Safeguarding Assets: The Power of Offshore Heavy-Duty Anti-Corrosion Coatings

The offshore environment is a relentless adversary, constantly threatening vital infrastructure with the corrosive forces of nature. Ignoring this challenge is not an option; Offshore Heavy-Duty Anti-Corrosion Coatings are an essential investment, providing the ultimate defense for asset protection.

For investors and operators, these engineered solutions are not merely paints; they are a strategic imperative for enhanced safety, longevity, and superior financial returns. Robust anti-corrosion solutions are absolutely critical for driving long-term value in offshore engineering, safeguarding against the immense costs of corrosion. They are the frontline defense for structures in extreme environments, ensuring the operational integrity and extending the lifespan of critical assets.

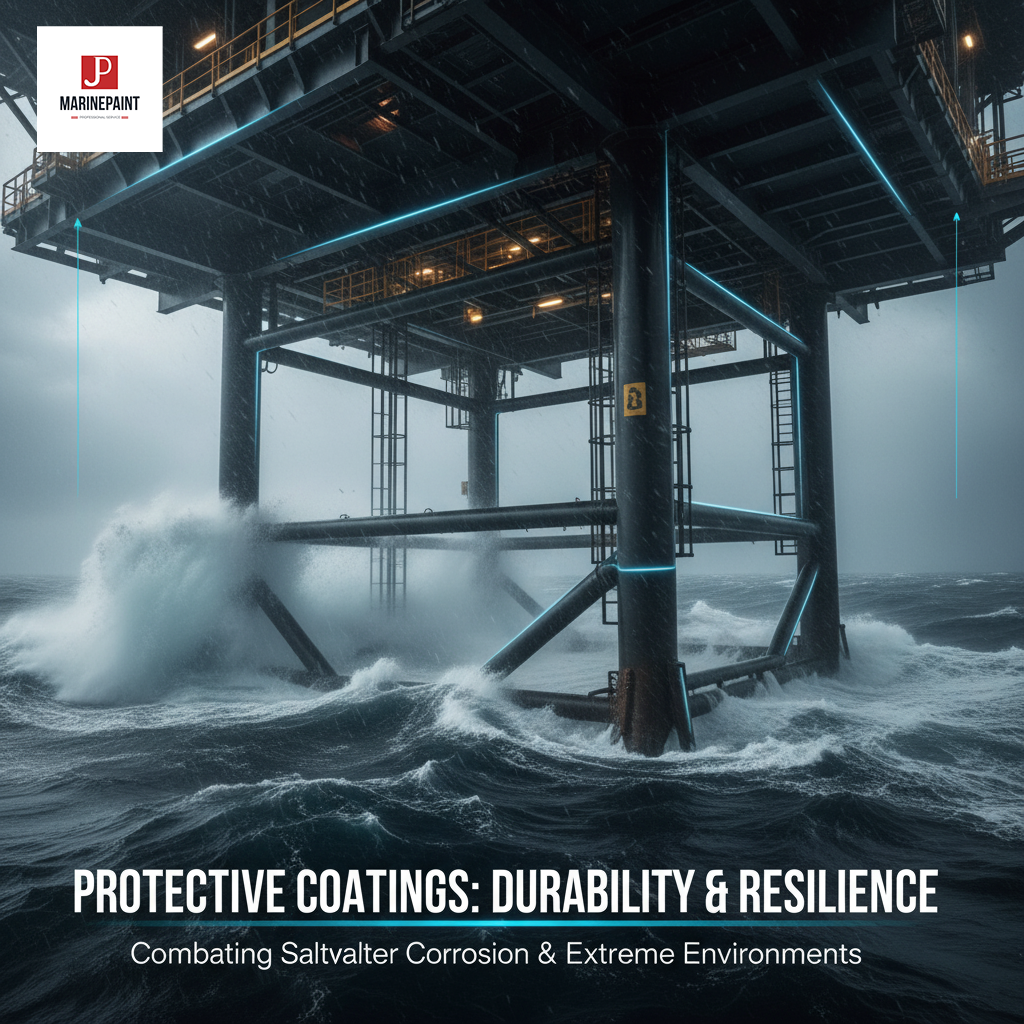

![[Image Placeholder]**Image Title:** Enduring the Storm: Offshore Heavy-Duty Anti-Corrosion Coatings in Action**Image Description:** A powerful image of a robust offshore oil rig or wind turbine structure, partially shrouded in sea spray and dramatic lighting, symbolizing the harsh environment. The visible parts of the structure should appear meticulously coated, with a subtle glow around the protective layer, conveying resilience and advanced protection against marine corrosion.**Image Prompt:** A dynamic, digitally stylized image of a modern cargo ship sailing smoothly on a calm sea. Overlay futuristic glowing lines and upward-trending bar graphs around the ship, representing [Image Placeholder]**Image Title:** Enduring the Storm: Offshore Heavy-Duty Anti-Corrosion Coatings in Action**Image Description:** A powerful image of a robust offshore oil rig or wind turbine structure, partially shrouded in sea spray and dramatic lighting, symbolizing the harsh environment. The visible parts of the structure should appear meticulously coated, with a subtle glow around the protective layer, conveying resilience and advanced protection against marine corrosion.**Image Prompt:** A dynamic, digitally stylized image of a modern cargo ship sailing smoothly on a calm sea. Overlay futuristic glowing lines and upward-trending bar graphs around the ship, representing](https://jdmarinepaint.com/wp-content/uploads/2025/09/enduring-the-storm-offshore-heavy-duty-anti-corrosion-coatings-in-action.png)

Let’s explore how these specialized coatings stand up to the extreme challenges of the marine world, translating into profound benefits for asset integrity and operational prosperity.

The Extreme Challenge: Understanding Corrosion in Offshore Environments?

Do you truly grasp the relentless assault your offshore assets face daily? Corrosion offshore is far more complex than simple rust, posing a multifaceted threat that can swiftly compromise structural integrity and financial stability.

Defining offshore corrosion means understanding its diverse forms: atmospheric corrosion from salt-laden air, immersion corrosion in constantly submerged areas, and the particularly aggressive splash zone corrosion where structures battle daily wetting and drying cycles. Beyond these, specific mechanisms like galvanic corrosion, pitting, crevice corrosion, and even stress corrosion cracking relentlessly attack materials. For a deeper dive into the technical aspects of marine corrosion, consider exploring AMPP (NACE) Resources on Marine and Offshore Corrosion. Factors accelerating corrosion offshore are numerous: high salinity, constant moisture, relentless wave action, intense UV radiation, extreme temperature fluctuations, and even chemical exposure and microbiologically influenced corrosion (MIC) further compound the problem. The cost of inaction is dire, leading to severe safety hazards, crippling downtime, and immense financial losses without adequate Offshore Heavy-Duty Anti-Corrosion Coatings. This demands heavy-duty marine paint solutions and effective marine corrosion prevention strategies to withstand these extreme conditions.

The Power of Offshore Heavy-Duty Anti-Corrosion Coatings: A Foundation for Durability?

What makes some structures endure decades in the harshest seas while others falter? The answer lies in the strategic deployment of Offshore Heavy-Duty Anti-Corrosion Coatings, engineered solutions designed to forge a foundation for unparalleled durability.

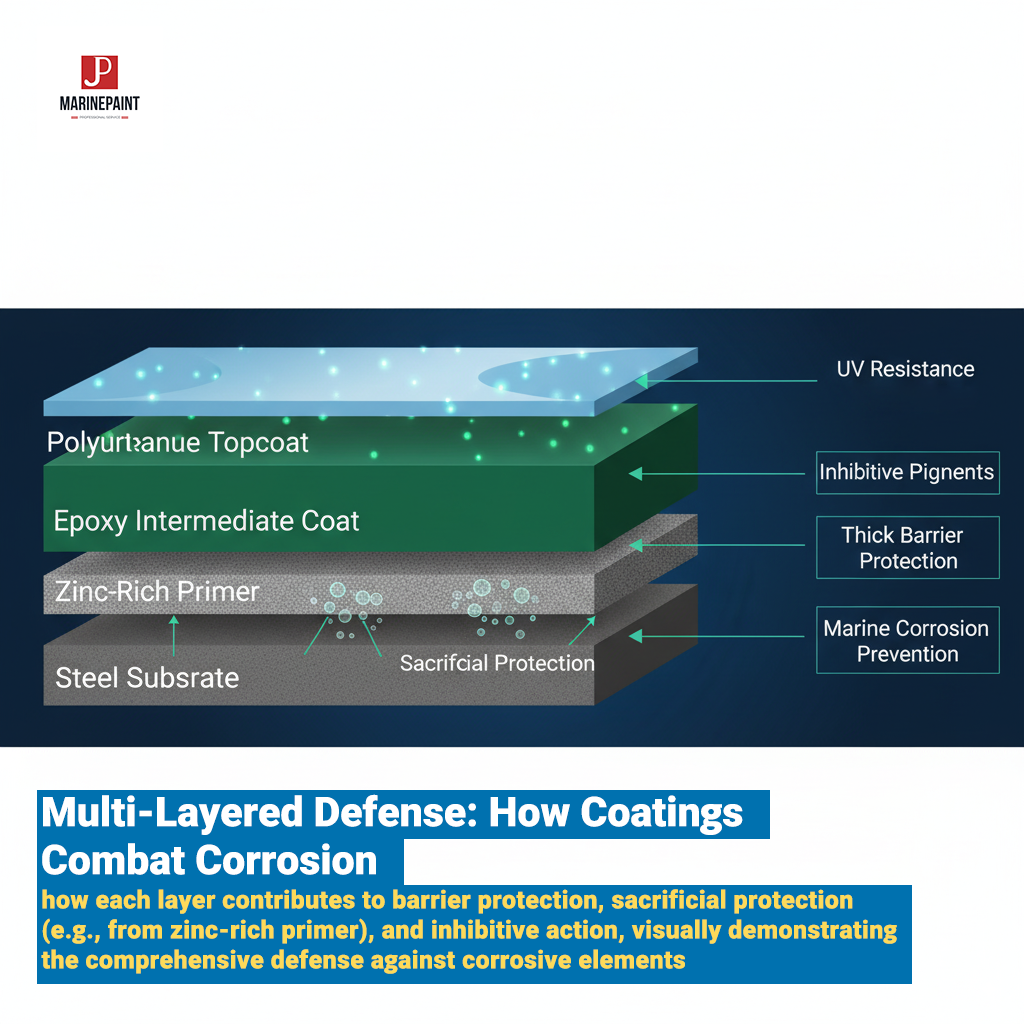

Offshore Heavy-Duty Anti-Corrosion Coatings are not standard paints; they are sophisticated, multi-layered systems meticulously engineered to thrive in extreme conditions. Their prowess in providing superior corrosion protection for offshore assets stems from a combination of mechanisms. Firstly, they act as barrier protection, physically isolating the substrate from corrosive elements like saltwater, oxygen, and chemicals. Secondly, many systems, particularly those incorporating JDmarine’s robust JDH06-4 Epoxy Zinc-Rich Anti-Rust Primer, offer sacrificial protection; the zinc preferentially corrodes, protecting the underlying steel through galvanic action. Thirdly, certain coatings utilize inhibitive pigments that chemically interfere with corrosion processes, actively neutralizing corrosive agents. Together, these layers form an impenetrable shield, crucial for offshore structure protection and ensuring asset integrity management.

This meticulous approach ensures that drilling platforms, FPSOs, and offshore wind turbine foundations are not just protected, but fortified against the relentless forces that seek to degrade them. It’s about building a defense that lasts.

Extending Service Life: The Foremost Benefit of Offshore Heavy-Duty Anti-Corrosion Coatings?

Are you consistently battling premature asset degradation and the looming threat of costly replacements? The most compelling advantage of Offshore Heavy-Duty Anti-Corrosion Coatings is their remarkable ability to extend the service life of your most valuable assets, transforming operational lifecycles and financial forecasts.

These advanced coating systems provide a significant extension of asset lifespan across a vast range of offshore infrastructure, including drilling platforms, FPSOs (Floating Production Storage and Offloading units), jack-up rigs, subsea pipeline coatings, and critical subsea equipment. Furthermore, they are indispensable for offshore wind turbine foundations and topside structures, as well as essential port facilities and marine terminals. By preserving structural integrity, these coatings prevent material degradation and fatigue, ensuring long-term performance under the extreme stresses of the marine environment. The direct impact on investment ROI is profound; maximizing asset utility and deferring capital expenditure (CAPEX) with advanced Offshore Heavy-Duty Anti-Corrosion Coatings translates directly into increased profitability and a stable asset value for years to come. This is critical for asset life extension and heavy-duty marine paint solutions. For comprehensive guidance on managing corrosion in offshore assets, refer to DNV Recommended Practices for Offshore Corrosion Management.

Optimized Maintenance & Reduced OPEX: The Economic Advantage of Anti-Corrosion Coatings?

Are frequent, complex, and costly maintenance interventions draining your operational budgets? The strategic deployment of Offshore Heavy-Duty Anti-Corrosion Coatings offers a powerful economic advantage, fundamentally restructuring maintenance frequencies and significantly reducing operational expenditure (OPEX).

These high-performance coatings excel at minimizing maintenance frequency and costs. By providing a durable barrier, they dramatically reduce the need for constant surface preparation and re-coating, especially in aggressive areas like the splash zone protection. This means fewer emergency repairs and avoided costly downtime incidents, which can rapidly escalate in an offshore context. This leads directly to lowering operational expenditure (OPEX) by saving on labor, materials, and the specialized equipment required for repair operations in remote maritime locations. Reduced logistic costs associated with offshore maintenance further compound these savings. Integrating Offshore Heavy-Duty Anti-Corrosion Coatings into a comprehensive asset integrity management program allows for strategic planning, enabling more predictable budgets and enhancing overall financial control through effective corrosion control strategies.

Enhancing Operational Safety and Asset Value with Superior Coatings?

Is the threat of structural failure a constant concern for your offshore operations? Beyond protecting your bottom line, superior Offshore Heavy-Duty Anti-Corrosion Coatings play a critical role in mitigating safety risks and safeguarding the inherent value of your offshore assets.

These coatings are instrumental in mitigating safety risks by preventing structural failures and component degradation that could lead to catastrophic incidents. They are vital for ensuring personnel safety and maintaining rigorous regulatory compliance within the offshore environment. Moreover, investing in high-quality coatings ensures the continuous protection of asset value and market competitiveness. By maintaining the pristine condition and aesthetics of offshore infrastructure, these coatings directly contribute to increasing resale value and extending charter opportunities. Our JD908 Acrylic Polyurethane Topcoat Non-Yellowing Resistant provides not only exceptional durability but also maintains a vibrant finish, enhancing visual appeal. Compliance with industry standards and regulations, supported by robust Offshore Heavy-Duty Anti-Corrosion Coatings, is also crucial for successful certification and audits, reinforcing overall asset integrity management and offshore safety standards. For broader industry insights on these critical areas, consult the OGP Guidelines on Asset Integrity and Offshore Safety.

Key Types and Systems of Offshore Heavy-Duty Anti-Corrosion Coatings?

Navigating the array of anti-corrosion coating technologies can be complex. Which system offers the best protection for your specific offshore challenge? Understanding the key types and systems of Offshore Heavy-Duty Anti-Corrosion Coatings is essential for optimal asset protection.

Epoxy systems are foundational to heavy-duty protection, known for their high build, excellent adhesion, and superior chemical resistance. Zinc-rich epoxies, like JDmarine’s JDH819 Epoxy Zinc Phosphate Primer, are typically used as primer layers, providing active sacrificial protection. High-solid epoxies serve as intermediate and topcoats, building substantial barrier protection. Polyurethane coatings (PU), such as aliphatic PUs, are often applied as topcoats in atmospheric zones for their superior UV stability, abrasion resistance maritime, and aesthetic appeal. Specialized coatings for specific offshore applications further enhance protection: anti-foulings are critical for immersed zone coatings, while passive fire protection (PFP) coatings are vital for safety-critical areas, and elastomeric coatings offer flexibility and impact resistance. Understanding coating specifications is paramount, ensuring you match the right Offshore Heavy-Duty Anti-Corrosion Coatings to the unique demands of each offshore environment, from atmospheric corrosion zones to subsea pipeline coatings.

Strategic Selection and Application Considerations for Offshore Heavy-Duty Anti-Corrosion Coatings?

Even the highest quality Offshore Heavy-Duty Anti-Corrosion Coatings will fail without proper execution. Are you aware of the critical steps required to ensure these advanced systems deliver their promised longevity and performance?

The importance of thorough surface preparation cannot be overstated. Abrasive blasting to standards like SA 2.5 ensures optimal surface cleanliness and roughness, which is fundamental for achieving optimal adhesion for long-term performance. Without this crucial first step, even the best coatings are compromised. This must be followed by expert application and rigorous quality control. Qualified personnel must strictly adhere to specifications and application parameters. Inspection protocols, including dry film thickness (DFT) inspection and adhesion testing coatings, are vital to verify the integrity of each layer. Furthermore, environmental impact and sustainable coating solutions are increasingly important, with a focus on low VOC coatings and eco-friendly formulations that comply with stringent regulatory compliance marine for offshore construction. Investing in marine painting contractors with proven expertise in industrial coating applications is key.

Conclusion: Investing in Offshore Heavy-Duty Anti-Corrosion Coatings for Lasting Prosperity

Robust anti-corrosion solutions are absolutely indispensable in the challenging offshore realm. Secure your offshore investments with engineered Offshore Heavy-Duty Anti-Corrosion Coatings for optimal performance and profitability.

FAQs on Offshore Heavy-Duty Anti-Corrosion Coatings

Q1: How long do offshore heavy-duty anti-corrosion coatings typically last in extreme environments?

A1: With correct coating selection and skilled application, offshore heavy-duty anti-corrosion coatings can last from 10 to 25+ years. Factors like the specific coating system type, application quality, and the precise harshness of the offshore environment (e.g., splash zone vs. deep immersion) all play a role in coating longevity offshore.

Q2: What is the most critical factor for the longevity of offshore anti-corrosion coatings?

A2: The most critical factor is thorough surface preparation, such as abrasive blasting to industry standards like SA 2.5. This ensures optimal adhesion. Following this, correct coating selection for the specific zone and expert, compliant application are equally vital for ensuring durable offshore structure protection.

Q3: Are eco-friendly offshore heavy-duty anti-corrosion coatings as effective as traditional ones?

A3: Yes, advancements in sustainable formulations, often low VOC coatings, now meet or even exceed the performance benchmarks of traditional systems. Driven by regulatory demands and industry innovation, these eco-friendly options offer excellent marine corrosion prevention without compromising heavy-duty protection.

Q4: How does offshore heavy-duty anti-corrosion coating maintenance differ for splash zones vs. submerged areas?

A4: Splash zones require coatings with superior abrasion resistance maritime and impact resistance coatings due to constant wave action; maintenance often involves challenging rope access. Submerged areas require coatings tolerant of constant immersion and may involve ROVs or divers for inspection and repair, ensuring effective subsea pipeline coatings and FPSO corrosion control.

Q5: What initial investment is required for high-quality offshore heavy-duty anti-corrosion coatings compared to the long-term savings?

A5: While the initial capital expenditure (CAPEX) for high-quality offshore heavy-duty anti-corrosion coatings can be significant, the return on investment through reduced maintenance (OPEX reduction), extended asset life, avoided downtime, and enhanced offshore safety standards far outweighs this over the asset’s lifecycle.

Q6: How do regulatory bodies impact the choice of offshore heavy-duty anti-corrosion coatings?

A6: Regulatory bodies mandate compliance with international standards (e.g., ISO), regional environmental regulations concerning VOC emissions or biocides, and classification society requirements. These stringent guidelines directly influence coating specification development and selection, ensuring safe and environmentally responsible offshore construction.

![]()