How to Calculate Marine Paint Project Cost?

Budget overruns in the maritime industry are a constant threat. Your project’s first line of defense is moving beyond vague estimates to precise, reliable cost calculations for your marine paint project.

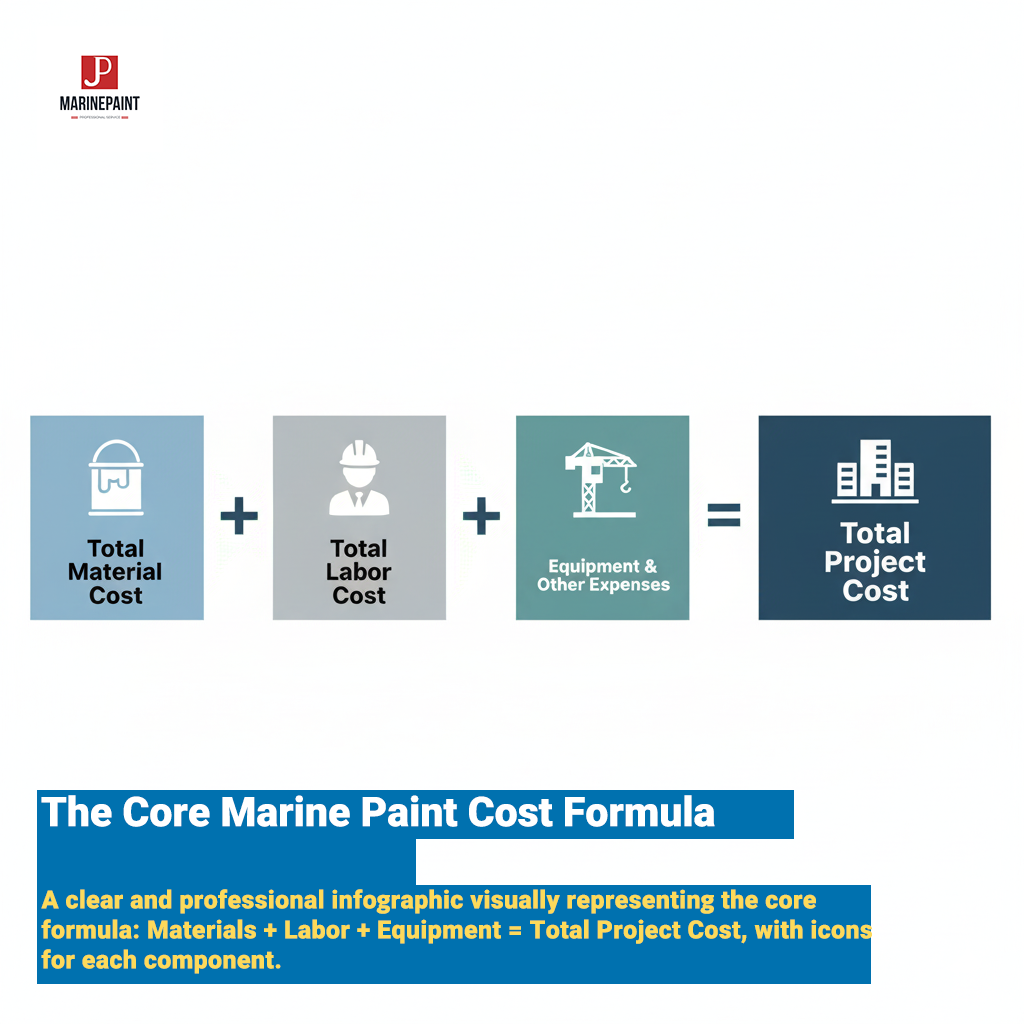

To accurately calculate your marine paint project cost, you must adopt a comprehensive formula: Total Project Cost = Total Material Cost + Total Labor Cost + Equipment & Other Expenses. Total Material Cost is determined by calculating the paint volume needed (Total Surface Area ÷ Practical Spreading Rate × Number of Coats) and multiplying it by the price per unit for each product in the coating system (primers, antifouling, topcoats). Total Labor Cost is the sum of man-hours for all surface preparation and application tasks, multiplied by the applicable hourly labor rate. Finally, Equipment & Other Expenses include all ancillary but crucial costs like dry dock fees, equipment rental, waste disposal, and environmental compliance fees. This structured approach moves beyond simple paint price estimates to provide a defensible and realistic budget, forming the foundation of a financially successful marine coating project.

![[Image Placeholder]Title: Naval Architect Reviewing Vessel BlueprintsIntroduction: A project manager or naval architect meticulously reviewing vessel blueprints on a large screen, with cost calculation spreadsheets visible in the background, symbolizing precision and professional planning.Prompt: A clean, modern office setting. A professional project manager is pointing at a detailed digital blueprint of a large commercial vessel on a large screen. On a secondary monitor, a complex cost calculation spreadsheet is visible. The atmosphere is focused and professional, emphasizing data-driven decision-making. [Image Placeholder]Title: Naval Architect Reviewing Vessel BlueprintsIntroduction: A project manager or naval architect meticulously reviewing vessel blueprints on a large screen, with cost calculation spreadsheets visible in the background, symbolizing precision and professional planning.Prompt: A clean, modern office setting. A professional project manager is pointing at a detailed digital blueprint of a large commercial vessel on a large screen. On a secondary monitor, a complex cost calculation spreadsheet is visible. The atmosphere is focused and professional, emphasizing data-driven decision-making.](https://jdmarinepaint.com/wp-content/uploads/2025/09/naval-architect-reviewing-vessel-blueprints.webp)

By breaking down this master formula into its core components, you can transform a complex estimation into a manageable, step-by-step process. Let’s dive into each variable to build your project budget with confidence.

What Is the Core Formula to Calculate Marine Paint Project Cost?

Relying on guesswork or incomplete data to budget for a large-scale marine coating project is a high-risk strategy that often leads to significant financial strain and project delays. Key decision-makers need a reliable, repeatable method to justify expenses and ensure profitability, but often struggle to consolidate all the variables into one coherent calculation.

The universal framework to calculate marine paint project cost can be distilled into a foundational formula: Total Cost = (Total Material Cost) + (Total Labor Cost) + (Equipment & Other Expenses). This master calculation provides a structured approach to budgeting by segmenting costs into three primary categories. By meticulously calculating the expenses within each component—from paint consumption and man-hours to dry dock fees—you can build a comprehensive and accurate financial forecast. This formula serves as the backbone for any B2B marine coating project, from a small yacht repaint to a full commercial vessel recoating, ensuring no major expense is overlooked.

This formula provides the structure. Now, let’s explore the details of each component to ensure your marine project budgeting is precise.

Component 1: Calculating Total Material Cost

The foundation of your material cost is the sub-formula:

Material Cost = (Total Surface Area ÷ Spreading Rate) × Price per Gallon × Number of Coats

- Total Surface Area (m²/ft²): First, determine the precise area for all sections to be coated (underwater hull, topsides, deck, superstructure). This data is typically found in the vessel’s specifications or can be calculated using specialized naval architecture software.

- Paint Spreading Rate & Film Thickness: This is a critical variable. The Theoretical Spreading Rate (TSR) provided on a technical data sheet assumes a perfectly smooth, non-porous surface with zero waste. In reality, you must use the Practical Spreading Rate (PSR), which accounts for surface roughness, application method, and paint loss (waste factor). Your project specifications will dictate a required Dry Film Thickness (DFT), which directly impacts the spreading rate and is essential for ensuring coating performance and longevity. For more guidance on specialized coating calculations, resources like these Industrial Coating Calculators can be helpful.

- Paint Unit Price: Prices vary significantly across the coating system. High-performance primers like our JDH819 Epoxy Zinc Phosphate Primer, advanced antifouling systems like the JD753 Tin-free self-polishing antifouling paint, and durable topcoats such as the JD918 Acrylic Polyurethane Hull Paint all have different price points that must be factored in individually.

Component 2: Calculating Total Labor Cost

Labor is often one of the largest expenses. The sub-formula is:

Labor Cost = (Total Man-Hours for Prep + Total Man-Hours for Application) × Hourly Labor Rate

- Man-Hours Breakdown: Estimate the man-hours required for each stage. Surface preparation (blasting, power tooling, sanding) is typically more time-consuming than the application itself (spraying, rolling). The vessel’s current condition is the biggest factor here.

- Hourly Labor Rate: Labor rates for skilled marine painters and blasters vary by region, experience, specific certifications, and the policies of the shipyard.

Component 3: Calculating Equipment & Other Expenses

This category is a summation of all non-paint and non-labor costs. Create a checklist to avoid overlooking items:

- Scaffolding and staging rental

- Spray equipment (purchase/rental and maintenance)

- Safety gear (PPE) and consumables (tape, brushes, solvents)

- Dry dock fees and haul-out/launch charges

- Environmental compliance costs (containment, ventilation) and waste disposal fees

What Practical Tools Help Calculate Marine Paint Project Cost?

Moving from a theoretical formula to a practical, actionable budget can be daunting, especially when juggling numerous variables for a large-scale project. A simple error in calculating paint volume or overlooking a single ancillary cost can have a cascading effect, leading to significant budget deviations and putting project managers in a difficult position.

To bridge the gap between theory and application, practical tools like digital calculators and structured spreadsheets are invaluable. An online marine coating cost estimator or a custom-built Excel template provides a standardized, repeatable method to calculate marine paint project cost. These tools allow you to input key variables—such as vessel dimensions, paint system specifications (DFT, TSR), labor rates, and fixed costs—to generate a quick and organized estimate. This not only streamlines the budgeting process but also ensures consistency and accuracy across multiple projects, empowering procurement officers and shipyard estimators to make data-driven decisions.

The Marine Paint Cost Calculator: A Digital Solution

An online boat paint calculator or a custom spreadsheet is a powerful asset for quick and accurate estimates. Many manufacturers offer a basic Paint Manufacturer’s Calculator Tool for volume, but a comprehensive project tool should include:

- Key Inputs: Vessel dimensions (LOA, Beam, Draft) or direct surface area, paint system details (DFT, TSR, price/gallon for each coat), labor rates, estimated man-hours, and fixed costs like dry docking.

- Standardization: Using such a tool standardizes the cost analysis marine paint process, making quotes and budgets consistent and easier to compare.

Free Tool: A Downloadable Excel Template

To provide tangible value, a downloadable Excel sheet is the perfect takeaway. A well-structured template can guide you through the entire calculation process.

Template Structure Outline:

| Sheet Name | Purpose & Key Columns |

|---|---|

| Project Inputs | A central hub for all primary data: Vessel Name, Dimensions, key Surface Areas (Underwater Hull, Topsides, Deck), and the master Hourly Labor Rate. |

| Material Calc. | Rows for each coating layer (e.g., JDH815 Iron Oxide Red Epoxy Primer, Mid-Coat, Antifouling). Columns for Area, DFT, TSR, % Waste, PSR, Gallons Needed, Price/Gallon, Total Cost. |

| Labor & Equip. | Rows for tasks (Surface Prep, Application) and equipment (Scaffolding, Waste Disposal). Columns for Man-Hours or Units, Rate, and the resulting Total Cost. |

| Project Summary | A dynamic dashboard that pulls the grand totals from all other sheets. It provides a clear final project cost and can calculate key metrics like cost-per-square-foot/meter for high-level analysis. |

How Do You Apply This Formula in a Real-World Scenario?

The formulas and tools are powerful, but their true value is revealed when applied to a real-world project. Abstract numbers for spreading rates and labor hours can be difficult to visualize, making it hard for project managers and procurement officers to trust their own estimates without a concrete example.

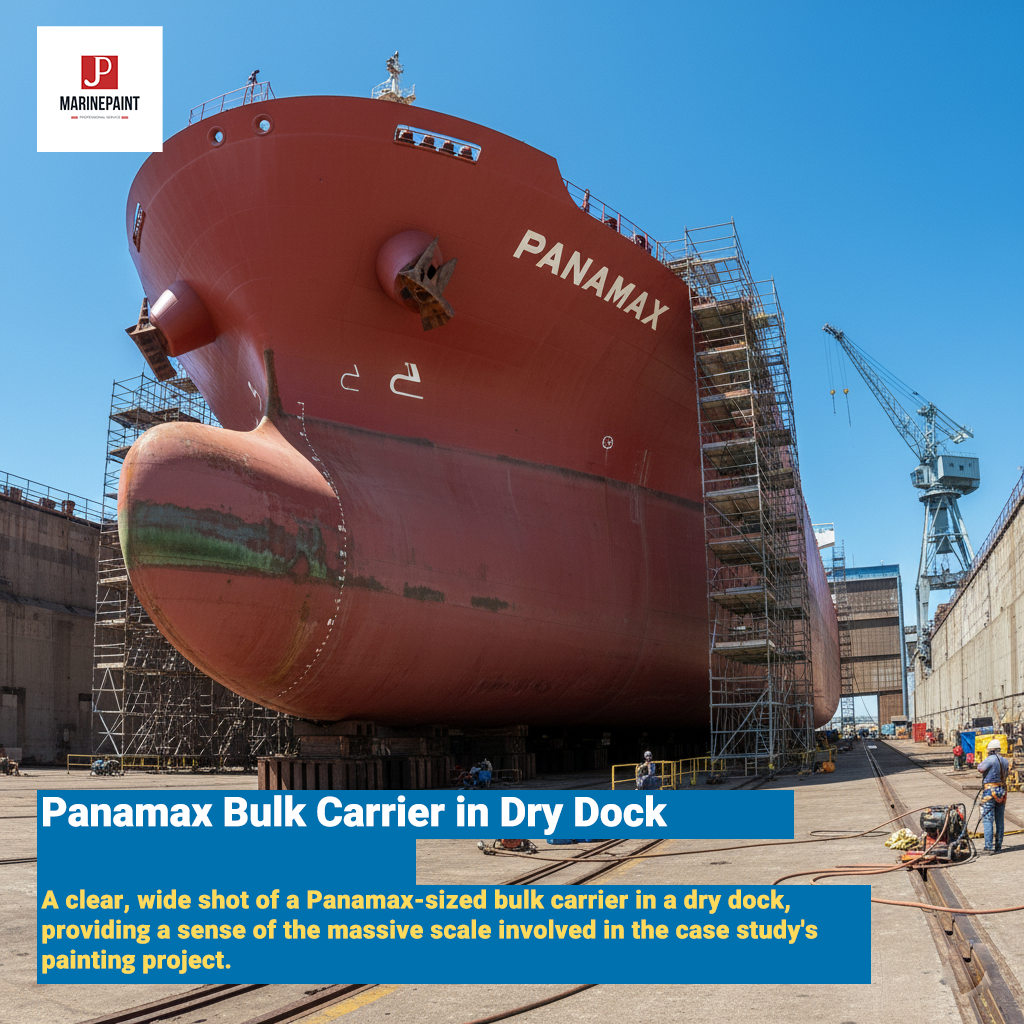

Let’s walk through a case study to calculate the marine paint project cost for a Panamax Bulk Carrier. This step-by-step example will demonstrate exactly how to apply the formulas, converting vessel specifications and project scope into a tangible, itemized budget. By breaking down the material, labor, and ancillary costs for a large-scale, common vessel type, we can clearly illustrate the process and highlight how each variable contributes to the final project cost, providing a practical blueprint for your own estimations.

This demonstration shows how the structured approach works in practice.

Step 1: Define Vessel Specifications and Project Scope

- Vessel: Panamax Bulk Carrier

- Underwater Hull Area: ~6,000 m²

- Topsides Area: ~3,500 m²

- Scope: Full abrasive blast and repaint of the underwater hull with a complete antifouling system. Full repaint of the topsides.

Step 2: Calculate Material Costs (Underwater Hull Example)

Here, we’ll focus on the underwater hull system for clarity.

- Epoxy Primer (1 Coat):

- Volume Needed: 6,000 m² ÷ 7 m²/L (PSR) = ~857 Liters

- Cost: 857 L × $30/L = $25,710

- Antifouling Paint (2 Coats):

- Volume Needed: (6,000 m² × 2 coats) ÷ 8 m²/L (PSR) = 1,500 Liters

- Cost: 1,500 L × $50/L = $75,000

- Total Underwater Material Cost: $100,710

Step 3: Calculate Labor Costs

- Surface Preparation (Blasting):

- Man-Hours: 6,000 m² @ 15 m²/hr per team = 400 Man-Hours

- Cost: 400 hours × $50/hr = $20,000

- Paint Application (Primer + 2x AF):

- Total Area to Cover: 6,000 m² (Primer) + 12,000 m² (AF) = 18,000 m²

- Man-Hours: 18,000 m² @ 50 m²/hr per team = 360 Man-Hours

- Cost: 360 hours × $50/hr = $18,000

- Total Labor Cost: $38,000

Step 4: Add Equipment, Dry Dock, and Other Expenses

- Dry Dock Fees (10 days): $100,000

- Equipment & Consumables: $15,000

- Waste Disposal & Environmental: $5,000

- Total Other Costs: $120,000

Step 5: Final Marine Paint Project Cost Calculation

Grand Total = $100,710 (Materials) + $38,000 (Labor) + $120,000 (Other) = $258,710

What Common Pitfalls Inflate Marine Paint Project Costs?

Even with a solid formula, projects can go over budget if certain common but critical details are overlooked. Many estimators focus on the big-ticket items like paint and dry dock fees, but neglect the smaller, cumulative factors that can quietly inflate the final invoice, leading to unexpected financial pressure and difficult conversations with stakeholders.

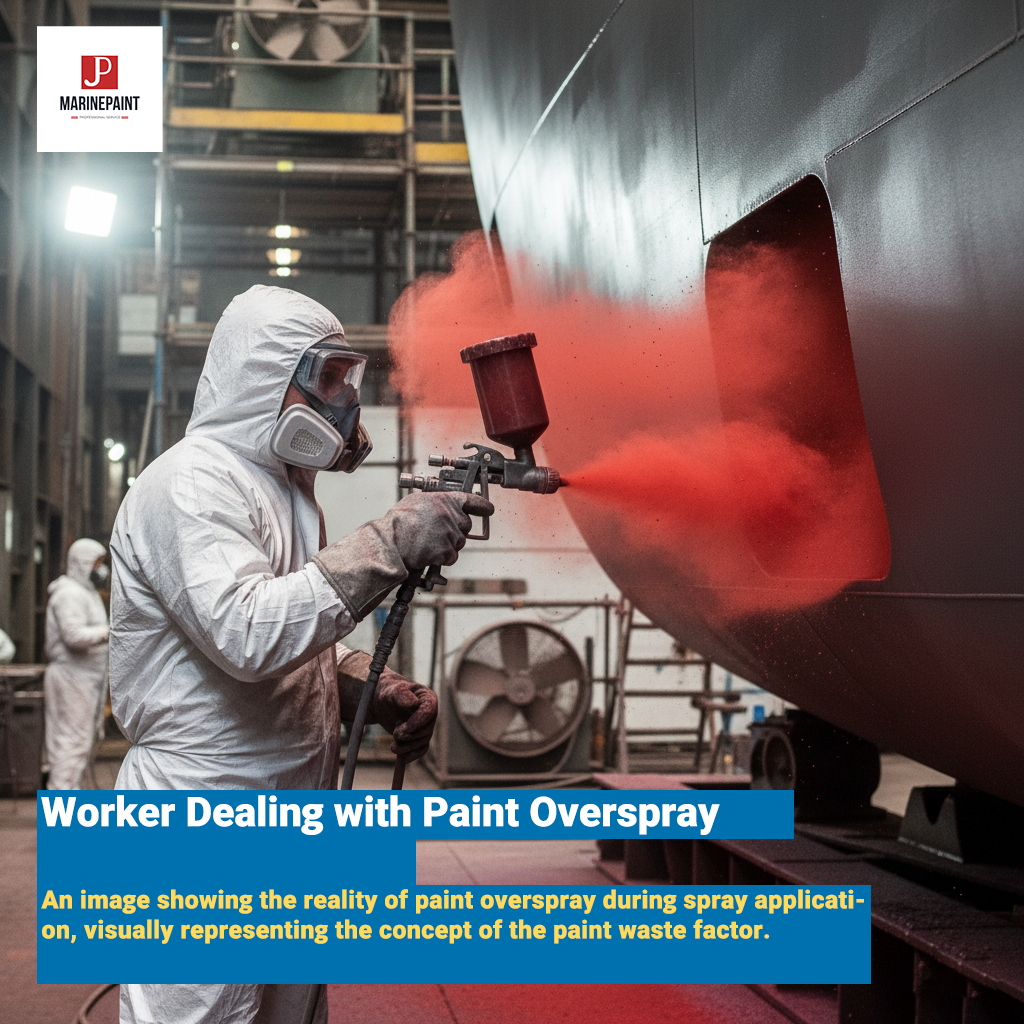

To ensure your budget remains robust, you must be aware of the common pitfalls that inflate your marine paint project cost. These include underestimating the paint waste factor from overspray, which can be as high as 30%; misjudging the man-hours needed for complex surface preparation on heavily corroded hulls; forgetting to budget for ancillary materials like solvents and masking tape; and failing to account for the immense business cost of vessel downtime. Recognizing and planning for these hidden costs is essential for accurate forecasting and successful cost control. Adherence to best practices, such as those outlined in the IMO biofouling management guidelines, can also help mitigate unforeseen preparation complexities.

Conclusion: Take Control of Your Budget by Mastering the Cost Calculation

A reliable marine paint project cost calculation is built on a solid formula, practical tools, and an awareness of common pitfalls. Mastering this structured approach is key to financial success.

By adopting this disciplined B2B methodology, your business can budget more effectively, negotiate with confidence, and achieve better financial outcomes on every single marine coating project you undertake.

![]()