only get stronger!

Innovation is constant. We’re seeing smarter, less harmful biocides and even tougher, higher-performing silicone formulations. Plus, imagine real-time hull performance monitoring with advanced sensors – optimizing everything and further slashing operational expenditure (OPEX)!

Yes, the choice between silicone vs. biocide-based fouling release will always consider your vessel’s unique profile, routes, and regulations. But let’s be honest: silicone’s compelling advantages in fuel efficiency, environmental benefits, and lifecycle costing make it an increasingly irresistible choice for anyone serious about green shipping initiatives and boosting their maritime ROI.

Conclusion

So, what’s the verdict? The decision between silicone and biocide-based fouling release strategies is nuanced. While biocides have a storied past, their environmental impact and tightening antifouling regulations are undeniably pushing the industry towards greener pastures. Silicone-based coatings, despite a potentially higher initial cost, deliver substantial long-term benefits: massive fuel consumption reduction, impeccable environmental compliance shipping, and significant savings in operational expenditure (OPEX), all thanks to their superior drag reduction technology and extended lifespan.

For maritime operators truly aiming for hull performance optimization and stellar ROI, a deep dive into lifecycle costing coatings isn’t just recommended – it’s essential. As the maritime sector charges towards sustainable maritime solutions and bold green shipping initiatives, the undeniable momentum is shifting towards non-toxic, super-efficient fouling release systems like silicone. This isn’t just a trend; it’s shaping the very future of marine coating selection and fleet efficiency!

![]()