Maximizing Marine Coatings ROI: Are Your Vessels Truly Optimized for Profit?

In the maritime world, every penny counts. Marine coatings ROI isn’t just about the initial purchase price; it’s a strategic investment that profoundly impacts your vessel’s entire operational lifecycle. Smart choices here directly translate to enhanced profitability.

Understanding Marine Coatings ROI means looking beyond the sticker price and embracing a holistic view of vessel performance. High-performance marine coatings are crucial for reducing ship operating costs, extending vessel lifespan, and ultimately, boosting your bottom line. They directly contribute to fuel consumption reduction, minimized maintenance costs, and improved asset preservation, making them an indispensable component of strategic asset management in the global shipping industry. For ship owners and operators, prioritizing investment in advanced coating systems is not an option, but a strategic imperative to drive long-term value and ensure vessel profitability.

![[Image Placeholder]**Image Title:** Igniting Profit: The Power of Marine Coatings ROI**Image Description:** A dynamic image showing a vessel sailing efficiently across calm waters, leaving a minimal wake. Overlayed are glowing digital lines and graphs representing increasing fuel efficiency, reduced maintenance, and enhanced asset value, all pointing towards a large, illuminated [Image Placeholder]**Image Title:** Igniting Profit: The Power of Marine Coatings ROI**Image Description:** A dynamic image showing a vessel sailing efficiently across calm waters, leaving a minimal wake. Overlayed are glowing digital lines and graphs representing increasing fuel efficiency, reduced maintenance, and enhanced asset value, all pointing towards a large, illuminated](https://jdmarinepaint.com/wp-content/uploads/2025/09/igniting-profit-the-power-of-marine-coatings-roi.png)

Let’s dive deeper into how superior marine coatings translate into tangible financial returns, transforming operational challenges into significant economic benefits.

Deciphering Marine Coatings ROI: A Holistic View of Operational Savings?

Are spiraling fuel bills and frequent dry-docking eating into your profits? The hidden costs of sub-optimal vessel performance can be staggering, but proactive investment in quality marine coatings offers a powerful antidote, directly enhancing your Marine Coatings ROI.

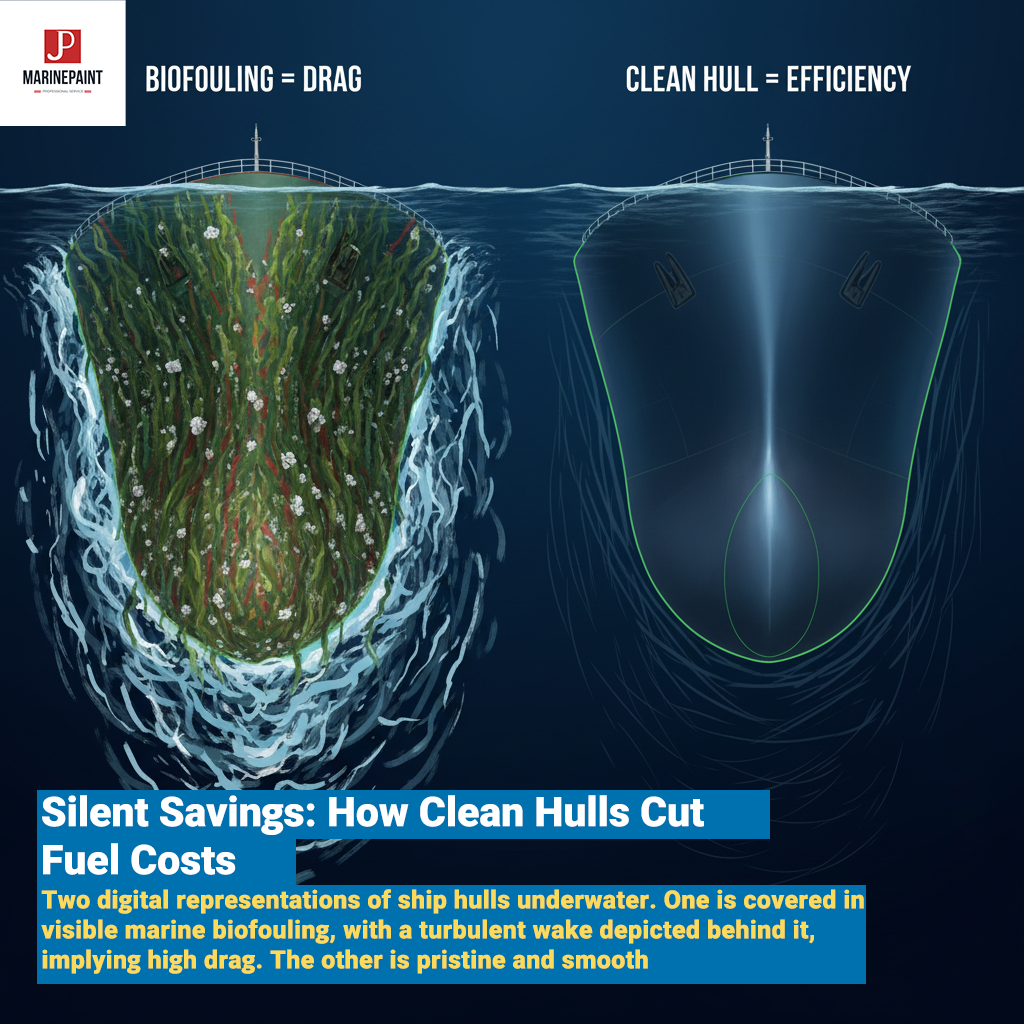

The most significant impact on Marine Coatings ROI comes from fuel efficiency. A smooth hull reduces hydrodynamic drag, meaning less power is required to maintain speed, leading to substantial fuel consumption reduction. Whether through advanced antifouling solutions like our JD753 Tin-free self-polishing antifouling paint, or cutting-edge foul release technologies, the long-term fuel savings are immense. Quantifying this reduction through superior coatings is paramount for ship profitability, directly affecting ship operating costs and contributing to lower carbon emissions reduction shipping.

Beyond fuel, significant maintenance cost reductions through Marine Coatings ROI are evident. High-performance antifoulings and corrosion protection marine systems minimize the need for frequent hull cleaning and extend dry-docking intervals. This not only saves on labor and material costs associated with spot repairs and patch-ups but also reduces expensive vessel downtime. JDmarine’s corrosion protection systems, such as our High-Build Epoxy Coating (e.g., JDH835 Aluminum Iron Epoxy Anti-Rust Paint), are designed to extend coating lifespans, slashing maintenance costs and boosting overall operational efficiency. These advanced coating systems directly impact a vessel’s total cost of ownership (TCO) marine by preserving asset value through preventing structural degradation and metal fatigue, aligning with smart ship maintenance strategies.

Maximizing Fuel Efficiency: The Hydrodynamic Advantage

Hydrodynamic performance is the bedrock of maritime fuel efficiency. A clean, smooth hull significantly reduces resistance in water, translating directly into lower fuel consumption. This reduction is not just marginal; studies consistently show that effective hull efficiency strategies, largely driven by advanced coatings, can lead to substantial savings.

- Antifouling Coatings: These coatings prevent the attachment and growth of marine organisms (biofouling prevention) on the hull. Traditional antifoulings release biocides, but modern self-polishing copolymers (SPC) like those in our range, such as JD753 Tin-free self-polishing antifouling paint, offer a controlled release, maintaining a smoother surface over longer periods.

- Foul Release Coatings: Representing the future of eco-friendly Marine Coatings ROI, these silicone-based coatings create a low surface energy surface that biofouling struggles to adhere to, or is easily dislodged by the vessel’s movement. They are particularly effective for active vessels, ensuring optimal hull efficiency without biocides.

| Coating Type | Primary Benefit | Fuel Savings Potential | Environmental Impact | Key Application Area |

|---|---|---|---|---|

| SPC Antifouling | Biofouling prevention | High (through smoothness) | Moderate | Most vessel types, various speeds |

| Foul Release | Easier biofouling release | Very High (sustained) | Low | High-activity vessels, faster speeds |

| Corrosion Protection | Structural integrity | Indirect (prevents rough surfaces) | Low | All steel hulls, critical areas |

Quantifying fuel consumption reduction involves rigorous performance monitoring marine vessels, utilizing speed-power curves and fuel flow meters. By comparing data before and after coating application, the direct financial benefits become clear, highlighting the investment in marine coatings. This data-driven approach solidifies the Marine Coatings ROI argument, transforming speculative savings into measurable economic benefits marine coatings.

Extending Vessel Lifespan and Asset Value: A Core Marine Coatings ROI Benefit?

Is your vessel’s long-term value eroding due to the silent threats of corrosion and degradation? Beyond immediate operational savings, strategic coating investments offer a profound impact on your asset’s longevity, making Marine Coatings ROI a key player in preserving capital.

Corrosion protection and the lifespan of marine assets are inextricably linked, forming a cornerstone of Marine Coatings ROI. Preventing structural degradation and metal fatigue is vital for vessel integrity and safety. Our specialized anti-corrosive primers, like JDH06-4 Epoxy Zinc-Rich Anti-Rust Primer, combined with robust topcoats, create an impenetrable barrier against harsh marine environments, extending service intervals significantly. This meticulous attention to detail ensures your valuable assets remain operational and structurally sound for years to come, directly impacting lifecycle cost analysis and ship profitability.

Preserving asset value with strategic Marine Coatings ROI also involves maintaining aesthetic appeal and market value. A well-maintained vessel with high-quality coatings signals reliability and care, enhancing its resale or charter rates. Furthermore, compliant coatings ensure adherence to regulatory standards and inspections, avoiding costly penalties and delays. Think of our durable polyurethane topcoats, such as JD908 Acrylic Polyurethane Topcoat Non-Yellowing Resistant, which not only provide excellent protection but also maintain a pristine finish, contributing directly to asset preservation and strategic asset management. Investing in advanced coating systems like sophisticated marine paint technologies ensures your fleet remains competitive and compliant with IMO guidelines, safeguarding your investment against premature depreciation.

Comparing Coating Solutions for Optimal Marine Coatings ROI?

With a myriad of marine coating options available, are you confident in selecting the solution that truly maximizes your Marine Coatings ROI? The right choice demands a deep understanding of each coating’s implications for performance, durability, and environmental impact.

The types of marine coatings and their ROI implications vary significantly. Traditional antifouling coatings, while effective, often have leaching rates and environmental impacts that are now under scrutiny. Next-gen solutions, like foul release coatings, are increasingly favored for their low surface energy, self-cleaning properties, and extended durability, offering a superior Marine Coatings ROI through reduced maintenance and improved ecological profiles. For corrosion protection marine, systems like epoxy, polyurethane, and zinc-rich primers (such as JDH819 Epoxy Zinc Phosphate Primer) provide long-term barrier protection and abrasion resistance, crucial for vessel lifespan extension. Specialty coatings, such as ice release or anti-graffiti options, offer niche ROI benefits for specific operational profiles.

Factors influencing coating choice and Marine Coatings ROI are diverse. Vessel type, operating profile, and geographical routes dictate the most suitable solution. Environmental regulations shipping, particularly IMO guidelines, increasingly push for sustainable marine coatings, which, while sometimes having a higher initial cost, often yield better long-term ROI through compliance and reduced environmental impact. A thorough total cost of ownership (TCO) analysis, weighing initial coating application costs against prolonged performance and savings, is essential for making informed decisions. Our technical consultants at JDmarine Paint Co., Ltd are experts in guiding you through these choices, ensuring you select high-performance antifoulings and advanced coating systems that align with your specific hull efficiency and ship operating expenses (OPEX) goals.

Calculating Your Marine Coatings ROI: A Practical Framework?

Feeling overwhelmed by the array of numbers when evaluating coating options? Without a clear framework, calculating your Marine Coatings ROI can seem daunting, leaving you unsure if your investment truly pays off.

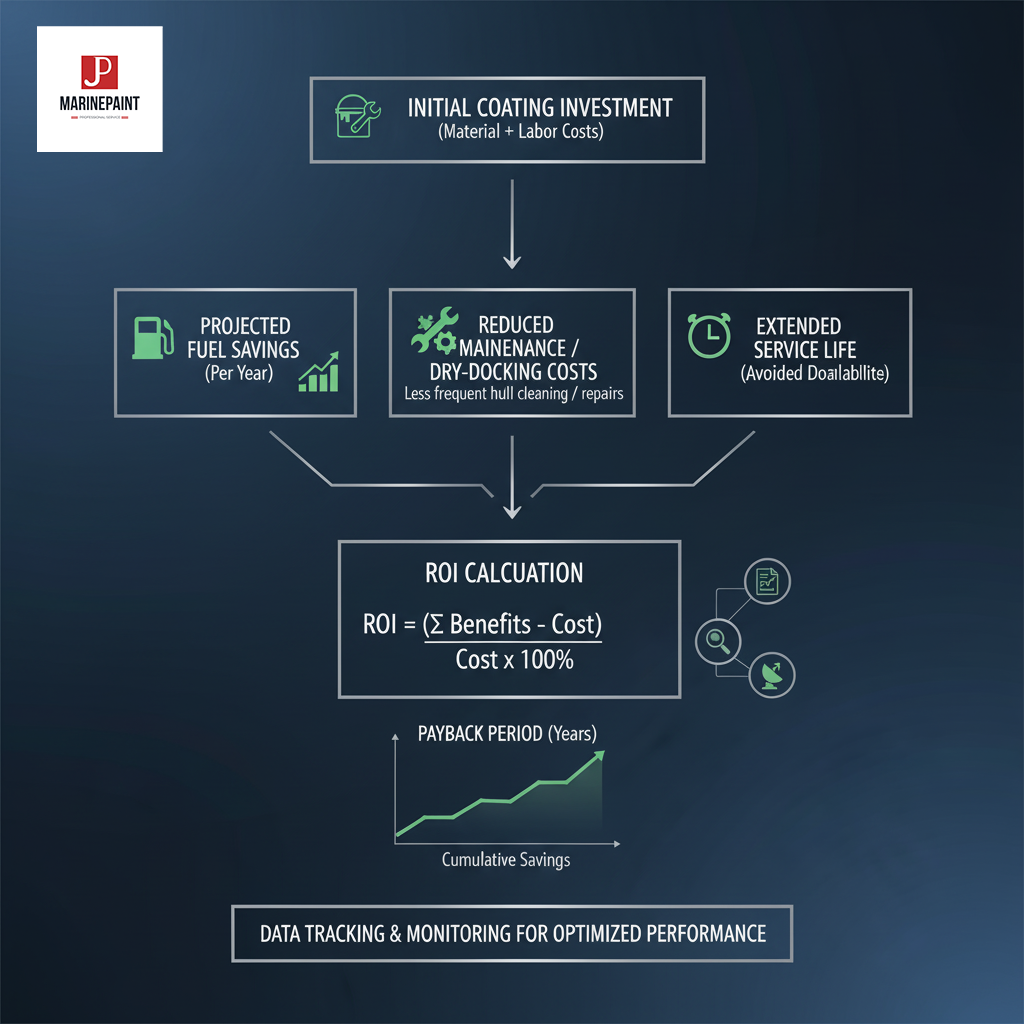

To truly understand Marine Coatings ROI, you need a practical framework. It starts with key metrics: initial coating application costs (materials + labor), projected fuel savings per year (a significant factor in hull efficiency and fuel consumption reduction), reduced dry-docking and maintenance costs per cycle, and extended service intervals that minimize avoided downtime. Consider the expected coating lifespan versus replacement costs. For instance, investing in a durable JDmarine anti-corrosive system may have a higher upfront cost but dramatically extends the period before reapplication is needed, significantly improving return on investment shipping by deferring future expenses.

Developing a simple ROI model for marine coatings investment involves analyzing the payback period, which shows how quickly your investment is recouped. Furthermore, considering Net Present Value (NPV) helps assess the long-term value, accounting for the time value of money. The importance of data tracking and performance monitoring cannot be overstated; accurate records of fuel burn rates, maintenance cycles, and hull cleaning reduction provide the concrete evidence needed to validate your Marine Coatings ROI. This meticulous approach to lifecycle cost analysis empowers you with the insights to make data-driven decisions for vessel performance optimization and increased ship profitability.

The Future of Marine Coatings and Sustained ROI

The maritime industry is constantly evolving, and so too are the innovations in coating technology for enhanced Marine Coatings ROI. Bio-mimicry, self-healing coatings, and even robotic application promise even greater efficiencies and reduced human intervention. Environmental compliance and green Marine Coatings ROI are no longer buzzwords but drivers of innovation, aligning with IMO guidelines and pushing for carbon emissions reduction shipping. Strong partnerships with coating manufacturers like JDmarine are crucial, ensuring you benefit from optimized performance, value, and access to cutting-edge solutions that cater to demanding applications.

Conclusion: Elevating Profitability Through Marine Coatings ROI

High-quality marine coatings are indispensable, acting as a powerful lever for vessel performance optimization. Invest wisely in advanced coating systems for superior Marine Coatings ROI and unlock significant long-term profitability.

FAQs on Marine Coatings ROI

Q1: How often should marine coatings be reapplied to maximize ROI?

A1: Reapplication frequency varies, depending on the coating type (e.g., traditional antifouling vs. foul release), vessel activity, operating environment, and manufacturer recommendations. High-performance coatings, like those from JDmarine, often extend intervals, improving Marine Coatings ROI.

Q2: Are eco-friendly marine coatings truly cost-effective in terms of ROI?

A2: Absolutely. While initial costs might be higher, eco-friendly options offer long-term benefits through enhanced fuel efficiency, reduced environmental impact, regulatory compliance, and potential market advantages, leading to a strong Marine Coatings ROI.

Q3: What’s the typical payback period for investing in premium marine coatings?

A3: The payback period can range from a few months to a couple of years, largely depending on the vessel’s operating profile, fuel costs, and the specific coating’s performance. Significant fuel consumption reduction often accelerates the Marine Coatings ROI.

Q4: How do I measure the actual fuel savings from my new marine coatings?

A4: You can measure fuel savings using methods like speed-power curve analysis, installing fuel flow meters, and utilizing advanced performance monitoring systems that track vessel performance optimization over time.

Q5: Can existing coatings be upgraded, or is a full blast and paint always required for better ROI?

A5: It depends on the existing coating’s condition, type, and compatibility. Sometimes, overcoating or spot repairs are feasible. However, a full surface preparation marine and new application often yield the best long-term Marine Coatings ROI.

![]()