Alkyd Marine Enamel: A Top Choice for Boat Maintenance

Your boat is a significant investment, constantly battling the elements. Choosing a paint is more than aesthetics; it’s about deploying the first line of defense to protect your asset.

Yes, Alkyd marine enamel is a top choice because it is a powerful, time-tested coating system specifically engineered to shield your investment from the harsh marine environment. More than just a layer of color, this paint forms a durable, protective barrier against sun, salt, and physical wear. Its reliability stems from a balanced formulation that provides excellent adhesion, flexibility, and weather resistance, ensuring your vessel not only looks great but is also fundamentally protected from corrosion and degradation. For any boat owner serious about maintenance, an alkyd enamel system offers a combination of performance, aesthetic appeal, and long-term value that is hard to beat.

![[Image Placeholder]> **Prompt:** A beautiful, well-maintained white and blue yacht anchored in a calm, turquoise bay, gleaming under the bright sun, showcasing its pristine condition. [Image Placeholder]> **Prompt:** A beautiful, well-maintained white and blue yacht anchored in a calm, turquoise bay, gleaming under the bright sun, showcasing its pristine condition.](https://jdmarinepaint.com/wp-content/uploads/2025/08/未命名设计-copy43-5.png)

This powerful protection is not just a single feature but a combination of robust qualities that work together to guard your boat. Let’s break down how this tough coating provides a shield against the elements.

What Makes Alkyd Marine Enamel a Powerful Shield Against the Elements?

The marine environment is relentless. Constant exposure to UV rays, corrosive salt spray, and the inevitable scuffs and scrapes of boating life can quickly break down an inferior coating. This leads to faded colors, cracking paint, and peeling films, which not only ruin your boat’s appearance but also expose the underlying structure to damaging rust and moisture. The constant worry and work required to fix these issues can take the joy out of ownership.

The protective power of alkyd marine enamel comes from a trifecta of robust qualities. This isn’t just paint; it’s a shield engineered to withstand the specific challenges of the sea. Its formulation is designed to provide tenacious adhesion and flexibility, creating a tough film that moves with your boat without cracking. This resilient foundation is then fortified with superior weather resistance, ensuring it stands up to the elements day after day, year after year, keeping your investment safe and sound.

These protective qualities are crucial, but a boat’s appearance is its calling card. Let’s look at how the system delivers a stunning finish.

A Triple Defense System

An effective marine enamel paint fights on three fronts to keep your vessel in top condition.

| Protective Quality | Why It Matters for Your Boat | The JDmarine Advantage |

|---|---|---|

| Superior Weather Resistance | The sun’s UV radiation fades color and breaks down the paint’s binder, while salt spray accelerates corrosion. A weather-resistant paint maintains its color and protective integrity for much longer. | Our alkyd enamels use high-quality pigments and resins formulated for excellent resistance to sun, wind, and salt, preventing premature degradation. |

| Unmatched Toughness | Docks, equipment, and foot traffic all cause scuffs and abrasion. The paint must be tough and wear-resistant to handle the physical demands of boating without chipping or scratching easily. | We engineer our coatings to cure into a tough, durable film that stands up to the daily wear and tear your boat endures. |

| Excellent Adhesion & Flexibility | A boat’s hull and superstructure are not rigid; they flex and vibrate. A paint that isn’t flexible will crack and peel, allowing water to get underneath. Strong adhesion is the foundation of all protection. | The inherent flexibility and superior bonding properties of our alkyd marine enamel ensure it stays firmly attached, flexing with the vessel to maintain a seamless, protective seal. |

How Does Alkyd Hull Enamel Enhance Your Boat’s First Impression?

The hull is the most visible part of your boat, and its condition makes an immediate statement. A dull, faded, or chalky finish can make even the most seaworthy vessel look neglected and old, diminishing its value and your pride of ownership. You need a coating that not only protects but also presents your investment in the best possible light.

Your boat’s first impression is everything, and the finish on the hull is what everyone sees. A high-quality Alkyd Marine Hull Enamel is engineered to provide a beautiful, long-lasting appearance. For instance, our JDC43-31 Alkyd Hull Paint is specifically formulated to deliver a bright, full, and vibrantly colored finish that dramatically boosts your boat’s visual appeal. But this stunning topcoat is more than just cosmetic. It serves as a hard-working protective layer for the hull and superstructure, shielding them from the elements while ensuring your vessel looks its absolute best, whether at the dock or on the open water.

While the hull gets the glory, the deck does the hard work. This high-traffic area requires a specialized solution.

Why is Alkyd Deck Enamel Considered a Workhorse Coating?

A boat’s deck isn’t just for show; it’s a functional, high-traffic work area. It endures constant foot traffic, dropped equipment, anchor chains, and cleaning an amount of punishment no other part of the boat sees. Using a standard hull paint on the deck is a mistake, as it will quickly scuff, chip, and wear away, leaving the surface unprotected and looking shabby.

The unique challenges of protecting a high-traffic deck demand a specialized coating. An Alkyd Marine Deck Enamel is the workhorse of any good paint system. It’s not just about color; it’s a dedicated anti-wear coating designed for extreme durability and toughness. Our JDC42-32 Alkyd Deck Paint is formulated to create a hard, wear-resistant surface that can handle constant foot traffic, shuffled equipment, and harsh cleaning without failing. It provides the essential grip and protection needed to keep your deck safe, functional, and looking good through an entire season of use.

Underpinning these tough topcoats is the most important battle of all: the war on rust.

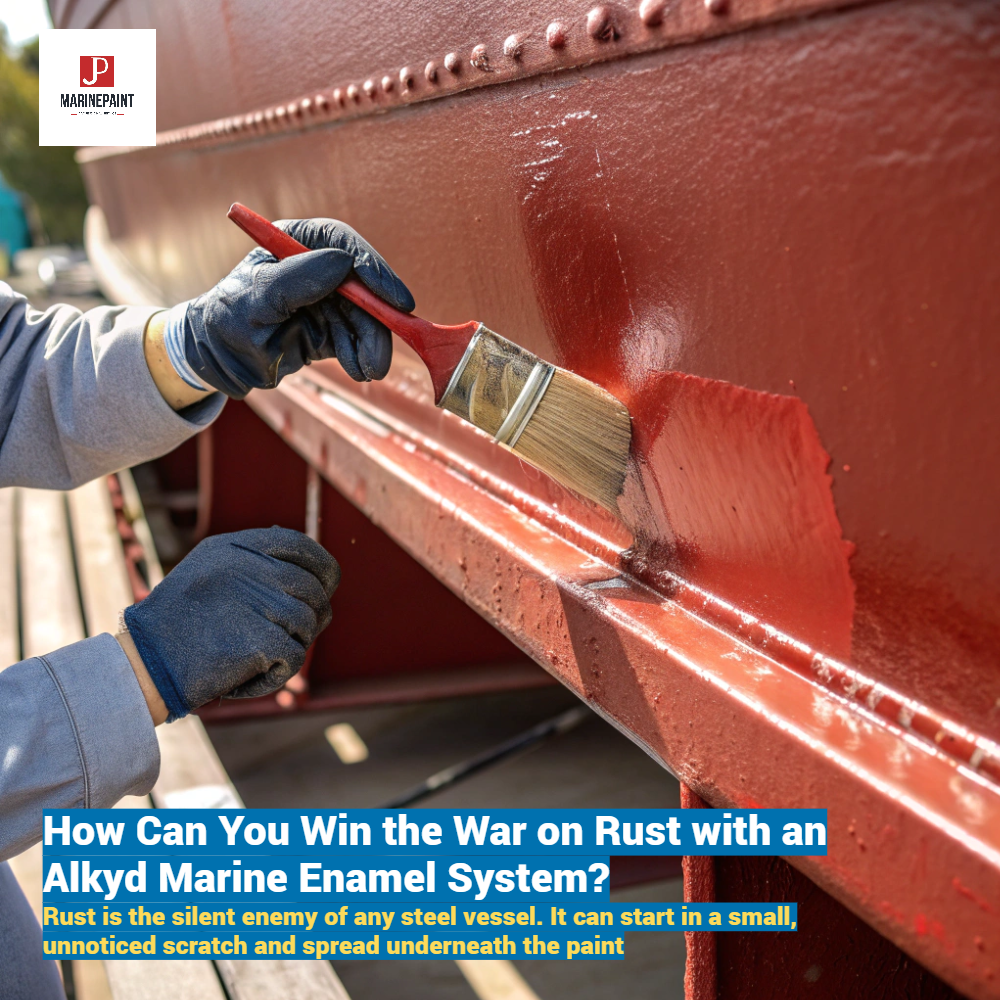

How Can You Win the War on Rust with an Alkyd Marine Enamel System?

Rust is the silent enemy of any steel vessel. It can start in a small, unnoticed scratch and spread underneath the paint, compromising the structural integrity of your investment. Simply covering it with a topcoat is a temporary fix that traps moisture and can make the problem worse. Winning this war requires a proactive strategy that stops corrosion before it can begin, preserving the very foundation of your boat.

The fight against corrosion is the most critical aspect of proper boat maintenance, and it starts with the right foundation. Your beautiful topcoat can’t do its job if the steel underneath is failing. Alkyd Marine Anti-Rust Primers are the unsung heroes of the paint system. They are chemically engineered to create a powerful, adhesive barrier on the steel that blocks moisture and salt, preventing rust from ever taking hold. These primers are formulated with special anti-rust pigments that actively inhibit corrosion. Products like our JDC53-37 Zinc Grey Alkyd Anti-Rust Paint stop corrosion before it can start, preserving the strength and integrity of your vessel from the inside out.

Investing in this complete system upfront leads to significant savings in the long run.

How Does Quality Alkyd Marine Enamel Provide Long-Term Value?

Boat maintenance can feel like a never-ending cycle of expenses. Cutting corners with cheap paint seems like a way to save money now, but it’s a costly mistake. Inferior coatings fail quickly, forcing you into a frustrating loop of scraping, sanding, and repainting. This not only wastes your valuable time but also leaves your boat vulnerable to rust, which can lead to staggeringly expensive structural repairs.

True long-term value comes from investing in a high-quality system from the start. Choosing the right alkyd marine enamel system is the single most important factor in cost-effective maintenance. A durable, properly applied alkyd coating simply lasts longer, significantly extending the time between repaints. This saves you money on materials and labor and gives you more time to actually enjoy your boat. More importantly, by protecting the underlying steel from rust with a robust primer and topcoat system, you prevent the need for far more costly structural work down the road. It’s a smart investment that pays for itself by protecting your primary investment: your boat.

Still have questions? Let’s address some of the most common ones from fellow boat owners.

Have More Questions About Protecting Your Investment with Alkyd Marine Enamel?

Here are answers to a few common questions we get from boat owners who are serious about maintenance.

Is alkyd marine enamel difficult for a DIYer to use?

No, it’s actually one of the more user-friendly marine coatings. High-quality formulas have good "application performance," which means they are designed to flow evenly and can be applied well with a brush or roller. For dedicated boat owners who follow the instructions, it’s a very accessible system for achieving a professional-looking finish. For safety, always be sure you are handling marine coatings safely.

How can I guarantee my paint job will last?

The single most important factor is surface preparation. The paint can only perform as designed if it can bond directly to a clean, stable surface. You must start with a surface that is completely clean, dry, and free of all rust, oil, and grease. Taking the time to do this crucial first step right is the key to a long-lasting, durable finish.

Do I really need a separate primer, deck paint, and hull paint?

Yes, for the best and most durable protection, you absolutely do. Using a complete system is the core of proper boat maintenance. Each product is formulated for a specific job: the primer is for rust prevention and adhesion to steel, the deck paint is for extreme wear and tear, and the hull paint is for weather resistance and a beautiful finish. Using them together ensures every part of your boat gets the specialized protection it needs.

Conclusion

A complete alkyd marine enamel system is a wise, cost-effective choice that protects your boat’s value, appearance, and structural integrity for years to come—a smart decision for a lasting investment.

Related Articles:

What is the Technical Breakdown of an Alkyd Marine Enamel Paint System?

Is Alkyd Marine Enamel the Right Choice for Your Vessel’s Protection?

![]()