Rust and fouling slowing your vessel down? A full hull refurbishment seems complex and costly. Discover how a systematic coating process brings a ship back to life.

Refurbishing a deck cargo ship’s hull involves a multi-stage process starting with thorough surface preparation, typically abrasive blasting to a Sa2.5 standard to remove old coatings and corrosion. This is followed by applying specialized coating systems tailored to different areas of the hull. For underwater sections, this includes epoxy anti-corrosive primers and antifouling paints. The area above water, including the boot-top and topside, receives a different system designed for UV resistance, color retention, and atmospheric protection, often finished with a durable acrylic or polyurethane topcoat. Each layer plays a crucial role in protecting the steel, ensuring the vessel’s longevity and operational efficiency.

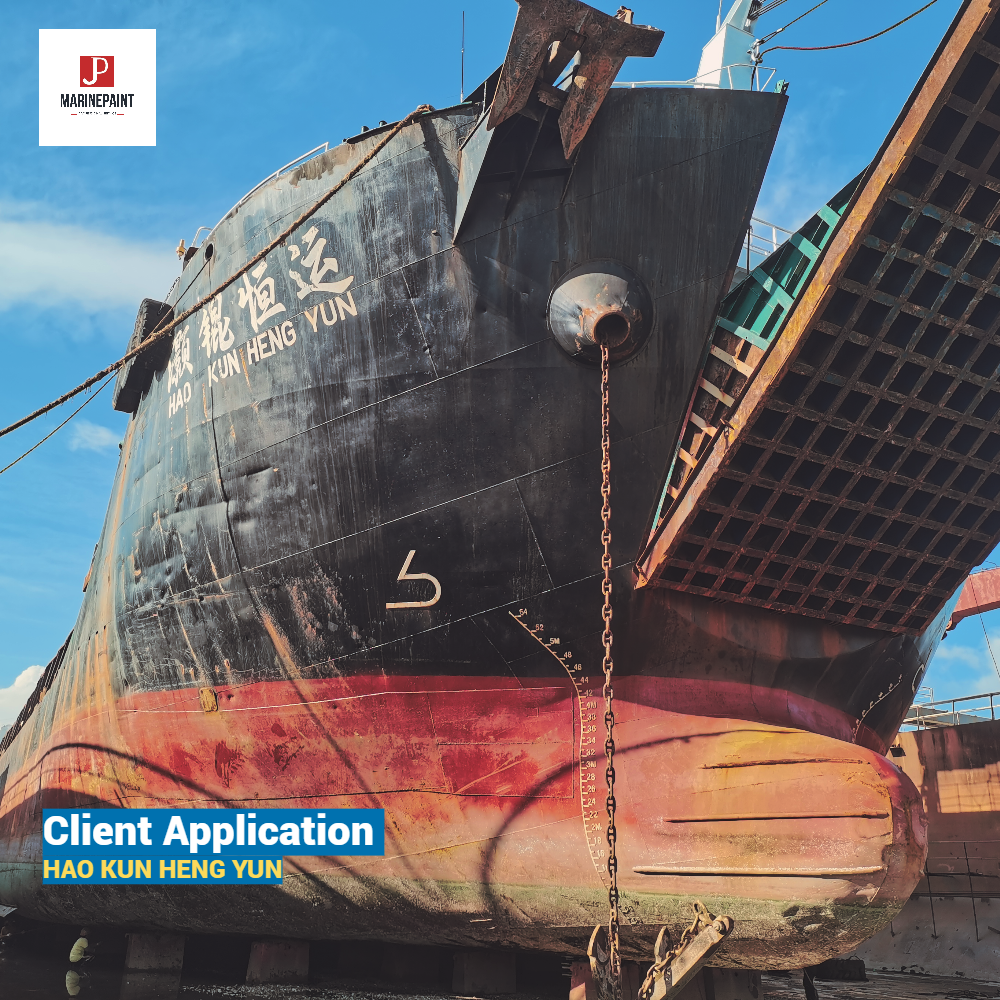

This meticulous process might seem daunting, but breaking it down reveals a clear, logical path to full restoration. As a technical consultant at JDmarine Paint, I’d like to walk you through a recent project on the deck cargo ship "Hao Kun Heng Yun" to demonstrate how our high-performance coatings are applied in the real world.

The "Hao Kun Heng Yun" is a workhorse of the seas, with a length of 92 meters, a beam of 20.8 meters, and a moulded depth of 6 meters. After years of service, she was due for a full-system refurbishment to restore her protective coatings and optimize performance.

What’s the First Step for Long-Lasting Hull Protection?

Simply painting over old, corroded surfaces is a recipe for disaster. Flaking paint, hidden rust, and salt contamination will quickly undermine the new coating, leading to premature failure and costly re-work. You need a clean, perfectly prepared foundation for the new paint system to bond effectively and provide long-lasting protection. Without this crucial first step, even the most advanced marine coatings will fail.

The most critical first step is comprehensive surface preparation. Before any paint can be applied, the substrate must be pristine. The process begins with high-pressure freshwater washing to remove salt, marine life, and loose contaminants. Following this, any damaged or heavily corroded areas are scraped and ground down. For the "Hao Kun Heng Yun," we specified a full abrasive blast cleaning to standard Sa2.5 [7, 15]. This removes all old paint, rust, and mill scale, creating an ideal surface profile for the new primer to anchor into, ensuring maximum adhesion and the long-term integrity of the entire coating system.

![[Image placeholder]*Prompt: A close-up, detailed shot of a worker in full protective gear using an industrial sandblasting hose on the steel hull of a ship. Sparks and dust are visible as rust and old paint are stripped away, revealing the rough, clean metal underneath.* [Image placeholder]*Prompt: A close-up, detailed shot of a worker in full protective gear using an industrial sandblasting hose on the steel hull of a ship. Sparks and dust are visible as rust and old paint are stripped away, revealing the rough, clean metal underneath.*](https://jdmarinepaint.com/wp-content/uploads/2025/08/8月21日.gif)

Proper surface preparation isn’t just a recommendation; it’s the bedrock of marine protection. An improperly prepared surface is the primary cause of coating failures.

Why Sa2.5 is the Gold Standard

The quality of the blast determines the lifespan of the coating. We adhere to the Swedish Standard SIS 05 59 00 for surface preparation, with Sa2.5 being the industry benchmark for high-performance systems.

| Standard | Description | Suitability |

|---|---|---|

| St3 | Very thorough power tool cleaning | Suitable for minor repairs or less critical areas [7]. |

| Sa2 | Thorough blast cleaning | Most rust and scale removed. A common standard for general maintenance. |

| Sa2.5 | Very thorough blast cleaning | Surface is free from visible contaminants. The standard for new coatings and full refurbishments [15]. |

| Sa3 | Blast cleaning to pure metal | Removes 100% of contaminants. Typically reserved for the most demanding applications. |

For a full refurbishment aiming for years of service life, anything less than Sa2.5 compromises the investment in high-quality paints. Once blasting is complete, the surface is cleaned of all dust and debris, ready for the immediate application of the first primer coat to prevent flash rusting.

How Do You Paint the Underwater Hull for Peak Performance?

The ship’s underwater hull faces constant attack from corrosive seawater and marine organisms like barnacles and algae. This biofouling increases drag, which significantly raises fuel consumption and operational costs. A simple paint job won’t suffice; you need a multi-layered, synergistic system designed to provide a robust anti-corrosive barrier and an effective antifouling surface. Choosing the right combination of products is critical to protecting the asset and ensuring its efficiency through the water.

To protect the underwater hull of the "Hao Kun Heng Yun," a high-performance, multi-coat system is essential. After blasting, the first layer is an epoxy anti-corrosive primer. We applied two coats of our JDH815 Iron Red Epoxy Primer with a total Dry Film Thickness (DFT) of 150 microns to create a hard, impermeable barrier. Next, we applied one coat of JDH263 Epoxy Tie Coat [11, 28]. This layer is crucial for ensuring a strong chemical bond between the epoxy primer and the subsequent antifouling paint. Finally, we applied three coats of our JD753 Self-Polishing Antifouling paint to a DFT of 300 microns. This advanced coating slowly releases biocides to prevent marine growth and polishes smoothly as the ship moves, maintaining a clean hull.

Each layer in this system has a distinct and vital role. Skipping a step or using an incompatible product can lead to delamination, corrosion, and ultimately, system failure.

Breakdown of the Underwater Coating System

Here’s a closer look at the function and specifications for each layer applied to the underwater hull of the "Hao Kun Heng Yun."

| Layer | Product Used | Coats | DFT per Coat | Total DFT | Purpose |

|---|---|---|---|---|---|

| Primer | JDH815 Iron Red Epoxy Primer | 2 | 100µm | 200µm | Creates a tough, anti-corrosive barrier to protect steel from seawater [15]. |

| Tie Coat | JDH263 Epoxy Tie Coat | 1 | 100µm | 100µm | Ensures excellent adhesion between the epoxy primer and the antifouling topcoat [28]. |

| Antifouling | JD753 Self-Polishing Paint | 1 | 100µm | 100µm | Prevents marine biofouling, reducing drag and improving fuel economy. |

| Total DFT | 4 | 400µm | Complete Underwater Protection |

This systematic approach, combining robust physical protection with advanced chemical technology, is the key to a long-lasting, high-performance underwater hull.

How Do You Protect the Hull Above the Water?

The area above the water seems less demanding, but it’s constantly battered by UV radiation, salt spray, and mechanical impacts from operations. A faded, chalky, or rust-streaked topside ruins a ship’s appearance and signals underlying corrosion. You need a coating system that provides both aesthetic appeal and robust, long-lasting protection against the harsh atmospheric marine environment.

Protecting the topside (freeboard) and waterline (boot-top) involves applying a multi-coat system over the same foundational anti-corrosive primer used below the water. The key difference is the topcoat. These areas require finishes with excellent weather resistance, gloss retention, and durability. For the "Hao Kun Heng Yun," we applied our advanced acrylic and polyurethane systems. These paints are specifically formulated to withstand UV degradation while providing a smooth, high-quality finish that is easy to clean and maintains the vessel’s appearance for years. [2]

Different zones above the water face unique challenges, requiring slightly different approaches to ensure maximum protection.

The Critical Boot-Top Area (Waterline)

The boot-top is the area that alternates between being submerged and exposed to air as the vessel is loaded and unloaded. This zone is subject to abrasion, constant wet/dry cycles, and marine growth, making it one of the toughest areas to protect.

After applying the initial epoxy primers, this area was coated with two layers of our JDB902 Acrylic Hull Paint [2, 30]. This topcoat provides a tough, flexible film with excellent adhesion and resistance to water and weathering. Its finish is specifically designed to withstand the unique stresses of the waterline, preventing premature breakdown and corrosion.

The Topside: A Balance of Protection and Aesthetics

The topside, or freeboard, is the most visible part of the ship’s hull. Its coating must provide superior protection against UV radiation, which causes colors to fade and paint to chalk, while also resisting atmospheric corrosion from salt spray.

For the "Hao Kun Heng Yun," the topside was also coated with our JDB902 Acrylic Hull Paint over the epoxy primer system [2]. This high-gloss finish is not just for looks; it provides a durable, non-porous surface that repels water and contaminants. Its excellent color and gloss retention ensure the vessel maintains a professional appearance between maintenance cycles, directly reflecting the quality of its upkeep. For an even higher level of durability and chemical resistance, an acrylic polyurethane topcoat like our JD908 could also be specified [9].

| Area | Product System | Total DFT | Key Benefits |

|---|---|---|---|

| Boot-Top | 2x JDH815 Epoxy Primer + 2x JDB902 Acrylic Paint | 300µm | Resists abrasion, weathering, and constant wet/dry cycles. |

| Topside | 2x JDH815 Epoxy Primer + 2x JDB902 Acrylic Paint | 300µm | Excellent UV resistance, color/gloss retention, and aesthetic appeal [2]. |

Conclusion

Refurbishing a vessel like the "Hao Kun Heng Yun" is a testament to how a systematic approach and high-performance coatings transform and protect a vital maritime asset for years to come.

![]()