Corrosion and contamination in potable water tanks threaten crew health. Unsuitable coatings can release harmful substances, with unthinkable consequences. Choosing a certified, specialized coating is the only way to guarantee drinking water safety.

A marine potable water tank is a critical facility for storing the crew’s daily drinking water, and the choice of its internal coating is directly related to water quality and crew health. To ensure drinking water safety, it is essential to use a specially designed and certified, non-toxic, and non-polluting potable water tank coating. Such coatings, like solvent-free epoxies, form a strong, smooth, and odorless protective film on the tank walls, effectively preventing metal corrosion, bacterial growth, and secondary water contamination. For example, JDH912 Epoxy Potable Water Tank Coating is a two-component, solvent-free polyamine-cured epoxy coating designed specifically for potable water tanks . Selecting a food-grade coating that meets international standards and strictly following application and maintenance specifications are core to safeguarding the purity and safety of this onboard "lifeline."

![[Image Placeholder: A clear image showing the clean, coated interior of a marine potable water tank.] [Image Placeholder: A clear image showing the clean, coated interior of a marine potable water tank.]](https://jdmarinepaint.com/wp-content/uploads/2025/06/a-clear-image-showing-the-clean-coated-interior-o-2.png)

To understand why potable water tank coatings are so important and how to correctly select, apply, and maintain them to provide the most reliable drinking water protection for the crew, continue reading this guide.

Why is the Choice of Marine Potable Water Tank Coatings So Crucial?

Problem: Thinking any anti-rust paint can be used for a potable water tank? This misconception could lead to chemicals from the coating leaching into the precious water source.

Agitate: Imagine the crew consuming water contaminated by substandard coatings over the long term; their health would be insidiously and severely threatened. This not only violates maritime safety regulations but is also a gross irresponsibility toward the crew’s well-being. In the long run, the cost of tank corrosion and rework due to coating failure is far greater than the initial investment in a qualified, specialized coating.

Solution: Using a food-grade coating specially designed and certified by authoritative bodies is the only way to avoid this catastrophic outcome. These coatings undergo rigorous testing to ensure they do not release any harmful substances under long-term immersion, forming a stable and reliable physical barrier that protects the purity and safety of the drinking water from the source.

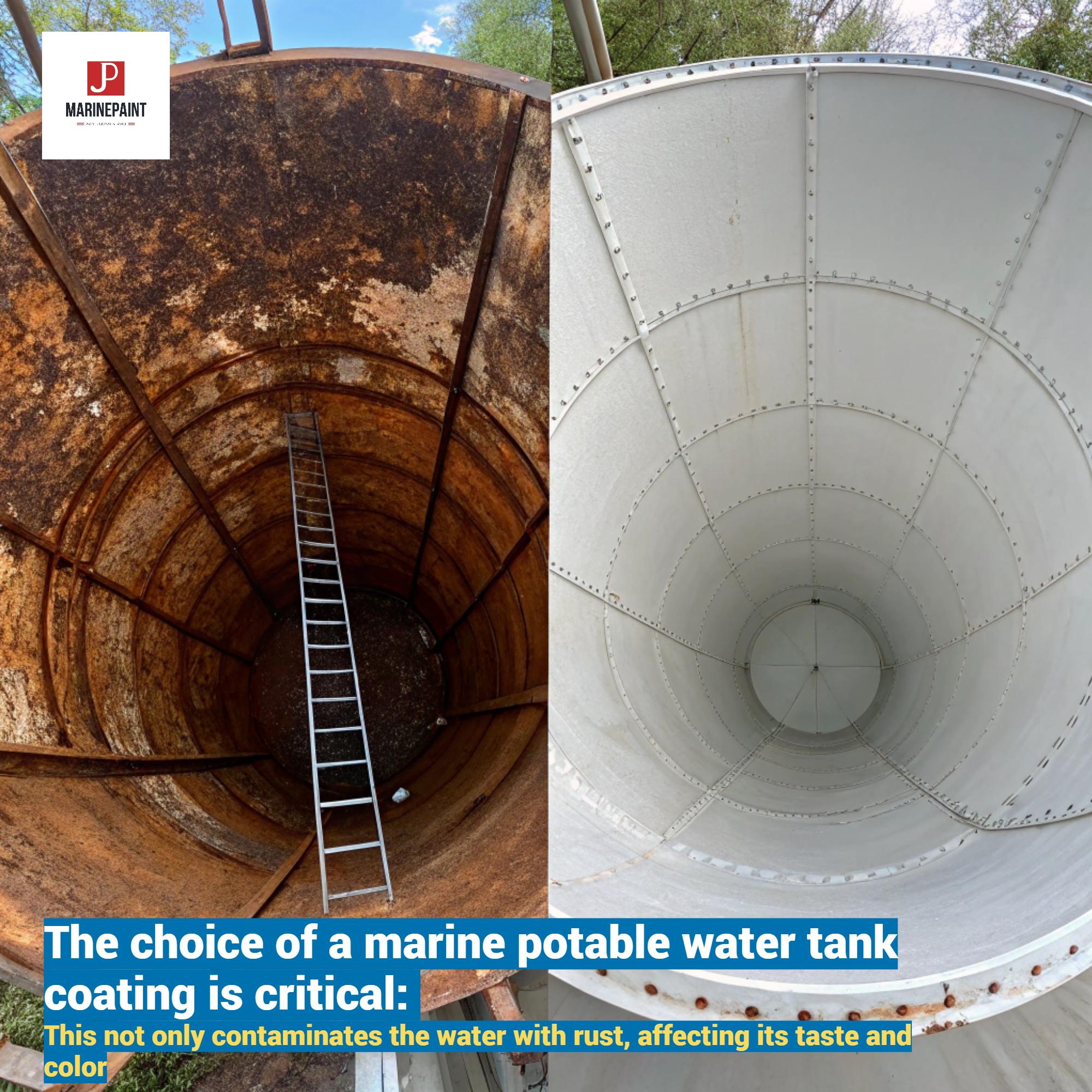

The choice of a marine potable water tank coating is critical because it forms the first and most important line of defense in ensuring drinking water safety. In the marine environment, potable water tanks are in constant contact with water. Without an effective protective coating, the steel structure will inevitably corrode. This not only contaminates the water with rust, affecting its taste and color, but can also compromise the tank’s structural integrity, posing a safety hazard.

More seriously, common industrial coatings that are not qualified may contain harmful substances like solvents, heavy metals, or plasticizers. Under long-term immersion, these substances can slowly leach into the drinking water, causing long-term and irreversible damage to the crew’s health. Therefore, international maritime regulations and health standards explicitly require that the interior of potable water tanks must be coated with specialized, food-grade certified coatings.

Key Risks in Potable Water Tanks and How Coatings Provide Solutions

| Risk Category | Manifestation | Solution Provided by Specialized Coatings |

|---|---|---|

| Chemical Contamination | Harmful substances like solvents and heavy metals from common paints leach out, contaminating the water source. | Use a solvent-free formula like JDH912 Epoxy Potable Water Tank Coating to eliminate the risk of chemical migration from the source [12]. |

| Physical Contamination | Rust from the corrosion of the tank’s steel walls enters the water. | Forms a dense, tough protective film that completely isolates the water from the steel substrate, providing long-lasting corrosion protection [19]. |

| Biological Contamination | Rough or defective coating surfaces can easily harbor bacteria and biofilm. | Provides a smooth, non-porous surface that resists dirt adhesion and is easy to clean, thus inhibiting microbial growth. |

| Structural Damage | The steel structure of the potable water tank thins due to corrosion, reducing its strength. | Excellent adhesion and water resistance ensure the coating effectively protects the steel structure for the long term, extending the service life of the tank [13]. |

Therefore, investing in a high-quality, specialized potable water tank coating is not only a commitment to the crew’s health but also a wise protection of the vessel’s assets.

Which Type of Coating is the Ideal Choice for Marine Potable Water Tanks?

Problem: The market is flooded with coatings, from alkyd paints to polyurethane paints. How can you tell which is truly suitable for the harsh environment of direct contact with drinking water?

Agitate: Choosing the wrong type is not just a waste of money; more frighteningly, it may lack the necessary water resistance, non-toxicity, and long-term durability. If the coating fails prematurely underwater, it means emptying the tank, re-preparing the surface, and repainting. This leads to vessel downtime, high repair costs, and operational losses, all while the crew’s drinking water safety is put at risk.

Solution: Only by deeply understanding and selecting a coating designed for potable water tanks can you achieve long-lasting, safe protection. Currently, the industry’s recognized best choice is a high-performance, two-component solvent-free epoxy coating, which strikes a perfect balance in safety, durability, and application performance.

For marine potable water tanks, the ideal coating is a two-component, solvent-free epoxy coating [12]. This type of coating has become the top choice for protecting drinking water safety due to its outstanding comprehensive performance.

First, being "solvent-free" is one of its core advantages. This means that during the formulation and curing process, there are almost no volatile organic compounds (VOCs) released. This is not only friendlier to the applicators and more environmentally responsible but most importantly, it eliminates the fundamental risk of residual solvents migrating into and contaminating the drinking water [12].

Second, the film formed after the epoxy resin cures has excellent physical properties. It is tough, dense, and has a smooth surface, capable of resisting long-term water immersion without softening or degrading, while also preventing the adhesion and growth of bacteria and microorganisms [14]. Its excellent adhesion and chemical resistance ensure that the coating adheres firmly to various shipbuilding materials like carbon steel, stainless steel, or galvanized steel, providing durable and reliable corrosion protection [25].

JDH912 Epoxy Potable Water Tank Coating is a prime example of such a product. As a versatile lining coating designed for the marine sector, it is not only suitable for potable water tanks but also for greywater and crude oil tanks, demonstrating its broad resistance to various media [12].

[Image Placeholder: A product shot of the JDH912 Epoxy Potable Water Tank Coating cans, with a sample of its smooth, white cured film displayed next to them.]

How to Identify a Qualified Potable Water Tank Coating?

- Check the Product Description: It should be clearly labeled as "Potable Water Tank Coating" or have a similar specified use [12].

- Confirm the Product Type: Prioritize "solvent-free epoxy coating" types [12].

- Request Certification Documents: The supplier should be able to provide relevant food-grade safety certifications or third-party test reports, proving compliance with international standards for materials in contact with drinking water.

- Review Technical Data: Pay attention to key parameters such as volume solids (solvent-free types are typically very high, e.g., JDH912 is 98±2%), and recommended dry film thickness [25].

Never use any standard alkyd anti-rust paints [23], hull paints [5], or deck paints [26] for the interior of potable water tanks, as their design purpose and chemical composition are completely unsuitable for an environment in direct contact with drinking water.

How to Correctly Apply Marine Potable Water Tank Coatings for Optimal Results?

Problem: Even with a top-tier potable water tank coating, improper application will cause the coating to blister and peel, rendering all efforts and investments futile.

Agitate: From negligence in surface preparation to minor errors in mixing ratios and improper curing times, a mistake at any stage can lead to premature failure of the protective system, once again exposing the water quality to direct risks of corrosion and contamination. Rework is not only extremely expensive and time-consuming but will also severely impact the vessel’s operational schedule.

Solution: Adhering to strict, quantifiable application specifications is the only way to ensure the coating performs to its maximum protective potential. In a successful coating project, 70% of the success depends on surface preparation, and 30% on the application itself. Only with meticulous attention to every step can a perfect, long-lasting protective coating be achieved.

Correct application is the key to guaranteeing the performance of a marine potable water tank coating. It is not a simple painting job but a systematic process, primarily involving rigorous surface preparation and precise application.

Step 1: Thorough Surface Preparation

This is the most crucial part of the entire coating job. To ensure long-lasting adhesion of the subsequent coating, all surfaces to be coated must be clean, dry, and free of contaminants [25].

- For Carbon Steel: The recommended minimum standard is abrasive blast cleaning to Sa 2½ (ISO 8501-1). This standard requires the removal of all visible oil, grease, dirt, mill scale, rust, and old paint, with any remaining contaminants appearing only as slight stains in the form of spots or stripes. The process should create a sharp, angular profile for optimal mechanical adhesion [25].

- For Galvanized or Stainless Steel: These surfaces also require light sweep blasting with non-metallic abrasives or mechanical abrading to achieve a clean, rough, and uniform surface, ensuring there are no smooth areas [25].

- Cleaning: After blasting or grinding, all dust and debris must be thoroughly removed using a vacuum cleaner or clean, oil-free compressed air [5].

Step 2: Precise Coating Mixing and Application

| Application Stage | Key Points and Parameters (using JDH912 as an example) |

|---|---|

| Mixing Ratio | Mix strictly according to the volume ratio specified in the product data sheet. The mixing ratio for JDH912 is 2 parts Component A to 1 part Component B by volume [25]. |

| Induction Time | After mixing, two-component epoxy paints need to stand for a period to allow the initial reaction to begin. This is known as induction or pot life. The induction time for JDH912 at 23°C is 10 minutes [14]. |

| Application Method | Airless spray is the recommended primary method, as it can efficiently achieve the specified high film thickness [25]. Brush application is recommended for stripe coating and small repairs, but care must be taken to achieve the specified film thickness [25]. Roller application is only suggested for very small areas like freeing ports [25]. |

| Film Thickness | The application must achieve the recommended dry film thickness (DFT). As a tank coating, the typical DFT range for JDH912 is 150-500 microns [25]. |

| Application Conditions | The substrate temperature must be at least 3°C above the dew point to avoid condensation, which would affect adhesion [16]. |

Step 3: Sufficient Curing

After application, the coating must be given adequate time to fully cure before the tank can be filled with water. Curing time is significantly affected by temperature. For example, JDH912 requires 7 days to fully cure for immersion service at 23°C, but this extends to 15 days at 10°C [14].

How to Effectively Maintain and Inspect Marine Potable Water Tank Coatings?

Problem: Is the coating a "set it and forget it" system after application? If routine maintenance and inspection are neglected, minor physical damage or the unnoticeable accumulation of contaminants can gradually compromise the coating’s integrity.

Agitate: A pinhole-sized breach could become the starting point for corrosion across the entire tank wall. Biofilm formation will continuously affect water quality and can even clog pipelines. Dealing with the problem only after it becomes severe is not only costly to repair, but during that time, the crew’s drinking water safety has already been under a long-term potential threat.

Solution: Establishing and executing a simple, regular maintenance and inspection plan is key to the long-term safety of the potable water tank. Through a strategy of "prevention first, combined with remediation," issues can be addressed at an early stage, maintaining optimal protection at minimal cost and ensuring safe drinking water throughout the voyage.

Effective maintenance of the potable water tank coating is a necessary measure to ensure a continuous supply of safe drinking water and to protect the initial high-cost investment in the coating system. Maintenance work should be institutionalized and integrated into the vessel’s routine management and dry-docking plans.

Regular Inspection Checklist

- Timing: A comprehensive internal inspection is recommended each time the tank is scheduled to be emptied or at least during every dry-docking period [5].

- Inspection Points:

- Coating Integrity: Carefully check the internal walls for any signs of blistering, cracking, peeling, rust spots, or mechanical damage from external forces.

- Cleanliness: Check the tank bottom and corners for any sediment like sand or rust. Touch the inner walls to feel for any slimy biofilm (i.e., algae slime).

- Ancillary Structures: Inspect the coating on manholes, ladders, and pipelines, as these are often the starting points for corrosion.

Cleaning and Maintenance Guide

-

Routine Cleaning:

- Cleaning should be performed when sediment or biofilm is found during an inspection.

- The preferred method is high-pressure fresh water washing (around 2000 psi), which can effectively remove most salts, loose dirt, and biofilms.

- For stubborn deposits, a soft-bristled brush can be used for physical scrubbing. Tools that can severely scratch the coating, such as wire brushes, are strictly forbidden [5].

- After cleaning, the tank must be thoroughly rinsed with plenty of fresh water, then completely drained and dried.

-

Damage Repair:

- Localized coating damage found during inspection should be repaired promptly to prevent the spread of corrosion.

- The repair area must be prepared according to the surface preparation standards mentioned earlier, ground to St3 or better, and all grease and dirt must be removed [5].

- Touch up with the same type of potable water tank coating used originally, ensuring the specified film thickness is achieved.

-

Precautions:

- Prohibition of Unauthorized Chemicals: Any chemical cleaners or disinfectants must be confirmed to be compatible with the epoxy coating; otherwise, they may cause the coating to soften or fail.

- Ventilation and Safety: Before entering the tank for any work, ensure adequate ventilation and comply with all safety procedures for confined space entry [4].

Through such a systematic maintenance process, the service life of the potable water tank coating can be significantly extended, ensuring every drop of drinking water is safe and pure throughout the voyage.

Conclusion:

The safety of a marine potable water tank is vital to the crew’s health and life. Choosing certified coatings, adhering to professional application standards, and performing regular maintenance are the cornerstones of protecting this "lifeline," and the most fundamental responsibility to the crew.

![]()