Epoxy vs. Alkyd Marine Paint: Which Offers the Best Value?

Choosing marine paint based on price alone is a risky voyage. This short-sighted decision often leads to premature coating failure, spiraling maintenance costs, and crippling operational downtime for your valuable maritime assets.

In the marine paint price comparison of epoxy vs. alkyd, the answer depends on your timeframe. While alkyd paint offers a significantly lower upfront cost per gallon (around $30-$60), making it attractive for tight initial budgets, its shorter service life of 2-4 years leads to frequent, expensive repaint cycles. Conversely, epoxy coatings, despite a higher initial price tag ($80-$150+), deliver a vastly superior service life of 7-12 years. This exceptional durability dramatically reduces the need for costly labor, dry docking, and downtime, making epoxy the more cost-effective and strategic investment for the long-term protection and operational readiness of any critical marine asset.

![[Image Placeholder]Title: Upfront Cost vs. Long-Term ValueIntroduction: This visual starkly contrasts the outcome of choosing a paint based on initial price versus long-term performance, highlighting how an initial saving can lead to premature failure.Prompt: A split-screen, high-contrast image. The left side is labeled [Image Placeholder]Title: Upfront Cost vs. Long-Term ValueIntroduction: This visual starkly contrasts the outcome of choosing a paint based on initial price versus long-term performance, highlighting how an initial saving can lead to premature failure.Prompt: A split-screen, high-contrast image. The left side is labeled](https://jdmarinepaint.com/wp-content/uploads/2025/10/upfront-cost-vs.-long-term-value.webp)

To truly appreciate this value proposition, we must dissect both the immediate investment and the long-term financial implications. This comparison will empower you to make a data-driven decision that aligns with your operational and financial goals.

Is Alkyd Always Cheaper Than Epoxy at First Glance?

For procurement managers and vessel owners facing strict initial budget constraints, the high price-per-gallon of an epoxy system can be an immediate deterrent. This focus on the upfront cost can steer decisions towards seemingly more economical options, creating the risk that the vessel’s long-term protection is compromised for a short-term saving. Without understanding the context behind the price difference, it’s easy to make a choice that proves more expensive down the line.

Yes, a direct marine paint price comparison of epoxy vs. alkyd shows that alkyd is significantly cheaper on an initial, per-gallon basis. Alkyd marine paints typically range from $30 to $60 per gallon, whereas high-performance epoxy systems can cost between $80 and $150+ per gallon. This substantial price difference is not arbitrary; it is rooted in the fundamental chemistry and manufacturing of the products. Epoxy’s two-component system, which creates a highly cross-linked and durable film, relies on more expensive raw materials and a more complex manufacturing process than traditional, single-component, oil-based alkyds. This makes alkyd the clear winner for minimal upfront material expenditure, but this is only the first variable in a much larger cost equation.

Let’s break down this initial investment further to understand the complete picture.

Why the Drastic Price Difference?

The cost disparity between epoxy and alkyd coatings is driven by three core factors:

- Raw Material Costs: The foundational resins are fundamentally different. Alkyd resins are relatively simple and inexpensive to produce. Epoxy resins are a product of more advanced polymer chemistry, making them inherently more costly.

- Manufacturing Complexity: Alkyds are single-component paints that are straightforward to manufacture. Epoxies are two-component systems requiring precise formulation of both a base resin and a separate curing agent (hardener), demanding stricter quality control and a more intricate production process.

- Performance Additives: Epoxy formulations often include specialized additives to enhance properties like corrosion inhibition, abrasion resistance, and adhesion, all of which contribute to a higher price point but deliver superior performance.

A Practical Cost Scenario (Materials Only)

To illustrate the difference in upfront material costs, let’s consider a common scenario: purchasing paint for a 500 sq ft (approx. 46 m²) topside area.

| Coating System | Spreading Rate (Est.) | Gallons Needed | Price/Gallon (Est.) | Initial Material Cost |

|---|---|---|---|---|

| Alkyd Marine Paint | 300 sq ft/gallon | ~1.7 gallons | $50 | ~$85 |

| Epoxy Marine Coating | 250 sq ft/gallon | 2.0 gallons | $110 | ~$220 |

For this scenario, selecting a quality alkyd anti-rust paint like our JDC53-36 Iron Red Alkyd Anti-Rust Paint keeps initial costs low. However, upgrading to a robust primer such as our JDH815 Iron Oxide Red Epoxy Primer requires a higher upfront investment. While the alkyd system is over 60% cheaper in initial material cost, this is merely the tip of the iceberg when considering the true cost of ownership.

How Does Long-Term Durability Affect the True Cost?

Focusing solely on the initial savings of alkyd paint creates a major blind spot: the immense pain of frequent repainting. This recurring cycle is not just an inconvenience; it’s a massive drain on resources. The associated costs of dry docking, extensive labor for surface preparation, and, most critically, the lost revenue from asset downtime, can agitate any budget and disrupt operations, quickly eroding any perceived initial savings.

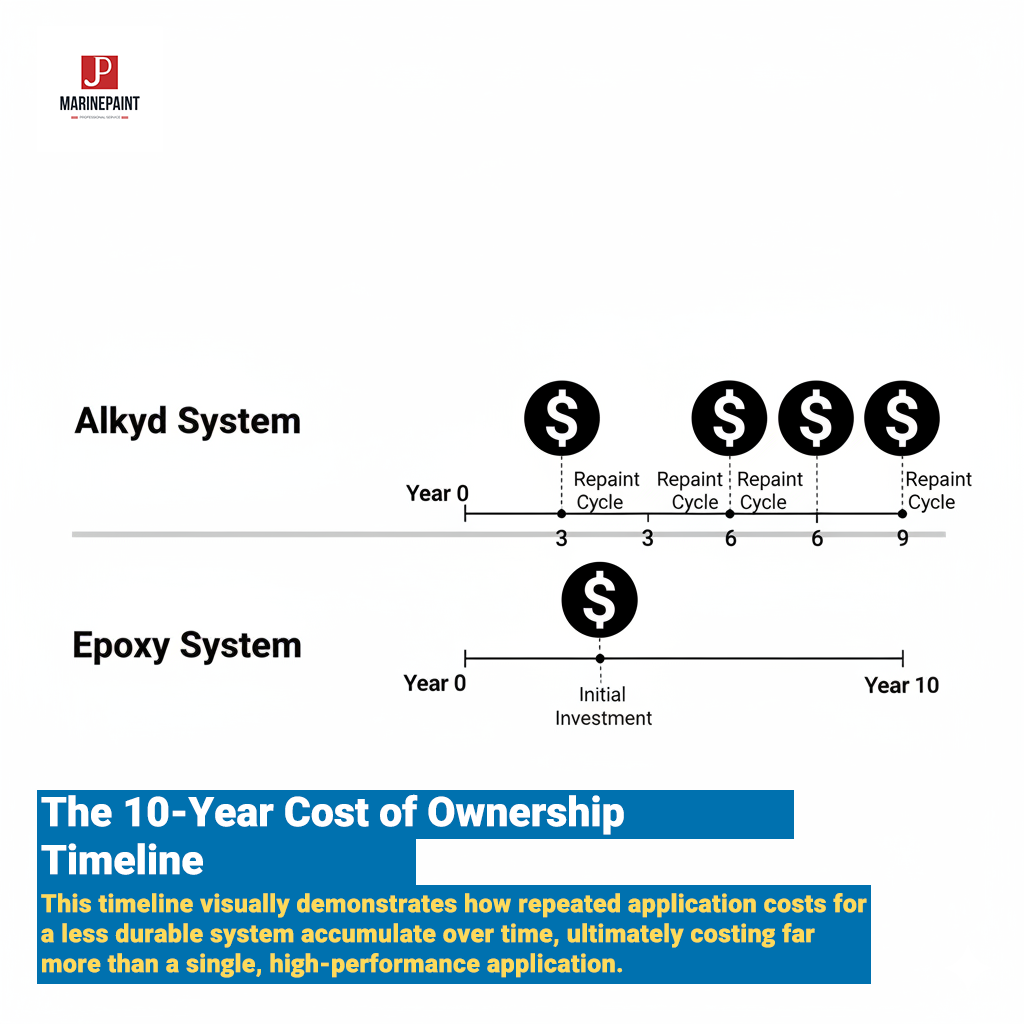

The true financial narrative is revealed through a life cycle cost analysis. The superior durability of epoxy coatings is the single most important factor in the marine paint price comparison of epoxy vs. alkyd over the long term. Epoxy systems are engineered for an expected service life of 7-12 years, offering exceptional resistance to abrasion, chemicals, and water immersion. In contrast, traditional alkyd paints offer a much shorter service life of only 2-4 years before they begin to fail, especially in harsh marine environments. This durability gap means an alkyd-coated asset will require 3 to 4 complete repaint cycles in the time an epoxy system requires only one. When you factor in the enormous costs of labor and downtime for each of those cycles, the initially more expensive epoxy becomes the overwhelmingly cost-effective choice.

Let’s quantify this difference to see how the numbers play out over a decade.

Durability, Service Life, and Re-application Costs

The core of the life cycle analysis lies in understanding that each repaint project is a major financial event. The cost of new paint is often a fraction of the total expense.

Associated Costs Per Repaint Cycle:

- Dry Docking Fees: A colossal expense, often running upwards of $10,000 per day for commercial vessels.

- Labor Costs: This includes extensive surface preparation (blasting, sanding) and skilled application, which can run into tens of thousands of dollars. Proper surface preparation standards are critical and are outlined by organizations such as SSPC (The Society for Protective Coatings).

- Asset Downtime: For any commercial vessel, this is often the biggest cost of all. Every day the asset is out of service represents thousands, or even hundreds of thousands, in lost revenue.

10-Year Life Cycle Cost Scenario (500 sq ft Area)

Using our previous scenario, let’s project the costs over a 10-year period, excluding the massive cost of dry docking for simplicity.

- Alkyd System (Repainted every 3 years):

- Year 0: $85 (paint) + $500 (labor) = $585

- Year 3: Repaint Cycle = $585

- Year 6: Repaint Cycle = $585

- Year 9: Repaint Cycle = $585

- 10-Year Total (Labor & Materials): ~$2,340

- Epoxy System (One application):

- Year 0: $220 (paint) + $600 (more rigorous prep labor) = $820

- 10-Year Total (Labor & Materials): ~$820

The conclusion is undeniable. The epoxy system, despite being more expensive upfront, is nearly 70% cheaper over a decade when only factoring in labor and materials. When you add the cost of downtime and dry-docking to the three additional alkyd repaint cycles, the savings from choosing epoxy amount to tens or even hundreds of thousands of dollars.

Which Paint Is Right for a Specific Marine Application?

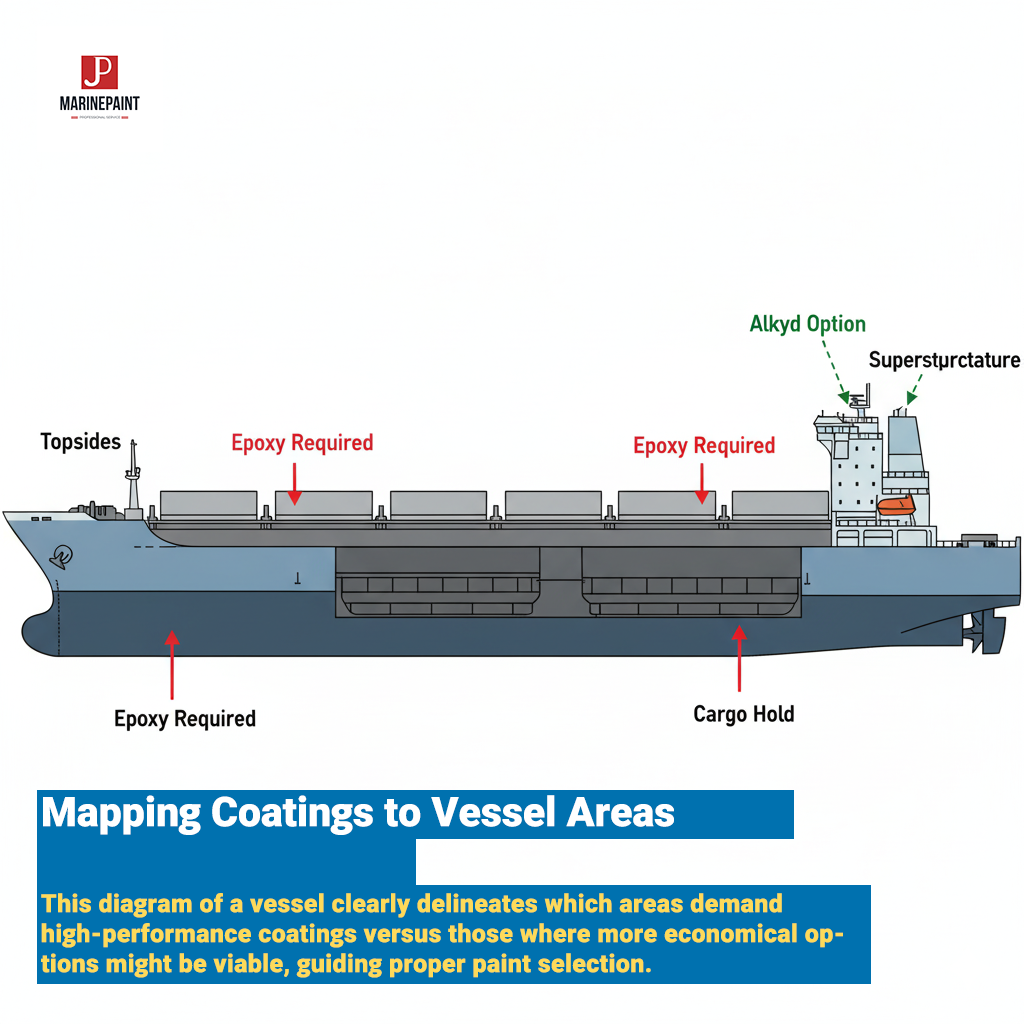

Choosing a paint system without considering its specific location and function on the vessel is a critical error. A B2B decision-maker might be tempted to apply a low-cost alkyd system universally to save money, only to face rapid coating failure in high-demand areas like the underwater hull or cargo holds, leading to catastrophic maintenance costs and safety risks. This one-size-fits-all approach ignores the technical realities of a marine environment.

The "right" paint is always the one that is technically suited for the job, and this is where the marine paint price comparison between epoxy and alkyd shifts from a financial discussion to one of technical necessity. For critical areas exposed to constant water immersion, harsh chemicals, or heavy abrasion, the superior performance of epoxy is not just a preference—it’s a requirement for asset integrity and safety. Alkyd paints, while economical, are best reserved for less demanding, above-the-waterline applications where budgets are the primary constraint. Matching the coating technology to the application ensures performance, longevity, and ultimately, the best financial outcome. Industry news and technical articles from sources like PaintSquare often highlight the importance of correct coating selection.

Let’s break down the vessel by area to make the choice clear.

Below the Waterline (Underwater Hull)

- Winner: Epoxy

- There is no contest here. Epoxy’s outstanding water immersion resistance and barrier properties are essential for protecting the hull from corrosion. It is the industry standard for barrier coats applied beneath antifouling paint. High-performance epoxy primers, such as our JDH06-4 Epoxy Zinc-Rich Anti-Rust Primer, are designed specifically for this purpose. Alkyd paints would blister and fail in a matter of months in this environment. The price comparison is irrelevant; it is a matter of technical suitability.

Above the Waterline (Topsides & Superstructure)

- Epoxy (as a primer/build coat): This is the premium choice for maximum long-term durability and corrosion protection. An epoxy primer creates a strong foundation for a high-gloss, UV-resistant polyurethane topcoat. While the initial cost is higher, the service life is far superior. For maximum protection, a system using our JDH835 Aluminum Iron Epoxy Anti-Rust Paint is an excellent investment.

- Alkyd (as a topcoat): This is a viable, low-cost option for less critical topside areas, especially on vessels with tight budgets or in situations where frequent repainting is already part of the maintenance schedule. Our range of alkyd hull paints, like the JDC43-31 Alkyd Hull Paint, offers an economical solution for these applications.

Decks and High-Traffic Areas

- Winner: Epoxy

- Marine decks endure constant abrasion from foot traffic, cargo handling, and equipment. Epoxy’s superior hardness and abrasion resistance make it the only suitable choice. An alkyd deck paint, such as our economical JDC42-32 Alkyd Deck Paint, is suitable for very light traffic areas, but for any working deck, an epoxy system is essential to avoid rapid wear and constant touch-ups.

Cargo Holds and Tanks

- Winner: Epoxy

- This is not a comparison; it is a requirement dictated by safety and regulations. Cargo holds and tanks require coatings with specific chemical resistance properties, certified for contact with everything from crude oil to potable water. Specialized epoxy tank coatings, like our JDH912 Epoxy Potable Water Tank Coating, are formulated and tested for these exact conditions. Alkyd paints are entirely unsuitable and would fail dangerously upon contact with most cargoes. Following coating standards from organizations like AMPP (formerly NACE) is critical here.

Conclusion: A Final Verdict on the Epoxy vs. Alkyd Price Comparison

The marine paint price comparison between epoxy and alkyd presents a classic investment choice. Alkyd offers a low barrier to entry for non-critical areas, while epoxy delivers dramatic long-term savings for demanding applications.

For any critical part of a marine asset, epoxy’s superior durability translates to a significantly lower life cycle cost. It is the more strategic and financially sound investment for long-term asset protection and operational readiness.

![]()