Competitive Advantage in Maritime: Leveraging Fuel-Saving Coatings for Market Leadership & Cost Control

In today’s highly competitive global shipping market, fuel costs and increasingly stringent environmental regulations are squeezing shipowners and operators in unprecedented ways.

Are you seeking a strategic investment that not only cuts costs but also enhances your market position? Ignoring vessel efficiency means your operating costs will continue to rise, and your market competitiveness will steadily decline.

The core strategy for addressing these challenges lies in deploying advanced fuel-saving vessel coatings. These coatings significantly reduce fuel consumption by inhibiting biofouling and optimizing hull smoothness to reduce hydrodynamic drag, making them key to achieving operational efficiency and environmental compliance. This article will explore how fuel-saving vessel coatings can provide a significant competitive advantage in the maritime industry by reducing operating costs, improving vessel availability, enhancing charter attractiveness, and promoting environmental sustainability, helping you stand out in the market.

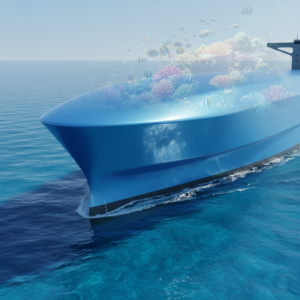

Title: Striving for Excellence: Realizing the Future of Ship Fuel Efficiency

Description: A cargo ship’s hull remaining clean and smooth while sailing at sea symbolizes fuel efficiency achieved through advanced coatings.

Understanding the science behind **fuel-saving ship coatings** is the first step in turning them into your strategic asset. Next, we’ll reveal how these coatings fundamentally change the operational efficiency of ships.

Understanding Fuel-Saving Marine Coatings: The Science Behind Efficiency Improvements

When ships sail at sea, their hulls inevitably become covered with various marine organisms, from microorganisms to barnacles and algae—a phenomenon known as biofouling. These deposits significantly increase the roughness of the hull, leading to a sharp increase in frictional drag between the ship and the water. This additional drag means that ships need to consume more fuel to maintain the same speed, directly resulting in soaring operating costs and increased environmental impact. Traditional coatings often fail to provide long-term effective protection against biofouling, thus trapping ships in a high-fuel-consumption dilemma.

Fuel-saving marine coatings were developed to address this core problem. They reduce drag and improve fuel efficiency through two main mechanisms.

First, antifouling coatings, especially long-lasting self-polishing antifouling paints, can continuously release bioactive substances, effectively preventing marine organisms from adhering to the hull surface [2][7][9][18]. For example, JDmarine’s JD753 self-polishing antifouling paint [18] and JD744 chlorinated rubber antifouling paint [2] maintain the smoothness of the hull by continuously releasing bactericides to keep the bottom and underwater facilities free from contamination. Second, even without biofouling, the smoothness of the coating itself is crucial. Ultra-smooth hull surfaces can significantly reduce hydrodynamic drag, meaning that ships require less propulsion to reach or maintain the required speed, thereby directly reducing fuel consumption. For example, JDL44-83 bituminous antifouling paint [9] also helps keep the hull smooth due to its ease of application and strong adhesion, thus achieving fuel savings.

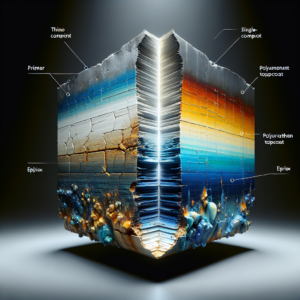

Title: Biofouling vs. Clean Hull: A Look at the Drag Difference

Description: This comparison shows the drag difference between a hull heavily contaminated with marine organisms and a clean hull coated with antifouling paint.

Types of fuel-saving coatings

Fuel-saving marine coatings are mainly divided into several categories:

- Self-polishing copolymer (SPC) antifouling paint:Through a controlled dissolution mechanism, it continuously releases bioactive substances while maintaining the microscopic smoothness of the hull surface. JDmarine’s JD753 Wuxi self-polishing antifouling paint [18] belongs to this category, effectively preventing marine organisms from attaching and resisting seawater erosion and alternating wet and dry conditions.

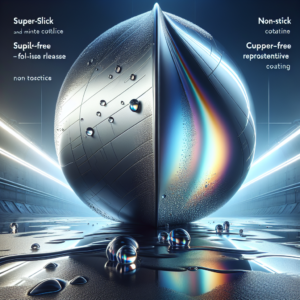

- Fluorosilane/silicone type release antifouling paint:Through the formation of an ultra-smooth, low surface energy coating, it makes it difficult for marine organisms to attach.

It adheres or is easily washed away by water flow, contains no bactericide, and is more environmentally friendly. - Ultra-low friction coatings:Aimed to minimize the micro-roughness of the hull surface, thereby reducing hydrodynamic resistance.

- Traditional antifouling paints:Such as chlorinated rubber antifouling paints, which prevent biofouling by continuously releasing bactericides. For example, JDmarine’s JD744 chlorinated rubber antifouling paint [2] and JD713 chlorinated rubber antifouling paint [7], can effectively prevent marine organisms from adhering and keep the bottom of the ship clean.

Lowering Operating Costs: The Direct Economic Impact of Fuel-Saving Coatings

For shipping companies, fuel costs typically account for 40% to 60% of operating costs. Therefore, any measure that significantly reduces fuel consumption will bring huge economic benefits. Relying solely on traditional coatings to combat rising fuel costs and environmental penalties is insufficient. If your fleet spends millions annually on fuel, even a 5%-10% saving can directly impact your company’s profitability. Neglecting this critical area will allow your competitors to gain a market advantage with lower shipping costs.

Fuel-saving marine coatings directly result in substantial fuel savings by preventing biofouling and reducing hydrodynamic drag. According to industry reports and research, the use of advanced fuel-saving marine coating systems can significantly reduce ship fuel consumption by 5% to 20%. This means that hundreds of thousands or even millions of dollars in fuel expenses can be saved annually. This direct fuel cost reduction is one of the most effective ways to achieve financial optimization. In addition, the reduction in fuel consumption also directly means a reduction in greenhouse gas emissions, which not only helps to comply with increasingly stringent environmental regulations such as the IMO’s EEXI (Existing Ship Energy Efficiency Index) and CII (Carbon Intensity Index), but also avoids potential carbon taxes or penalties, further controlling costs. For example, choosing JDmarine’s self-polishing antifouling paint, such as JD753 Wuxi self-polishing antifouling paint [18], not only provides long-lasting antifouling protection, but also brings significant fuel savings and environmental benefits to ship owners by maintaining the smoothness of the hull.

Title: Fuel Economy Dashboard: Visually Presenting Cost Savings and Environmental Benefits

Description: A dashboard chart showing reduced fuel consumption, reduced carbon emissions, and cost savings.

Extended Dry-Docking Intervals and Maintenance Savings

Advanced fuel-saving marine coatings, such as JDmarine’s Long-Lasting Antifouling Coating, typically offer superior durability and lifespan. They are effective against biofouling for up to 5 years or more, significantly extending the intervals between dry-docking. This means shipowners can reduce the need for frequent hull cleaning and repainting, saving substantial dry-docking costs, labor costs, and lost revenue due to downtime.

Improved Vessel Performance and Speed Maintenance for Optimized Operations

A clean, smooth hull allows vessels to maintain desired speeds with less power. This is particularly beneficial for liner shipping, where adherence to sailing schedules is crucial. By optimizing sailing times, fuel-efficient vessel coatings help improve schedule reliability, thereby enhancing customer satisfaction and operational efficiency.

Increasing Vessel Availability and Uptime: Maximizing Maritime Asset Utilization

In the maritime industry, every day a vessel is out of service means a significant loss of revenue. Frequent dry-docking, underwater cleaning, and unexpected performance issues directly reduce the time your fleet spends creating value at sea. If you fail to fully utilize your vessel assets, your return on investment will be significantly reduced. Efficient fleet management requires minimizing non-productive time, and traditional coating systems are often a stumbling block to this goal.

Long-lasting fuel-saving marine coating systems can significantly extend dry-docking intervals, directly meaning more operational time for vessels.

For example, JDmarine’s JD753 Wuxi self-polishing antifouling paint [18] and other products have long-lasting antifouling properties that ensure the hull remains clean for a longer period of time, thereby reducing the frequency and necessity of underwater hull cleaning. Less cleaning needs mean that ships can spend more time at sea transporting goods or performing tasks, directly increasing revenue generation capacity.

Title: Vessel Uptime: The Results of Strategic Coating Investments

Description: The comparison chart shows how vessels using long-lasting coatings extend their uptime and reduce dry-docking.

Reliability and Performance Consistency: A Hallmark of Fuel-Efficient Vessel Operations

By continuously preventing biofouling, fuel-efficient vessel coatings ensure the stability and predictability of hull performance. This consistent performance reduces unexpected speed drops or fuel consumption due to fouling, thus avoiding potential operational disruptions and delays. JDmarine’s premium coatings, such as JD918 Acrylic Polyurethane Hull Paint (Yellowing Resistant) [3] or JDB902 Acrylic Hull Paint [12] for the hull above the waterline and superstructure, have excellent adhesion, weather resistance and color and gloss retention, further ensuring the long-term stability of the overall hull appearance and performance.

Strategic Fleet Management and Enhanced Scheduling Flexibility

Increased vessel availability gives fleet managers greater scheduling flexibility. They can plan routes more effectively, optimize vessel deployments, and seize unexpected market opportunities without worrying about availability issues caused by hull maintenance. This strategic advantage is crucial for remaining competitive in the dynamic global shipping market.

Enhancing Chartering Attractiveness and Market Leadership: Standing Out in the Global Shipping Market

In an increasingly transparent and competitive global shipping market, shipowners and operators must find differentiated advantages to attract high-value charterers. Simply offering a seaworthy vessel is no longer enough.

Today’s charterers, especially those with corporate social responsibility (CSR) goals and a strong focus on cost control, proactively seek vessels that offer both economic and environmental benefits. Failing to demonstrate this forward-thinking approach will leave your fleet undervalued by competitors, missing out on better charter rates and long-term partnerships.Fuel-saving marine coatings are a powerful magnet for attracting quality charterers. With continued fluctuations in fuel costs and increasingly stringent environmental regulations (such as the IMO’s EEEXI/CII indices), charterers are increasingly inclined to charter vessels with proven fuel efficiency. A vessel equipped with advanced fuel-saving marine coatings translates to lower voyage costs, resulting in direct economic benefits for the charterer. This proven fuel efficiency enables shipowners to demand higher charter rates in the market or stand out in competitive bidding processes, securing more attractive contracts. Furthermore, the proactive adoption of fuel-saving marine coatings demonstrates a shipowner’s strong commitment to environmental responsibility. This not only aligns with the global trend of sustainable development but also responds to the requirements of regulatory bodies such as the International Maritime Organization (IMO Environmental Regulations), thereby enhancing the company’s brand reputation and corporate social responsibility (CSR) image. For example, JDmarine’s JD918 Acrylic Polyurethane Hull Paint (Yellowing Resistant) [3] and JD918 Acrylic Polyurethane Hull Paint (Yellowing Resistant) [3] are examples of this.product/jdft810-fluorocarbon-topcoat/”>JDFT810 fluorocarbon topcoat [23] Not only does it provide excellent protection for the hull above the waterline, but its excellent color and gloss retention also indirectly supports the ship’s image, helping the fleet to meet market tests in the best condition.

Title: How Fuel Efficiency Enhances Ship Chartering Attractiveness

Description: The infographic shows how fuel efficiency attracts charterers and brings lower costs, environmental compliance, and enhanced brand reputation.

![]()