Finding the Best Marine Paint for Your Aluminum Hull

Is your aluminum hull’s paint failing? The wrong coating leads to costly corrosion. This guide reveals the secrets to a durable, professional finish, protecting your investment for years.

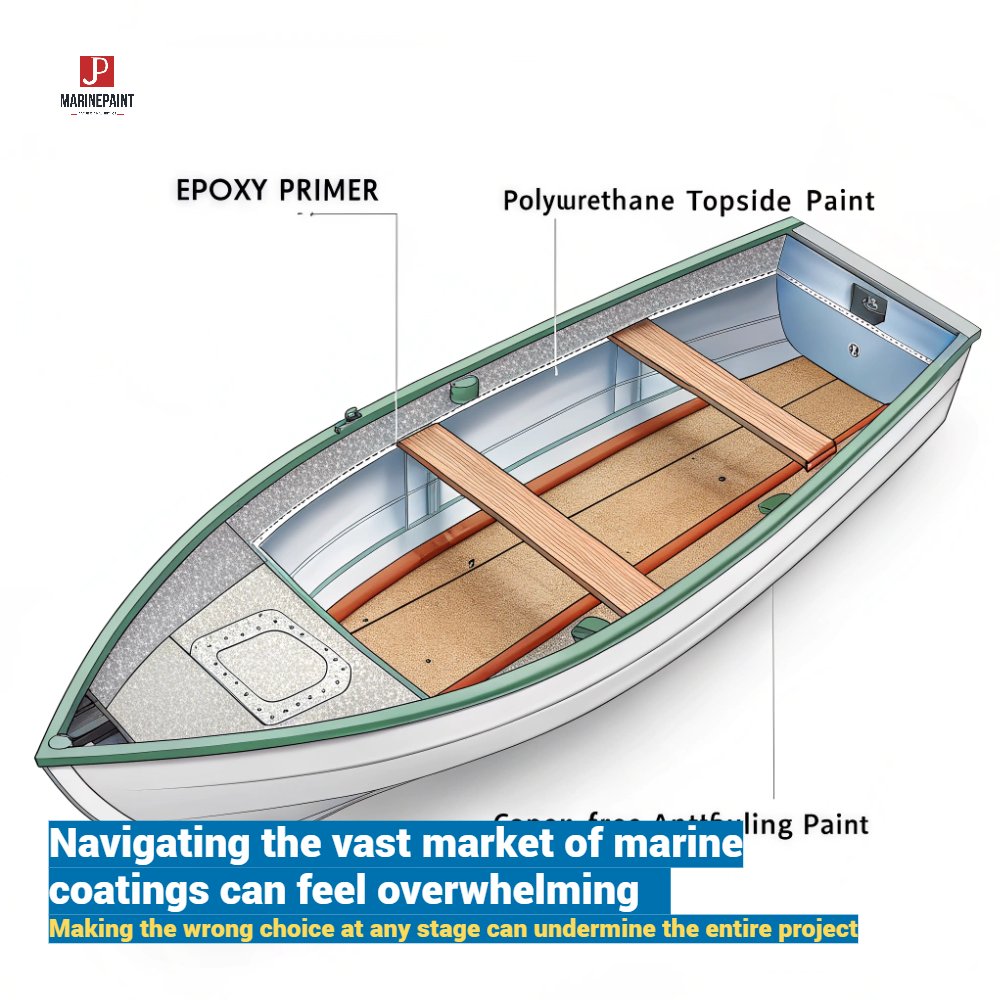

The best marine paint for an aluminum hull is not a single product, but a complete system designed to work together. The process starts with a high-adhesion primer specifically for non-ferrous metals, which is non-negotiable for a lasting finish [13]. Epoxy primers are the superior choice, as they create a robust, impermeable barrier that prevents corrosion and ensures subsequent paint layers stick properly [11]. For surfaces above the waterline, a polyurethane or acrylic topcoat provides essential UV resistance, durability, and a high-gloss aesthetic finish [3][15]. Below the waterline, the most critical choice is a copper-free antifouling paint [30]. Using traditional copper-based bottom paints on aluminum will cause severe understanding galvanic corrosion, a destructive electrochemical reaction that can compromise the hull’s integrity. A high-quality, tin-free, self-polishing antifouling paint is the ideal solution to prevent marine growth without damaging your hull [1].

![[Image Placeholder]**Prompt:** A gleaming aluminum boat hull, half of it freshly painted with a vibrant blue marine paint, showcasing a perfect finish under bright sunlight. [Image Placeholder]**Prompt:** A gleaming aluminum boat hull, half of it freshly painted with a vibrant blue marine paint, showcasing a perfect finish under bright sunlight.](https://jdmarinepaint.com/wp-content/uploads/2025/07/a-gleaming-aluminum-boat-hull-half-of-it-freshly-2.png)

Now that you understand the basic components, let’s explore why your aluminum hull demands this specialized approach and break down the best product types for each application.

Why Your Aluminum Hull Needs a Specialized Marine Paint System?

Have you ever meticulously painted your aluminum boat, only to watch it bubble and peel in a frustratingly short time? This isn’t just an eyesore; it’s a sign of failure in protection. Poor paint adhesion leaves your hull vulnerable to the harsh marine environment. In saltwater, this vulnerability is amplified. Using the wrong paint—especially one containing copper—can trigger a destructive process called galvanic corrosion, which can literally eat away at your hull. Understanding the unique chemical properties of aluminum is the first step to preventing this damage. A specialized paint system isn’t a luxury; it’s an essential defense for the structural integrity and value of your vessel.

An aluminum hull requires a specialized marine paint system primarily because aluminum is a reactive, non-ferrous metal [13]. When exposed to oxygen, it instantly forms a thin, tough layer of aluminum oxide. While this oxide layer offers minor corrosion protection, it creates a very smooth, non-porous surface that prevents most standard paints from forming a strong mechanical bond, leading to inevitable peeling and flaking. Furthermore, aluminum is highly susceptible to galvanic corrosion when in contact with a more "noble" metal (like copper) in the presence of an electrolyte (like saltwater). If a copper-based antifouling paint is applied, the aluminum hull becomes the anode in an electrochemical cell and rapidly corrodes. Therefore, a specialized system using a high-adhesion primer to bond with the aluminum oxide and strictly copper-free paints is absolutely essential for long-term protection [30].

The Best Types of Marine Paint for Aluminum Hulls?

Navigating the vast market of marine coatings can feel overwhelming. You know you need a complete system, but which specific primer, topside paint, and bottom paint are truly the best for your aluminum boat? Making the wrong choice at any stage can undermine the entire project. A weak primer means poor adhesion for every subsequent coat. A low-quality topside paint will quickly fade, chalk, and crack under the relentless sun. And, as we’ve established, the wrong bottom paint can cause catastrophic damage to the hull itself. To eliminate the guesswork, we will now break down the ideal paint types for each part of your aluminum hull, from the critical primer foundation to the final protective topcoats, empowering you to select your products with confidence.

The best marine paint for aluminum hulls is a cohesive, multi-layer system. This system always begins with a high-adhesion primer formulated for non-ferrous metals. Following the primer, a durable and UV-resistant topside paint is applied to all surfaces above the waterline. For the hull below the waterline, a specialized, completely copper-free antifouling paint is required to prevent marine growth without causing galvanic corrosion [30]. Each layer serves a distinct purpose, and together they provide comprehensive protection.

The Critical First Layer: Best Primers for Aluminum Hulls

A high-quality primer is the non-negotiable foundation of any successful paint job on aluminum [13]. It serves two primary functions: first, it chemically etches into the aluminum oxide layer to create a tenacious bond that subsequent coats can adhere to. Second, it forms a waterproof barrier to seal the metal off from the corrosive effects of moisture and salt. Without a proper primer, any paint applied over it is destined to fail.

-

Epoxy Primers: These are widely considered the gold standard for aluminum. Epoxy primers are two-part coatings that cure to an incredibly hard, durable, and non-porous film. Their superior adhesion and corrosion resistance create a truly impermeable barrier between the aluminum and the environment. Products like our JDH835 Aluminum Iron Epoxy Anti-Rust Paint or JDH815 Iron Oxide Red Epoxy Primer are excellent examples, engineered to provide a robust foundation for the entire paint system [6][10][11].

-

Alkyd Anti-Rust Primers: Modern alkyd primers also offer a reliable and effective solution. They are known for their excellent adhesion and anti-rust properties [4][9]. A product like JDC53-35 Aluminum Iron Alkyd Anti-Rust Paint is a dependable choice that provides great protection and a solid base for subsequent topcoats [2][7].

Best Topside Marine Paint for Aluminum Hulls: Protection Above the Waterline

Topside paint is what gives your boat its color and shine, but its role is far more than cosmetic. Applied over the primer on the hull and superstructure above the waterline, its primary job is to protect against UV radiation, weathering, abrasion, and chemicals, all while maintaining its appearance.

-

Polyurethane Topcoats: For a premium, long-lasting finish, polyurethane is the top choice. These two-part coatings, like our JD908 Acrylic Polyurethane Topcoat Non-Yellowing Resistant, offer exceptional gloss retention, superior durability, and excellent resistance to chemicals and abrasion. Their non-yellowing properties ensure your boat looks great for seasons to come [3][15].

-

Alkyd and Acrylic Hull Paints: These single-part paints are versatile, user-friendly options that provide a flexible and decorative finish. They offer very good weather resistance and are easier to apply and repair than two-part polyurethanes. Our JDC43-31 Alkyd Hull Paint and JDB902 Acrylic Hull Paint deliver a brilliant, protective finish with excellent flow and coverage [3][5][9].

Best Antifouling Marine Paint for Aluminum Hulls (Bottom Paint)

Antifouling paint (or bottom paint) is applied to the hull below the waterline to prevent marine organisms like barnacles, algae, and slime from attaching to the hull [30]. A fouled hull increases drag, which significantly reduces speed and fuel efficiency.

When painting an aluminum hull, it is absolutely critical to use a formula that is 100% free of cuprous oxide (copper). As mentioned, copper will initiate galvanic corrosion and destroy your hull.

- Tin-Free Self-Polishing Antifouling Paints: These are among the most effective and modern copper-free options. As the boat moves through the water, the paint slowly wears away or "polishes," continuously exposing a fresh layer of biocide. This provides consistent, long-lasting protection against fouling. Our JD753 Tin-free self-polishing antifouling paint is specifically designed to provide this reliable, copper-free protection for aluminum vessels [1].

| Hull Area | Primary Goal | Recommended Paint Type | JDmarine Paint Example |

|---|---|---|---|

| Entire Hull (Bare) | Adhesion & Corrosion Barrier | Epoxy Primer | JDH835 Aluminum Iron Epoxy Anti-Rust Paint |

| Topside (Above Water) | UV Protection & Aesthetics | Polyurethane Topcoat | JD918 Acrylic Polyurethane Hull Paint (Yellowing resistance) |

| Bottom (Below Water) | Anti-Marine Growth | Copper-Free Antifouling | JD753 Tin-free self-polishing antifouling paint |

How to Apply Marine Paint to an Aluminum Hull: A Step-by-Step Guide?

You’ve selected the best marine paint for your aluminum hull, but the job is only half done. Are you worried that one wrong move during application could waste all your time, money, and effort? Even the most advanced marine coating will fail if the surface isn’t prepared correctly. Skipping crucial steps like thorough degreasing or proper sanding can lead to peeling and chipping within a single season, forcing you to strip everything off and start over. Don’t let that happen. By following this clear, step-by-step guide, you can execute each phase of the process correctly and achieve a professional, long-lasting finish that provides maximum protection.

Applying marine paint to an aluminum hull is a meticulous process where surface preparation is paramount to success [27]. The first critical step is to thoroughly clean and degrease the entire surface to remove all salt, oil, grease, and other contaminants that inhibit adhesion [8]. Following cleaning, the aluminum must be mechanically abraded, either by sanding or sandblasting, to create a textured surface profile for the primer to grip; achieving a professional standard like Sa 2.5 is ideal for ensuring maximum adhesion [7][20][24]. You can find more information on these professional surface preparation standards. Immediately after abrading and cleaning the dust, apply a high-adhesion epoxy or recommended alkyd primer, strictly following the manufacturer’s instructions for mixing, application, and recoat times [8][14]. Once the primer system has fully cured, you can apply your chosen topside or antifouling paint. This typically requires two or more thin coats to achieve the specified dry film thickness needed for robust protection [4][13][19]. For those who feel the process is too complex, consulting a certified professional via organizations like the American Boat & Yacht Council (ABYC) is a wise investment.

Step 1: Surface Preparation – The Most Important Step

Success is 90% preparation. Start by scrubbing the hull with a quality marine-grade degreaser and fresh water to remove all traces of oil, wax, and other surface contaminants. Rinse thoroughly and allow the hull to dry completely. This cleaning step ensures that you are not sanding contaminants into the metal surface in the next step [8][10].

Step 2: Sanding and Abrading the Aluminum for Maximum Adhesion

Aluminum’s natural oxide layer is too smooth for paint to stick to reliably. You must create a mechanical "profile"—a series of microscopic peaks and valleys—for the primer to lock into. For DIY applications, use 80-120 grit sandpaper with a dual-action or orbital sander. For professional results, abrasive blasting to an Sa 2.5 standard is the best method [7][20][24]. The goal is a uniformly dull, abraded surface. Once sanded, wipe the surface clean with a solvent wipe recommended by the primer manufacturer to remove all sanding dust.

Step 3: Applying the Best Primer to Your Aluminum Hull

Time is of the essence. You should apply the primer as soon as possible after abrading and cleaning, before the aluminum has a chance to re-oxidize. Meticulously follow the manufacturer’s instructions for mixing ratios (for two-part epoxies) and induction times (the waiting period after mixing) [4]. Apply the primer evenly with a brush, roller, or sprayer to the recommended thickness. Pay close attention to the specified recoat windows to ensure a proper chemical bond between primer coats [14].

Step 4: Applying the Final Marine Paint Coats

After the primer has cured for the recommended time, you can apply your topcoat or bottom paint. As with the primer, follow the paint manufacturer’s guidelines. Apply two to three thin, even coats rather than one thick coat. This method results in a stronger, more durable finish and reduces the risk of runs or sags. Allow for the proper drying time between coats for the best results [13][19].

Conclusion: Ensuring a Long Life with the Best Marine Paint System

Proper preparation, a high-adhesion epoxy primer, and the right copper-free antifouling paint are key. This complete system is the best investment for protecting your aluminum hull for years.

Frequently Asked Questions (FAQs) About Marine Paint for Aluminum Hulls

What is the best primer to use on an aluminum boat?

An epoxy primer is the best choice for a bare aluminum boat. It offers superior adhesion to the metal and creates a waterproof barrier that provides the best corrosion protection, serving as a perfect base for the rest of the paint system.

Do you have to sand an aluminum boat before painting?

Yes, sanding is an absolutely essential step [8]. Aluminum develops a smooth oxide layer that paint cannot stick to. Sanding or abrading the surface creates a mechanical profile that allows the primer to form a strong, lasting bond.

Why can’t I use copper-based antifouling paint on an aluminum hull?

When aluminum and copper are put together in saltwater, a powerful electrochemical reaction called galvanic corrosion occurs. This reaction will rapidly corrode and pit the aluminum hull, causing severe structural damage. You must only use copper-free antifouling paints on aluminum.

How do I prepare a previously painted aluminum hull for new paint?

First, remove any flaking or peeling paint with a scraper. Then, sand the entire surface to feather the edges of the existing paint and abrade any exposed aluminum. Clean the surface thoroughly to remove all dust and contaminants. Apply a suitable primer to any bare aluminum spots, allow it to cure, and then you can apply your new topcoat.

![]()