Comprehensive Marine Paint Cost Breakdown: Deconstructing Your Investment

Understanding the true marine paint cost breakdown is vital for any vessel owner or business decision-maker. It’s far more than just the price of a can of paint. Many underestimate the overall investment in a marine painting project, leading to budget overruns and unexpected expenses, which can be a significant pain point for any maritime operation.

This article provides a comprehensive marine paint cost breakdown, meticulously detailing every component from materials to potential hidden fees. By laying out the diverse factors influencing your marine paint budget, from expert labor to essential equipment and facility costs, we aim to empower you with the knowledge for smarter financial planning and successful project execution. Our insights will help you navigate the complexities, ensuring your vessel not only looks pristine but also receives the long-term protection it deserves without any budget surprises.

![[Image Placeholder]Title: Vessels Undergoing Paint MaintenanceIntroduction: A fleet of diverse maritime vessels—from sleek yachts to robust commercial ships—are shown in various stages of dry dock, some being prepped, others mid-paint application, and some freshly painted, highlighting the breadth of marine painting projects and the substantial investment they represent.Prompt: A wide shot showing various types of maritime vessels (yachts, commercial ships) in a bustling dry dock. Some boats are in preparation stages with scaffolding, others are being painted, and some appear freshly finished. Emphasize the scale and diversity of marine painting projects, with skilled workers visible. Soft, natural lighting. [Image Placeholder]Title: Vessels Undergoing Paint MaintenanceIntroduction: A fleet of diverse maritime vessels—from sleek yachts to robust commercial ships—are shown in various stages of dry dock, some being prepped, others mid-paint application, and some freshly painted, highlighting the breadth of marine painting projects and the substantial investment they represent.Prompt: A wide shot showing various types of maritime vessels (yachts, commercial ships) in a bustling dry dock. Some boats are in preparation stages with scaffolding, others are being painted, and some appear freshly finished. Emphasize the scale and diversity of marine painting projects, with skilled workers visible. Soft, natural lighting.](https://jdmarinepaint.com/wp-content/uploads/2025/09/vessels-undergoing-paint-maintenance.webp)

Navigating the financial waters of a marine painting project can feel like a complex journey, but with a clear roadmap of expenses, you can steer clear of unforeseen obstacles. Let’s dive deeper into each component, peeling back the layers to reveal what truly comprises your marine paint cost breakdown.

The Importance of a Detailed Marine Paint Cost Breakdown: Beyond the Surface?

Underestimating the full financial scope of a marine painting project can lead to costly delays and unexpected drains on your budget. Without a transparent understanding of where every dollar goes, you risk jeopardizing both your vessel’s finish and your financial stability.

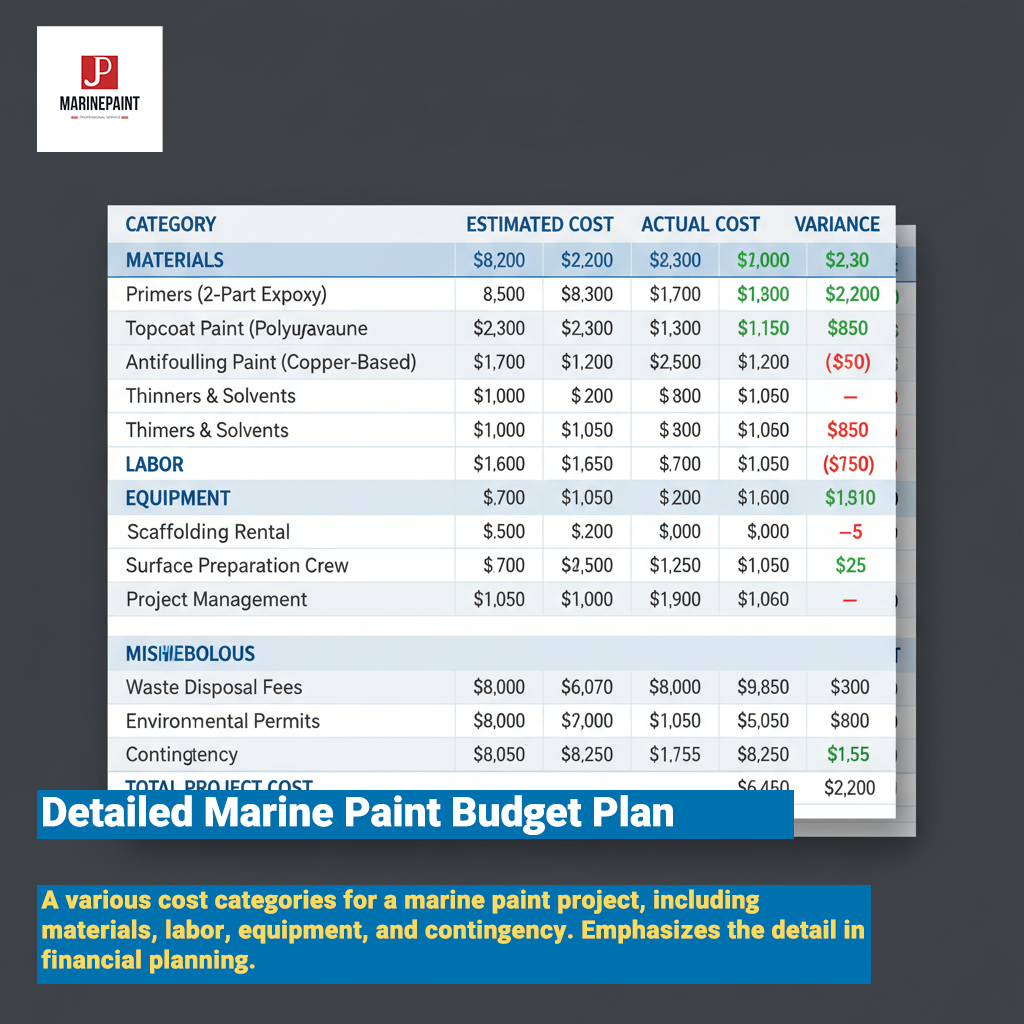

A comprehensive marine paint cost breakdown is absolutely crucial for accurate budgeting, strategic resource allocation, and preventing those unwelcome, unexpected costs in complex marine painting projects. It serves as an indispensable tool for business decision-makers, project managers, and vessel owners, enabling them to forecast expenditures effectively and ensure financial control from inception to completion. Core expenses typically fall into categories like materials, labor, equipment, and hidden costs – understanding these upfront is the first step towards a durable finish and superior asset protection.

For accurate financial management, knowing the marine paint cost breakdown involves more than just a surface-level estimate. It demands a granular understanding of each element.

Diving into the Elements of a Marine Paint Budget

| Cost Category | Key Components | Impact on Project & Budget |

|---|---|---|

| Material Costs | Primer, antifouling, topcoat, thinners, consumables | Direct correlation with vessel size, desired lifespan, and quality. |

| Labor Costs | Surface preparation, application, supervision | Varies by vessel condition, complexity, regional rates, and skill. |

| Equipment & Facility | Scaffolding, sprayers, dry dock, environmental containment | Essential for safety, efficiency, and regulatory compliance. |

| Hidden & Opportunity | Waste disposal, permits, downtime, unforeseen repairs, permits | Often overlooked, can significantly inflate final project cost. |

This detailed view helps in recognizing that quality marine painting is not merely an expense, but a strategic investment that safeguards the longevity and value of your marine assets. Successfully managing your marine paint cost breakdown begins with a thorough understanding of each variable.

Marine Paint Material Costs: Decoding the Price Per Gallon and Beyond?

Focusing solely on the price tag of a single can of marine paint can be deceptive, as it fails to account for the multiple layers and specialized formulations required for a truly protective and aesthetically pleasing finish. This narrow view often leads to unexpected expenses down the line, compromising both budget and durability.

Marine paint material costs extend far beyond the single price tag, encompassing a range of specialized coatings each with unique purposes and pricing structures. These expenses are influenced by the type of primer required to ensure adhesion and corrosion protection, the innovative technology employed in antifouling paints to prevent bio-growth, and the aesthetic and protective qualities of the topcoat. Understanding the intricacies of these individual components—from basic barrier coats to advanced self-polishing antifoulants—is crucial for an accurate marine paint cost breakdown, allowing for informed choices that balance performance, longevity, and your overall project budget.

The right materials are the backbone of a successful marine painting project. Let’s break down the key categories:

3.1. Primer Costs for Marine Applications: The Essential Foundation

Primers are not just an arbitrary first coat; they are critical barrier coats that ensure paint adhesion and protect against corrosion. JDmarine Paint Co., Ltd offers a range of high-performance primers designed for specific marine applications. For robust protection, consider options like our JDH06-4 Epoxy Zinc-Rich Anti-Rust Primer or the versatile JDH816 Grey Epoxy Primer. Factors influencing marine primer costs include the specific substrate (e.g., steel, aluminum, fiberglass), the required level of anticorrosive protection, and the brand’s reputation for quality and performance. Specialty formulations addressing specific challenges, such as our JDH838 Anti-Corrosion Primer for Galvanized Steel Sheet, will also affect the epoxy primer price. Coverage rates, typically in square feet per gallon, directly impact how much product you’ll need, influencing the overall marine paint material breakdown.

3.2. Antifouling Paint Costs: Protecting Your Marine Investment from Growth

Antifouling paint is crucial for preventing marine growth (barnacles, algae) on boat hulls, which can significantly impact vessel performance and fuel efficiency. The antifouling paint cost is influenced by its technology:

- Ablative (Self-Polishing): These paints shed microscopic layers over time, releasing biocides to prevent growth. Brands like our JD753 Tin-free self-polishing antifouling paint offer excellent, long-lasting performance.

- Hard (Non-Sloughing): These provide a durable, hard finish suitable for fast boats and frequently hauled vessels.

- Copper-Free: Environmentally friendly alternatives, often with higher initial copper-free antifouling expense.

- Biocide-Free: Emerging technologies using physical properties to deter growth.

Longevity ratings (e.g., 2-year, 3-year, 5-year) and active ingredient concentrations are major drivers of boat bottom paint price. Geographical water conditions also affect paint choice and performance, influencing the overall cost. For example, in aggressive fouling environments, a higher-performing (and often more expensive) antifouling might be a more cost-effective long-term solution. Our JD713 Chlorinated Rubber Antifouling Paint offers robust protection.

3.3. Marine Topcoat Paint Costs: Aesthetics, Durability, and Finish

The topcoat is what you see and what protects your vessel from the elements. Types include:

- Polyurethane: The most common choice for marine applications, known for exceptional durability, UV resistance, and gloss retention. Our JD908 Acrylic Polyurethane Topcoat Non-Yellowing Resistant and JD918 Acrylic Polyurethane Hull Paint (Yellowing resistance) are prime examples of high-quality polyurethane options, offering superior protection and aesthetic appeal, directly correlating with polyurethane paint cost.

- Acrylic: Good for general marine use, offering decent UV resistance and color stability.

- Enamel: More traditional, less durable than polyurethane but often more budget-friendly.

- Linear Polyester Urethane: Offers excellent gloss and color retention over extended periods.

Factors affecting marine topcoat cost include UV resistance, gloss retention, color stability, ease of application, brand reputation, and the number of coats needed to achieve the desired flawless finish. Investing in a quality topcoat is investing in the vessel’s long-term protection, aesthetic appeal, and ultimately, its resale value. For specific aesthetic needs, consider our JDB902 Acrylic Hull Paint or JDFT810 Fluorocarbon Topcoat for superior performance.

Marine Painting Labor Costs: The Human Element of Your Project Budget?

Neglecting the nuanced costs associated with skilled labor in marine painting projects is a common pitfall, severely affecting the final budget and jeopardizing the quality and longevity of the work. Without factoring in meticulous surface preparation and expert application, even the best materials will fail prematurely.

Marine painting labor costs represent a significant portion of any project budget, reflecting the highly skilled human element essential for a successful outcome. This encompasses the critical labor hours dedicated to thorough surface preparation, which forms the indispensable foundation for paint adhesion and durability, as well as the expertise involved in applying complex marine coatings with precision and efficiency. These costs fluctuate based on the vessel’s size and condition, the complexity of the job, regional labor rates, and the specialized certifications required for marine painters. Understanding these variables is key to an accurate marine paint cost breakdown, ensuring the human investment translates into a high-quality, lasting finish.

The hands-on work often determines the success of the entire project. Let’s explore the labor components:

4.1. Surface Preparation Labor Costs: The Foundation of a Lasting Marine Finish

Thorough surface preparation is paramount; it’s the cornerstone of paint adhesion, longevity, and overall finish quality. Poor preparation inevitably leads to premature paint failure, necessitating costly rework. This makes marine surface preparation cost a critical part of the marine paint cost breakdown.

Methods and associated surface prep pricing and labor hours include:

- Sandblasting / Abrasive Blasting: Highly efficient for removing old paint, rust, and scale, but requires specialized equipment, containment, and trained personnel. This method is often preferred for large commercial vessels or hulls with significant coating degradation.

- Sanding and Grinding: Involves manual labor or orbital machines for smoothing surfaces, profiling for new coatings, and feathering edges. Less intensive than blasting but can be time-consuming for large areas. Boat sanding labor varies greatly with the hull’s condition.

- Power Washing and Degreasing: Initial cleaning steps to remove dirt, grime, and contaminants. Essential groundwork before any abrasive work.

- Fairing and Filling: Repairing imperfections, osmotic blisters, or structural damage beneath the surface. This can add significant marine fairing expense and labor hours due to the precision and multiple layers required to achieve a perfectly smooth hull.

Factors influencing these labor hours include the size and type of vessel, the current condition of the surface (e.g., heavily fouled, severely peeling paint, existing damage), and the extent of repair needed.

4.2. Application Labor Costs: Expert Marine Paint Application Pays Off

The application of marine coatings requires precision and expertise, directly impacting the final finish and durability. This is where the marine paint application cost comes into play.

- Application Methods and Labor Impact:

- Brush and Roller: Suitable for smaller jobs, touch-ups, or intricate areas. Generally less labor-intensive per hour but slower for large surfaces.

- Conventional Spray: Offers a good balance of speed and finish quality for experienced applicators.

- Airless Spray: The most common method for large areas, enhancing speed and efficiency for skilled operators. However, it requires significant skill to prevent runs, sags, and ensure even film thickness, which translates to competitive professional marine painter fees.

- Labor Rates: These vary significantly by region, the painter’s experience, and specific certifications (e.g., for hazardous materials, confined spaces). Highly skilled marine painters command higher rates but deliver superior results, reducing the likelihood of rework.

- Factors influencing application time: The number of coats required (primer, tie-coat like our JDH263 Epoxy Tie Coat, antifouling, topcoat), the complexity of the vessel’s contours, prevailing weather conditions (temperature, humidity, wind), and crucial drying times between coats. These elements all contribute to the overall marine painting estimate.

Equipment and Facilities Costs: Essential Overheads in Marine Painting?

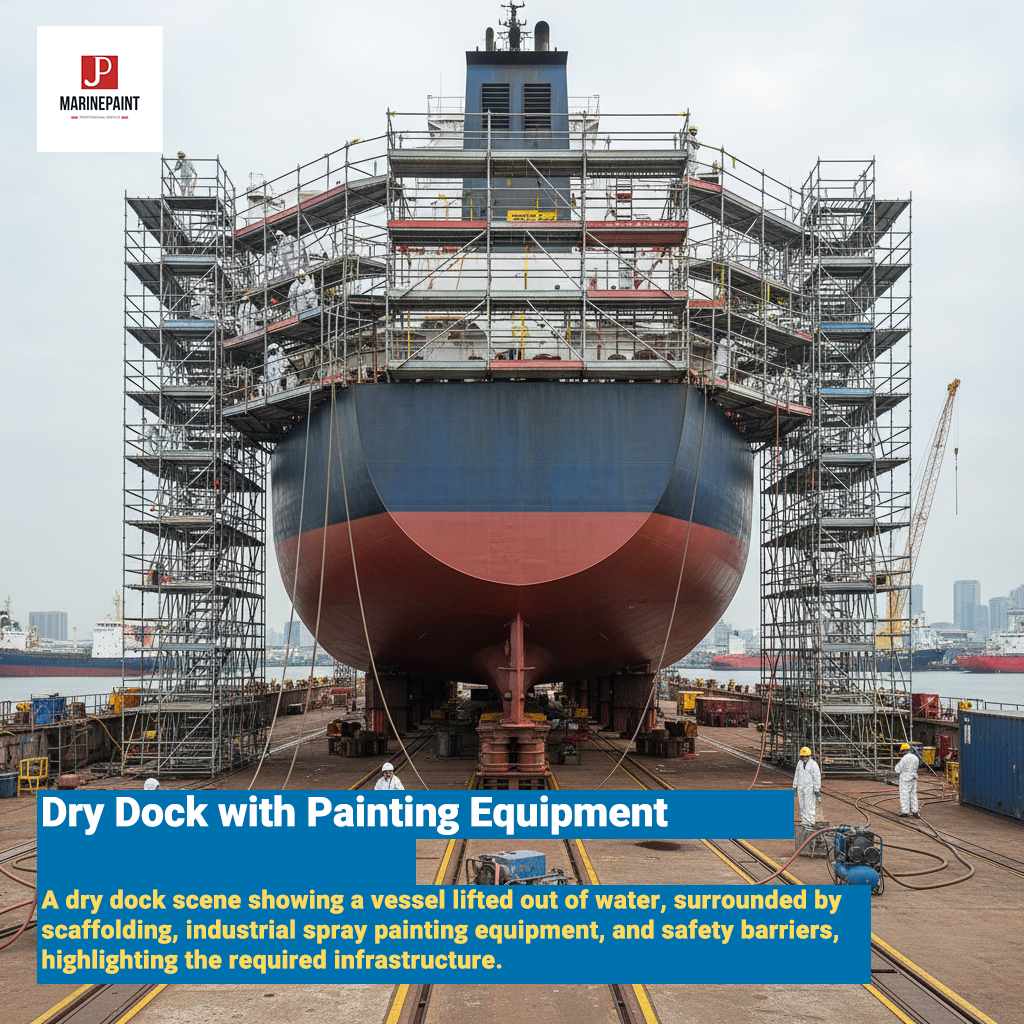

Overlooking the significant impact of equipment rental and facility usage fees can quickly bloat a marine painting budget, turning an initial estimate into a costly surprise. These essential overheads are not optional; they are critical for safety, efficiency, and environmental compliance.

Equipment and facilities costs are non-negotiable overheads in marine painting projects, encompassing everything from the specialized tools required for proper paint application and safety to the critical infrastructure needed for working on a vessel out of water. These expenses include scaffolding for safe access, sophisticated spray equipment for professional finishes, and indispensable safety gear for workers. Furthermore, dry dock or boatyard rental fees, alongside environmental containment systems, are essential for compliance and project execution. A thorough accounting of these elements is a vital part of the marine paint cost breakdown, ensuring the project is executed efficiently, safely, and compliantly.

These costs are often substantial but necessary for a compliant and successful project.

5.1. Required Equipment Costs for Marine Painting Projects

- Scaffolding and Staging: Essential for safe access to all areas of the hull. These can be rented or purchased, with rental costs based on duration.

- Spray Equipment: Includes airless sprayers, conventional spray guns, hoses, and compressors. Maintenance, rental, or purchase costs are significant.

- Safety Gear and Environmental Controls: Personal Protective Equipment (PPE) such as respirators, coveralls, gloves, and eye protection are mandatory. Marine safety gear cost is continuous. Environmental controls like containment sheeting, ventilation systems, and dehumidifiers are critical for overspray control and optimal drying.

- Specialized Tools: Grinders, sanders, vacuum systems for dust extraction, and other power tools are fundamental. This contributes to the overall marine paint equipment cost.

5.2. Facility and Dock Rental Costs

- Dry Dock or Boatyard Rental: Imperative for out-of-water work. Rates are typically daily or weekly and include potentially substantial haul-out and launch fees, contributing to the total boatyard fees.

- Environmental Enclosures/Containment: Often mandated by regulations, these structures control overspray and volatile organic compound (VOC) emissions, adding to the environmental containment expense.

- Utilities: Electricity and water usage during the project and for crew welfare.

Hidden and Opportunity Costs: Overlooked Factors in Your Marine Paint Budget?

Failing to account for unforeseen expenses and the revenue lost during a vessel’s downtime can severely distort the actual cost of a marine painting project, leading to significant financial setbacks that were not initially budgeted. This blind spot can undermine an otherwise meticulously planned budget.

Hidden and opportunity costs are often the quietly lurking expenses that can dramatically inflate a marine paint cost breakdown, transforming a reasonable estimate into an unforeseen burden. These frequently overlooked factors include the specialized disposal of hazardous waste materials, the acquisition of various permits and environmental compliance fees, and the significant financial impact of vessel downtime—which translates directly into lost revenue for commercial operations. Furthermore, the potential for unexpected repairs discovered during surface preparation necessitates a prudent contingency budget to absorb these shocks. Ignoring these elements introduces substantial financial risk and undermines thorough project planning.

These less obvious, yet essential, cost components demand careful consideration.

6.1. Waste Disposal Costs

- Hazardous waste: Old paint chips, solvents, and contaminated rags require specialized, often regulated, disposal. This contributes significantly to marine paint waste cost.

- Permitting and Environmental Fees: Local, state, and federal regulations regarding hazardous waste and emissions can incur significant environmental compliance fees.

6.2. Downtime and Opportunity Costs

- Lost revenue: For commercial vessels, time out of service means lost charter fees, cargo revenue, or operational uptime. This is a critical boat downtime cost.

- Extended project timelines: Unexpected delays due to weather, material shortages, or labor issues can inflate overall project costs.

- Logistics and inconvenience: Costs associated with relocating the vessel, crew accommodation, and project management time. These constitute the opportunity cost marine painting.

6.3. Unexpected Repairs and Contingency

- Unforeseen damage: Discovering hull damage, osmotic blisters (especially relevant for fiberglass boats), or structural issues during surface preparation is common and will lead to unplanned marine repair costs.

- Contingency budget: It is prudent to allocate 10-15% of the total budget for unforeseen expenses. This painting contingency budget acts as a crucial safety net.

How to Optimize Your Marine Paint Cost Breakdown: Strategies for Savings?

Approaching a marine painting project without a clear strategy for cost optimization can lead to unnecessary expenditures and compromise the long-term value of your investment. Simply choosing the cheapest option often results in higher costs in the long run.

Optimizing your marine paint cost breakdown is about smart, strategic choices, not just cutting corners. Key strategies include meticulous project planning and careful material sourcing to prevent waste and ensure the right products are chosen for longevity. Implementing preventative maintenance, like regular cleaning and minor touch-ups, can significantly extend the life of your paint job, delaying major recoating projects and thus saving on boat painting expenses. Crucially, selecting a reputable contractor ensures efficiency, quality, and reduces the likelihood of costly rework. Ultimately, investing in quality materials—such as JDmarine Paint Co., Ltd’s high-performance coatings—and skilled labor upfront often leads to greater durability and fewer recoating expenses over time, providing long-term savings.

Conclusion: Mastering Your Marine Paint Cost Breakdown for Project Success

Mastering your marine paint cost breakdown is truly the cornerstone of effective asset management and successful project execution. This article has illuminated the complex interplay of material, labor, equipment, and hidden costs that collectively define your total investment.

A thorough understanding of all these components empowers business decision-makers and vessel owners to budget accurately, select the most appropriate materials and professional services, and ultimately ensure a durable, high-quality finish for their marine assets. We encourage you to utilize this comprehensive breakdown as an invaluable guide for your next marine painting project, securing both the aesthetic integrity and long-term protection of your vessel.

![]()