Your marine deck is constantly under assault from foot traffic, heavy equipment, and harsh weather. This relentless wear can lead to rapid surface degradation, creating safety hazards and costly repairs.

Choosing the best wear-resistant deck paint involves selecting a complete marine coating system designed for high-traffic areas. The ideal choice forms a tough, durable film that demonstrates excellent adhesion to both metal and wood substrates. It must offer superior resistance to mechanical abrasion, impact, and harsh marine environments, including constant exposure to water and UV radiation. A top-tier system, often comprising an anti-rust primer and a specialized topcoat like a robust alkyd deck paint, not only prevents corrosion but also maintains its color and gloss over time. This ensures the longevity and safety of ship decks, docks, and other maritime steel structures, making it a critical investment in asset protection.

![[Image Placeholder]> Prompt: A dynamic, wide shot of a freshly painted, vibrant green ship deck. The paint has a slight gloss, reflecting the bright sun. In the background, the open sea and a clear blue sky. The focus is on the texture and resilience of the paint surface. [Image Placeholder]> Prompt: A dynamic, wide shot of a freshly painted, vibrant green ship deck. The paint has a slight gloss, reflecting the bright sun. In the background, the open sea and a clear blue sky. The focus is on the texture and resilience of the paint surface.](https://jdmarinepaint.com/wp-content/uploads/2025/08/a-dynamic-wide-shot-of-a-freshly-painted-vibrant-2.png)

Understanding the essentials of a high-performance deck coating is the first step. Now, let’s explore the specific qualities that define a truly durable wear-resistant deck paint and how to choose the right type for your needs.

What Key Characteristics Define a Truly Wear-Resistant Deck Paint?

Selecting a deck paint based on price or color alone can be a costly mistake. Marine and dock surfaces face extreme conditions that standard paints simply cannot withstand, leading to premature failure, constant maintenance, and compromised safety from peeling or flaking surfaces. Investing in a subpar product results in a cycle of stripping and repainting, wasting both time and resources while leaving your valuable assets vulnerable to corrosion and decay.

A truly effective wear-resistant deck paint is defined by a combination of critical properties that work together to provide lasting protection. The primary characteristic is its ability to form a tough and durable paint film that can withstand significant abrasion and impact from foot traffic, cargo, and equipment. Excellent adhesion is non-negotiable; the coating must bond tenaciously to metal or wood surfaces to prevent peeling. Furthermore, superior weather and water resistance is essential for any marine coating, as it must endure constant exposure to moisture, UV rays, and salt spray. Finally, good color and gloss retention ensures the surface remains not only protected but also aesthetically pleasing and highly visible for safety.

These characteristics are the foundation of a reliable coating. Let’s break down how these features manifest in different types of paint systems, particularly those proven in marine applications.

Core Properties of a High-Performance Marine Deck Coating

To make an informed decision, it’s crucial to understand the technical attributes that contribute to the paint’s overall performance. These are the qualities we, as technical consultants, prioritize when recommending a system.

| Characteristic | Why It Matters | Impact on Performance |

|---|---|---|

| Tough & Durable Film | The coating’s first line of defense against mechanical stress. | Resists scratches, scuffs, and impact from daily operations, preventing cracks that allow moisture ingress. |

| Excellent Adhesion | Ensures the paint stays bonded to the substrate under stress and flexing. | Prevents common failures like peeling, flaking, and blistering, which expose the underlying surface to rust. |

| Weather & Water Resistance | Protects the substrate from the corrosive effects of the marine environment. | Shields against rust on steel and rot on wood by creating an impermeable barrier against saltwater and rain. |

| Color & Gloss Retention | Maintains the deck’s appearance and visibility for safety markings. | Resists fading and chalking from UV exposure, ensuring long-term aesthetic appeal and functional visibility. |

Which Type of Wear-Resistant Deck Paint Offers the Best Balance of Performance and Usability?

While advanced systems like epoxy paint and polyurethane topcoats offer maximum protection, they often require complex application procedures and specific environmental conditions. For many ship operators and dock managers, finding a durable deck coating that is also practical and easy to apply is a top priority. The challenge lies in sourcing a product that delivers robust, anti-wear protection without demanding specialized equipment or extensive downtime, ensuring maintenance remains efficient and cost-effective.

For a superb balance of performance, durability, and ease of application, alkyd-based solutions are a leading choice for wear-resistant deck paint. These single-component paints are renowned for their user-friendly nature and reliable protective qualities. A prime example from our portfolio is the JDC42-32 Alkyd Deck Paint. Formulated with high-quality alkyd resin, durable pigments, and effective driers, it creates a tough, bright, and full film. Its exceptional adhesion and inherent weather resistance make it an ideal anti-wear coating for both metal surfaces and wood surface paint applications on ship decks and marine facilities.

The practicality of alkyd systems extends beyond their initial application. They offer excellent flow and leveling, which simplifies achieving a uniform finish, whether by high-pressure airless spray, rolling, or brushing.

Why Alkyd Paint Excels in Marine Environments

Alkyd resins provide a unique combination of flexibility and hardness. This allows the paint film to withstand the minor flexing of a ship’s structure while being tough enough to resist abrasion.

-

Composition and Benefits: The JDC42-32 Alkyd Deck Paint is a testament to this technology. Its formulation is specifically engineered for marine use:

- Alkyd Resin Base: Provides excellent adhesion and flexibility.

- Durable Pigments: Ensure long-lasting color and UV resistance.

- Fast-Acting Driers: Allow for quicker drying times, minimizing downtime.

-

Versatility in Application: Designed as a topcoat, it is suitable for:

- Ship Decks: Protecting steel from corrosion and wear.

- Docks and Piers: Shielding both metal and wood structures from the elements.

- Superstructures: Providing a durable, aesthetic finish above the waterline.

This versatility, combined with straightforward application, makes it a go-to choice for reliable protection.

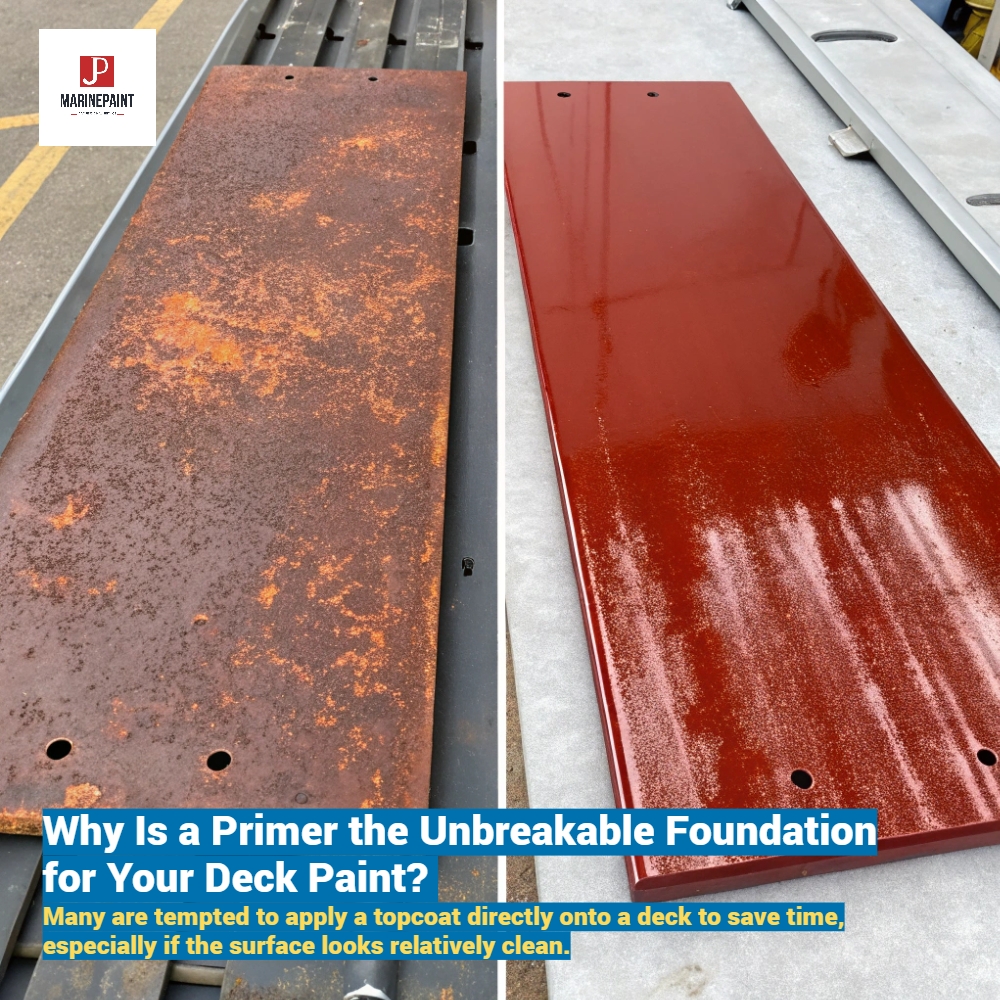

Why Is a Primer the Unbreakable Foundation for Your Deck Paint?

Many are tempted to apply a topcoat directly onto a deck to save time, especially if the surface looks relatively clean. However, this is a critical error. Applying even the best wear-resistant deck paint without a proper foundation invites premature failure. The topcoat alone cannot provide sufficient anti-corrosion protection or create the strong, stable bond needed to withstand the harsh marine environment. This oversight leads to blistering, peeling, and rapid rust formation, ultimately requiring a complete and costly rework of the entire surface.

A high-quality anti-rust primer is the non-negotiable foundation of a durable marine coating system. Its primary role is to provide anti-corrosion protection and create a perfectly prepared surface for the topcoat to adhere to. For an alkyd deck paint, a compatible alkyd-based anti-rust primer like JDC53-36 Iron Red Alkyd Anti-Rust Paint or a zinc grey variant is an excellent choice, ensuring system compatibility. For environments demanding even higher performance and superior salt mist resistance, applying a high-performance epoxy anti-rust primer first will establish an incredibly tough and resilient base, significantly extending the life and durability of the entire paint system.

The synergy between the primer and topcoat is what creates a truly long-lasting barrier. Investing in the right primer is just as important as choosing the topcoat itself.

Selecting the Right Primer for Your Alkyd Topcoat

The choice of primer depends on the substrate, environmental conditions, and desired performance level. A well-chosen primer ensures optimal adhesion and provides the primary layer of anti-corrosion defense.

-

Standard Protection: Alkyd Primers

- Recommended Use: For general marine applications on steel structures where good performance and cost-effectiveness are key.

- Product Example: Iron red or zinc grey alkyd primers are industry standards. They create a strong bond with both the steel substrate and the subsequent alkyd topcoat.

- Benefits: Easy to apply, relatively fast-drying, and specifically designed to work seamlessly with alkyd topcoats.

-

High-Performance Protection: Epoxy Primers

- Recommended Use: For areas with high humidity, frequent water contact, or exposure to chemicals and salt spray. Ideal for new builds or major refurbishments where longevity is paramount.

- Product Example: A robust epoxy primer like JDH835 Aluminum Iron Epoxy Anti-Rust Paint offers exceptional durability.

- Benefits: Creates a harder, more impermeable barrier with superior resistance to corrosion, chemicals, and abrasion. While it requires more precise application, the long-term protection is unparalleled. For an even more premium finish, it can be top-coated with an acrylic polyurethane topcoat for outstanding gloss and color retention.

Conclusion

Choosing the right wear-resistant deck paint is a crucial investment in the safety, longevity, and value of your marine assets. Success depends on a complete system approach.

![]()