A ship’s greatest battle against corrosion happens unseen, deep within its ballast tanks. This unseen guardian is your primary defense, fundamental to the vessel’s structural longevity and operational safety.

Ensuring your vessel’s longevity starts with a high-performance ballast tank coating system. This isn’t just paint; it’s a specialized protective barrier engineered to withstand the harsh, corrosive environment inside ballast tanks. A properly selected and applied coating, compliant with IMO PSPC standards, prevents steel wastage, pitting, and structural failure. The goal is a 15-year service life, which is achieved through meticulous surface preparation (Sa 2.5), correct application of a durable system like a two-component epoxy, and adherence to specified dry film thickness (DFT). This comprehensive approach to corrosion protection is non-negotiable for maintaining the asset’s value, ensuring crew safety, and guaranteeing regulatory compliance.

![[Image Placeholder]> **Image Title:** Inside the Belly of the Ship: A Newly Coated Ballast Tank> **Image Introduction:** The gleaming, light-colored surface of a freshly coated ballast tank, highlighting the seamless protective barrier crucial for a vessel's structural integrity.> **Prompt:** A wide-angle, high-resolution photograph from inside a massive ship's ballast tank. The tank has just been coated with a light grey, high-gloss epoxy paint. The lighting is bright and even, revealing the complex geometry of steel beams, welds, and frames. The surface is flawless, emphasizing the quality of the marine coating application. [Image Placeholder]> **Image Title:** Inside the Belly of the Ship: A Newly Coated Ballast Tank> **Image Introduction:** The gleaming, light-colored surface of a freshly coated ballast tank, highlighting the seamless protective barrier crucial for a vessel's structural integrity.> **Prompt:** A wide-angle, high-resolution photograph from inside a massive ship's ballast tank. The tank has just been coated with a light grey, high-gloss epoxy paint. The lighting is bright and even, revealing the complex geometry of steel beams, welds, and frames. The surface is flawless, emphasizing the quality of the marine coating application.](https://jdmarinepaint.com/wp-content/uploads/2025/09/the-gleaming-light-colored-surface-of-a-freshly-coated-ballast-tank-highlighting-the-seamless-protective-barrier-crucial-for-a-vessels-structural-integrity.png)

This guide will walk you through every critical aspect of ballast tank coating, from choosing the right system to understanding the regulations that govern it. Let’s dive into how you can protect your most valuable asset from the inside out.

What is a Ballast Tank and Why is Coating So Crucial?

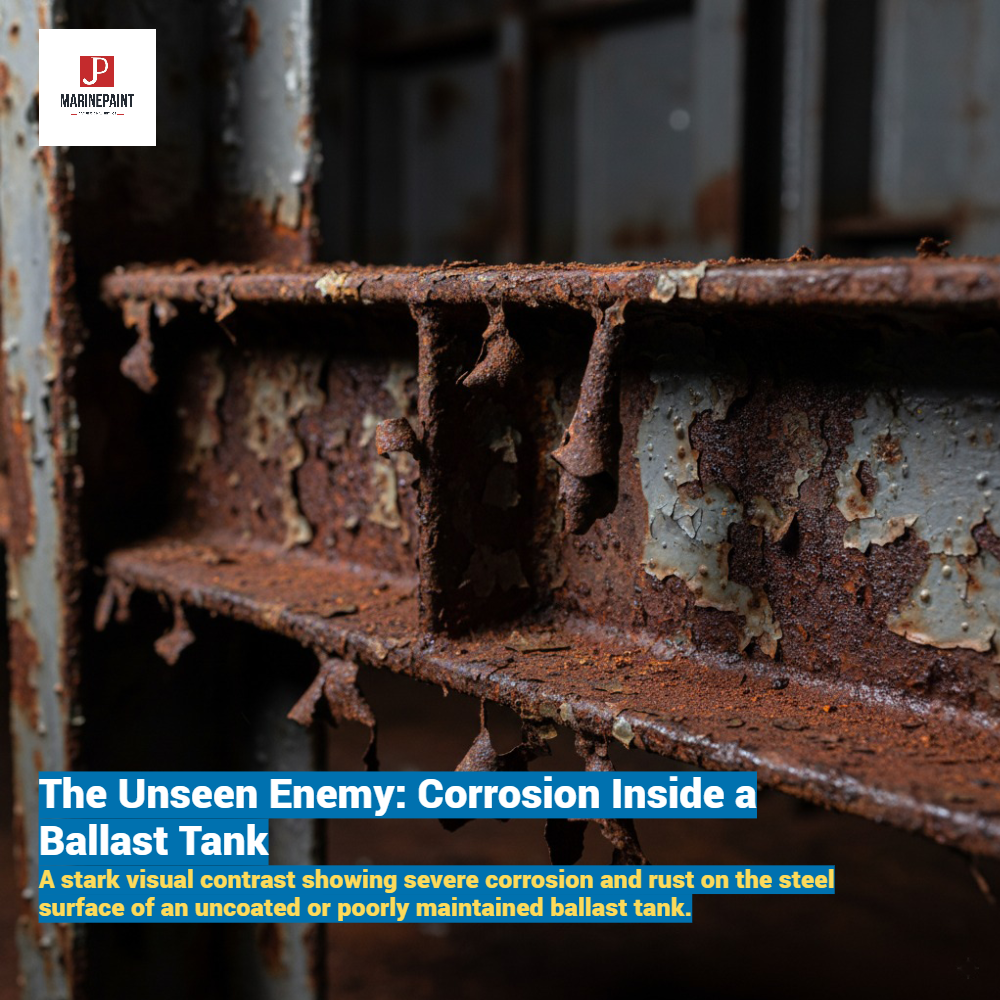

The continuous cycle of saltwater, humidity, and atmospheric changes within your ballast tanks creates a perfect storm for aggressive corrosion. Leaving this environment unprotected is not an option, as it can lead to catastrophic structural failures, costly repairs, and significant downtime, directly impacting your vessel’s safety and profitability.

The primary role of a ballast tank coating is corrosion prevention. Ballast tanks are essential for a ship’s stability, trim, and stress distribution, but they are also one of the most challenging areas to protect. They are constantly exposed to saltwater, experience significant temperature fluctuations, and accumulate sediment, all of which accelerate corrosion. Without a robust protective coating, the steel structure is vulnerable to uniform corrosion, severe pitting, and cracking, which can compromise the vessel’s structural integrity. Therefore, applying and maintaining a high-performance coating is a crucial aspect of ship maintenance and a fundamental requirement for safe operation.

The Duel Function of Ballast Tanks

Ballast tanks are more than just empty spaces; they are a dynamic part of the ship’s operational systems. Their role includes:

| Function | Description | Impact on Coating |

|---|---|---|

| Stability & Trim | Water is pumped in or out to manage the ship’s draft and stability, especially during cargo operations and varying sea conditions. | The coating must withstand the constant flow and pressure of saltwater. |

| Structural Stress | They help distribute the load and stress across the hull, particularly in large vessels like tankers and bulk carriers. | The coating needs to be flexible enough to handle minor flexing of the steel structure without cracking. |

| Environmental Factors | The enclosed space creates a highly humid marine environment, even when empty, leading to constant condensation and corrosion risk. | A high-quality epoxy coating provides a barrier against both liquid and atmospheric moisture. |

The introduction of Ballast Water Treatment Systems (BWTS) has also added another layer of complexity. Some treatment methods can make the ballast water even more corrosive, making the selection of a compatible and resistant coating more critical than ever. Investing in superior corrosion control is the only way to ensure the longevity of these vital structural components.

What Key IMO PSPC Regulations Govern Ballast Tank Coatings?

Navigating the web of maritime regulations can be daunting. Ship owners and operators often worry if their chosen coating system and application procedures meet the strict international standards. Failure to comply with the IMO PSPC not only risks sanctions from classification societies but also jeopardizes the vessel’s 15-year target lifespan, leading to premature and expensive maintenance cycles.

The International Maritime Organization’s (IMO) Performance Standard for Protective Coatings, outlined in Resolution MSC.215(82), is the definitive regulation for ballast tank coatings. Its purpose is to ensure that coatings applied in dedicated seawater ballast tanks on new builds have a target service life of 15 years, classifying them as "GOOD." This standard is not merely a recommendation; it is a mandatory framework that dictates every stage of the coating process, from the steel’s condition to final inspection, ensuring a high standard of corrosion protection across the global fleet.

Breaking Down the PSPC Requirements

The PSPC is detailed and specific, leaving no room for ambiguity. Adherence is documented meticulously in the Coating Technical File (CTF), a document that stays with the vessel throughout its life. Here are the core pillars of the standard:

1. Uncompromising Surface Preparation

The standard demands a pristine surface to ensure maximum coating adhesion.

- Primary Standard: Sa 2.5 (Near White Metal Blast Cleaning) as per ISO 8501-1. This removes virtually all mill scale, rust, and foreign matter.

- Salt Contamination: Soluble salt levels on the surface must be checked and confirmed to be below 50 mg/m² of NaCl.

- Surface Profile: A sharp, angular profile of 30-75 µm is required to create a mechanical "key" for the coating.

2. The Criticality of Stripe Coating

Edges, welds, and cut-outs are notorious weak points where coatings tend to fail first.

- Mandatory Application: The PSPC mandates the application of a stripe coat to all such geometric complexities.

- Purpose: This extra layer builds up the film thickness in areas where the coating naturally thins, providing robust protection against premature rust. Our stripe coating procedure ensures these vulnerable areas are fully protected.

3. Specified Coating Thickness

The standard sets a clear minimum for the protective barrier.

- Minimum DFT: A nominal Dry Film Thickness (DFT) of 320 µm is required for most epoxy systems.

- The 90/10 Rule: This rule dictates that 90% of all thickness measurements must be greater than or equal to the specified nominal DFT, and none of the remaining 10% can be below 90% of the nominal DFT.

Compliance with these IMO Performance Standard for Protective Coatings (PSPC) requirements is the foundation for achieving the desired 15-year service life and ensuring long-term structural integrity.

Which Type of Ballast Tank Coating is Right for Your Vessel?

With various marine coatings available, selecting the optimal system for the extreme conditions inside a ballast tank can be overwhelming. Choosing an inadequate coating leads to premature failure, forcing you back into the shipyard for costly re-blasting and re-coating, erasing any initial savings and causing operational delays.

The undisputed industry standard for ballast tank coating is the two-component, high-build epoxy system. These coatings offer an unparalleled combination of durability, adhesion, and resistance to saltwater and mechanical damage. At JDmarine Paint, we specialize in advanced formulations like our JDH836 Solvent-Free Aluminum Iron Epoxy Anti-Rust Paint, a solvent-free epoxy designed for maximum protection and ease of inspection. Solvent-free and tar-free variants are now preferred for their enhanced safety during application and reduced environmental impact. The PSPC’s preference for light-colored coatings is a key factor, as it significantly improves the visibility required for thorough inspections, making it easier for surveyors to spot potential issues like localized corrosion or blistering.

Comparing Coating System Attributes

While standard epoxies dominate, it’s essential to understand why they are the preferred choice over other potential systems.

| Coating Type | Key Advantages | Limitations & Considerations |

|---|---|---|

| Two-Component Epoxy (Solvent-Free) | Excellent water/corrosion resistance. Superior adhesion. High-build (achieves DFT in fewer coats). Light colors aid inspection. | Strict requirements for surface preparation and environmental conditions during application (temperature, humidity). |

| Modified Epoxies (e.g., Novolac) | Offer enhanced chemical resistance. May be specified if the vessel carries aggressive cargoes or has unique operational needs. | Can be more expensive and may have more complex application requirements. Often overkill for standard ballast tanks. |

| Alternative Technologies | Other systems exist, but they are rarely used for newbuild ballast tanks due to the stringent PSPC requirements. | May not have the proven track record or third-party certification (e.g., from a classification society like DNV or Lloyd’s Register) to meet the 15-year target life. |

Ultimately, for new builds and major refurbishments aiming for PSPC compliance, a light-colored, high-solid or solvent-free, two-component epoxy coating is the most reliable and cost-effective solution for long-term corrosion control. It provides the durability needed to withstand the harsh marine environment and meets the rigorous shipbuilding standards set by the IMO.

Conclusion

Investing in a premium ballast tank coating and its meticulous application is not an expense; it is a direct investment in your vessel’s future structural integrity and profitability.

![]()